0 引言

防爆柴油机以功率大、适用性强、机动性强、运输效率高等优点[1],成为目前应用广泛的井下辅助运输设备动力装置之一[2]。与稳态工况相比,瞬态工况下防爆柴油机性能会出现明显的劣化[3-7],防爆柴油机的油耗、烟度及CO排放急剧升高,并伴随转矩迟滞等现象,而造成防爆柴油机瞬态工况性能劣变的主要原因是供气量延迟导致缸内燃烧恶化、油耗和排放增加[8]。现有防爆柴油机是在地面柴油机的基础上,按照相关标准[9]进行进排气防爆改造研制而成,进气系统和排气系统加装防爆阻火器是改造的关键。相较于地面道路,煤矿井下工况更加复杂,防爆柴油机经常处于启停、加减速等瞬态工况,而防爆阻火器的加装导致柴油机进排气严重受阻[10-12],瞬态工况下进排气系统迟滞加重,瞬态工况特性恶化严重。因此,深入研究防爆柴油机瞬态工况特性对解决防爆柴油机性能恶化问题具有积极意义。本文通过建立矿用防爆柴油机稳态仿真模型和瞬态仿真模型,对矿用防爆柴油机在恒转矩变转速和恒转速变转矩2种典型瞬态工况下的动力和排放性能进行仿真分析,并对喷油提前角和防爆阻火器栅栏数量进行优化。

1 防爆柴油机稳态仿真模型

1.1 模型建立

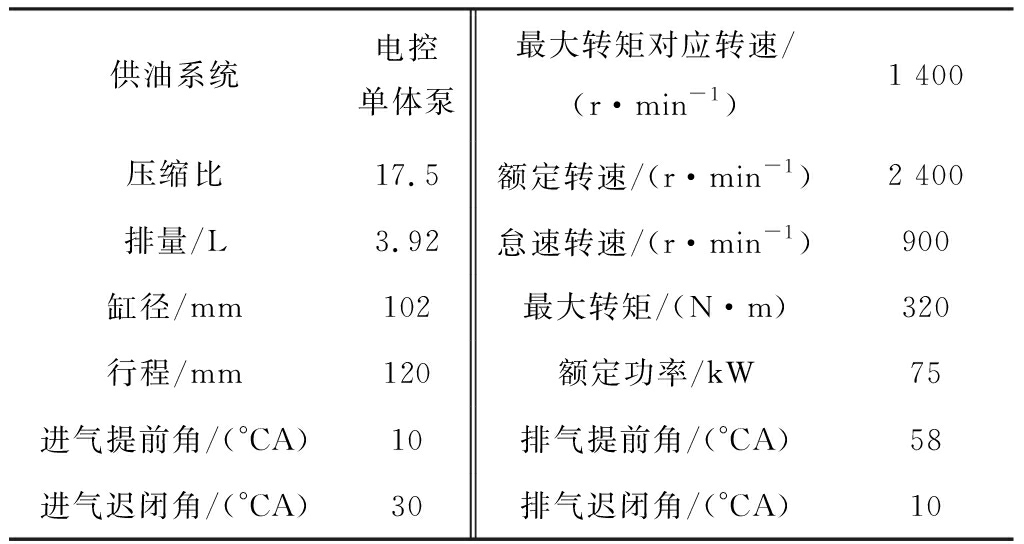

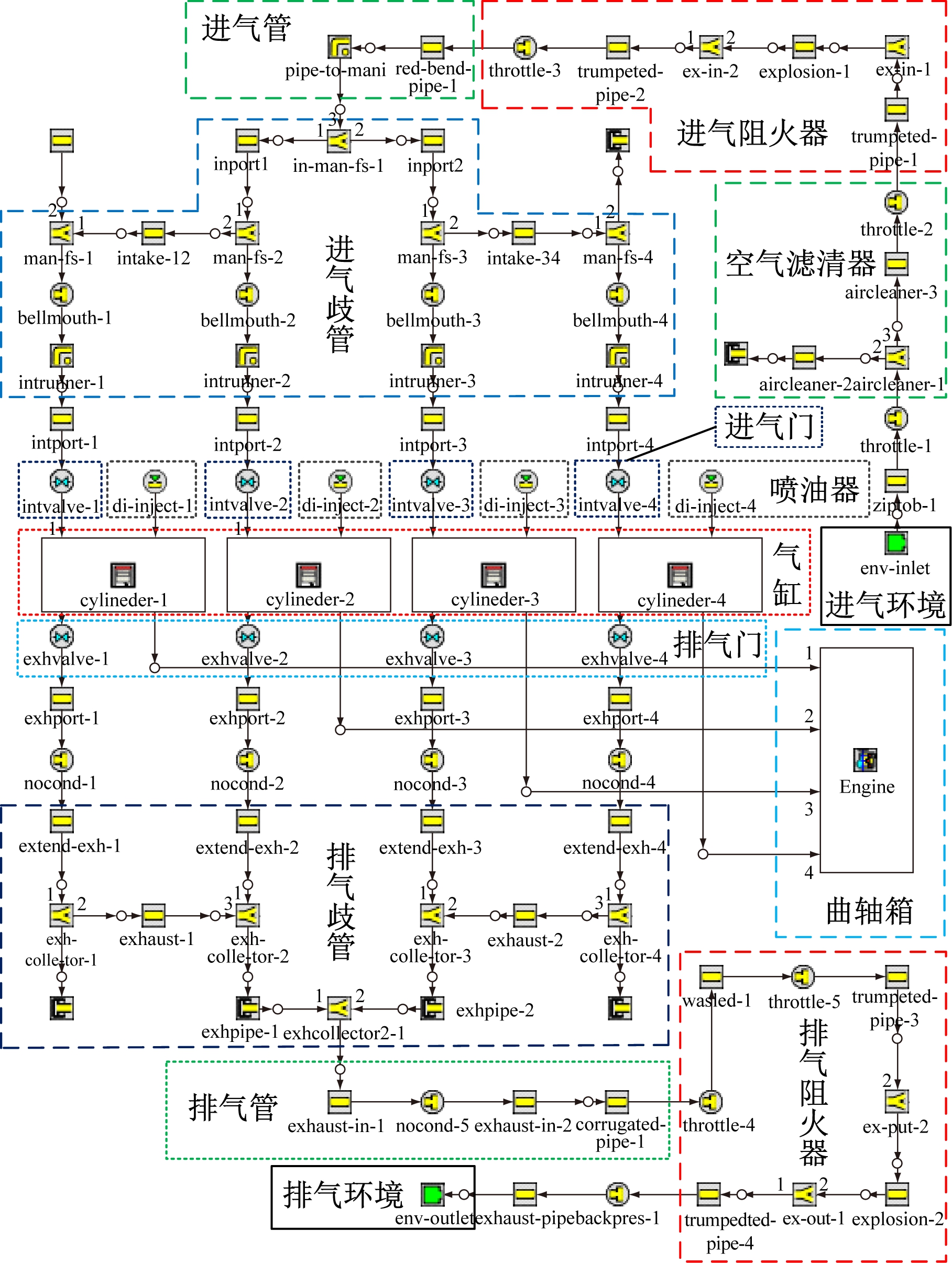

本文以YCD4J22T-100型4缸自吸柴油机(基本技术参数见表1)为样机进行防爆改造。根据防爆改造前柴油机基本技术参数(表1),利用发动机模拟软件GT-POWER建立防爆改造前柴油机稳态仿真模型,在此基础上增加进排气防爆阻火器模型。防爆改造后柴油机稳态仿真模型主要包括进排气系统、气缸、曲轴箱系统、喷油器及进排气防爆阻火器,如图1所示。

表1 防爆改造前柴油机基本技术参数

Table 1 Basic technical parameters of diesel engine before explosion-proof transformation

供油系统电控单体泵最大转矩对应转速/(r·min-1)1 400压缩比17.5额定转速/(r·min-1)2 400排量/L3.92怠速转速/(r·min-1)900缸径/mm102最大转矩/(N·m)320行程/mm120额定功率/kW75进气提前角/(°CA)10排气提前角/(°CA)58进气迟闭角/(°CA)30排气迟闭角/(°CA)10

图1 防爆柴油机稳态仿真模型

Fig.1 Steady state simulation model of explosion- proof diesel engine

1.2 模型验证

通过防爆柴油机测控平台[13]进行台架试验,得到柴油机燃油消耗率,并计算柴油机单循环喷油量:

(1)

式中:Be为柴油机燃油消耗率台架试验值,g/(kW·h);Ne为柴油机功率,kW;δ为喷油量修正系数,取值范围为1.10~1.14;i为柴油机气缸数;n为柴油机转速,r/min。

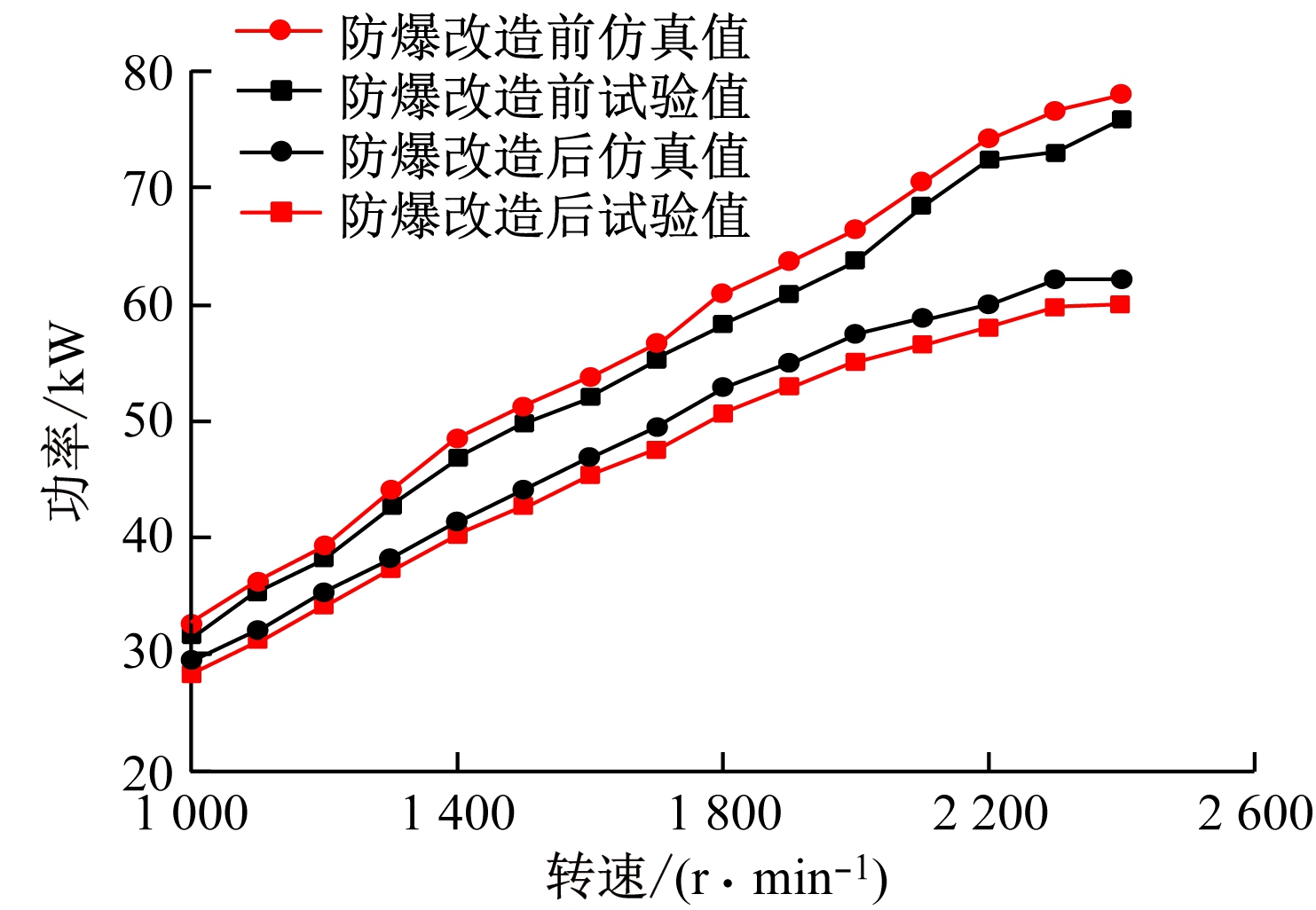

将单循环喷油量的值赋给防爆改造前后柴油机稳态仿真模型,通过仿真计算获取柴油机防爆改造前后转矩、功率等仿真值,并与台架试验获得的试验值进行对比,如图2所示。可看出最大误差均在5%以内,说明防爆柴油机稳态仿真模型及其相关参数设置较合理。

(a) 转矩

(b) 功率

图2 柴油机防爆改造前后仿真值与试验值对比

Fig.2 Comparison of simulation and test values before and after explosion-proof transformation

2 防爆柴油机瞬态仿真模型

恒转速变转矩工况和恒转矩变转速工况是2种典型的瞬态工况,启停、加减速等复杂的瞬变过程从微观上均可由这2种工况组合而成[14]。为实现防爆柴油机瞬态工况的仿真控制,利用Simulink建立防爆柴油机瞬态工况控制模型,并与防爆柴油机稳态仿真模型耦合形成防爆柴油机瞬态仿真模型。

2.1 模型建立

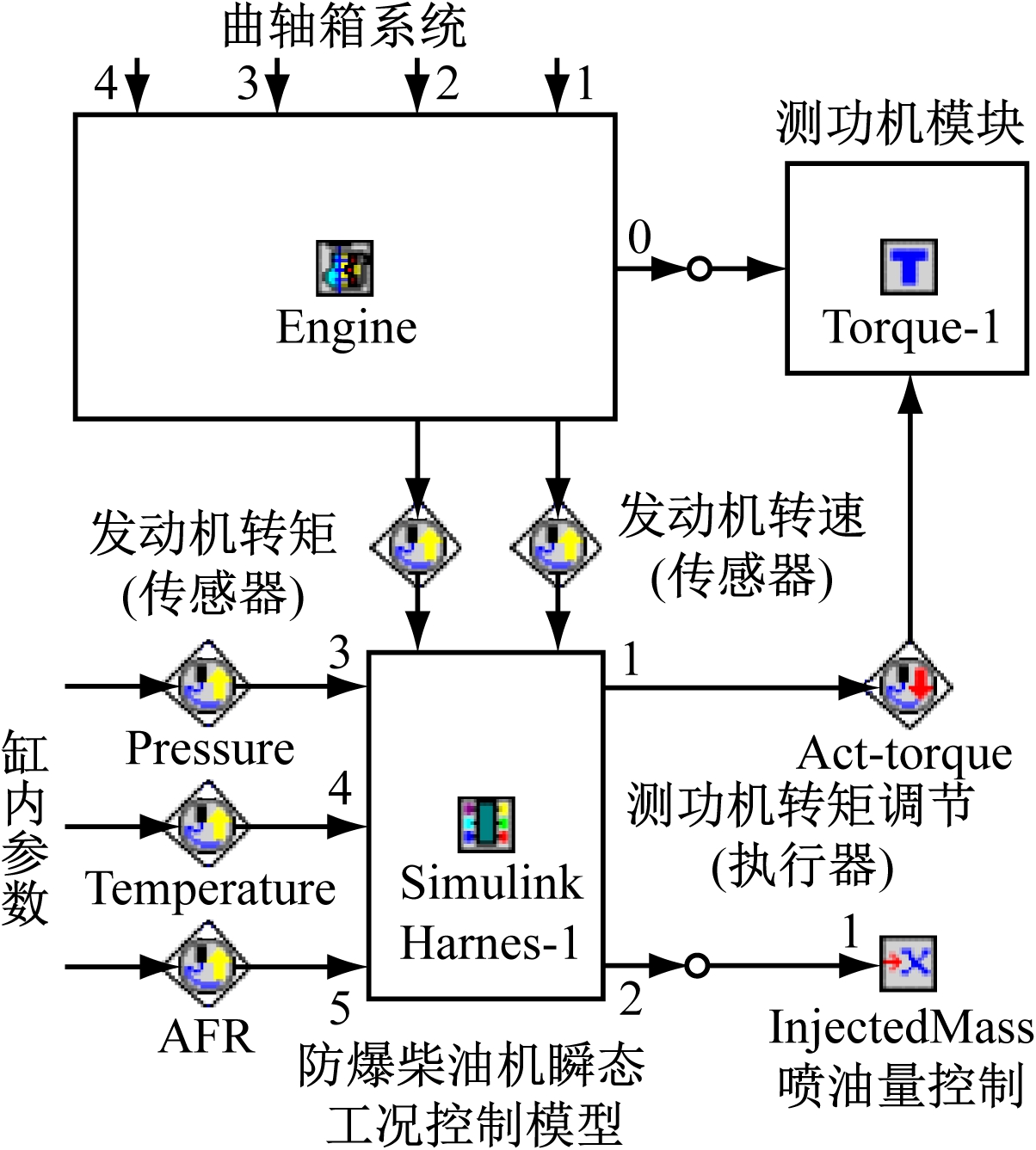

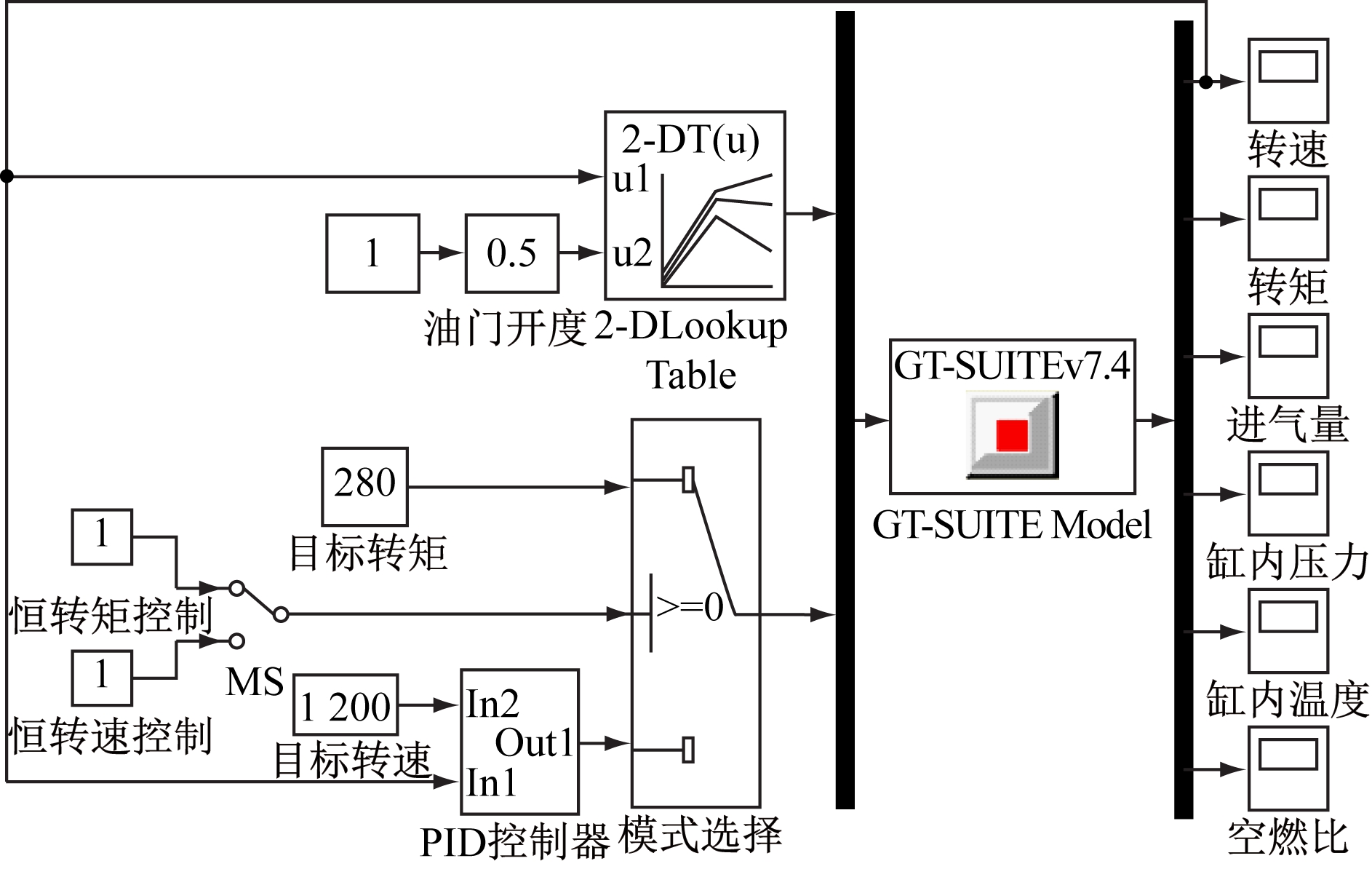

防爆柴油机瞬态仿真模型如图3所示。曲轴箱系统可实现柴油机曲轴转矩的模拟与输出;防爆柴油机瞬态工况控制模型可对曲轴箱系统输出的转矩和转速进行采集,并利用测功机模块对转矩进行PID控制;测功机模块通过测功机转矩调节器接收防爆柴油机瞬态工况控制模型发出的信号,调整测功机载荷[15]。

防爆柴油机瞬态工况控制模型如图4所示。通过MS开关进行恒转矩变转速/恒转速变转矩控制模式切换。恒转矩变转速控制将测功机的转矩保持在目标值,调节油门开度即可调节柴油机转速;恒转速变转矩控制是根据柴油机当前转速与目标转速之间差值,通过PID控制测功机的输出转矩与柴油机转矩保持一致,调节油门开度即可调节柴油机转矩并保持转速不变[16]。

图3 防爆柴油机瞬态仿真模型

Fig.3 Transient simulation model of explosion- proof diesel engine

图4 防爆柴油机瞬态工况控制模型

Fig.4 Transient condition control model of explosion- proof diesel engine

2.2 模型验证

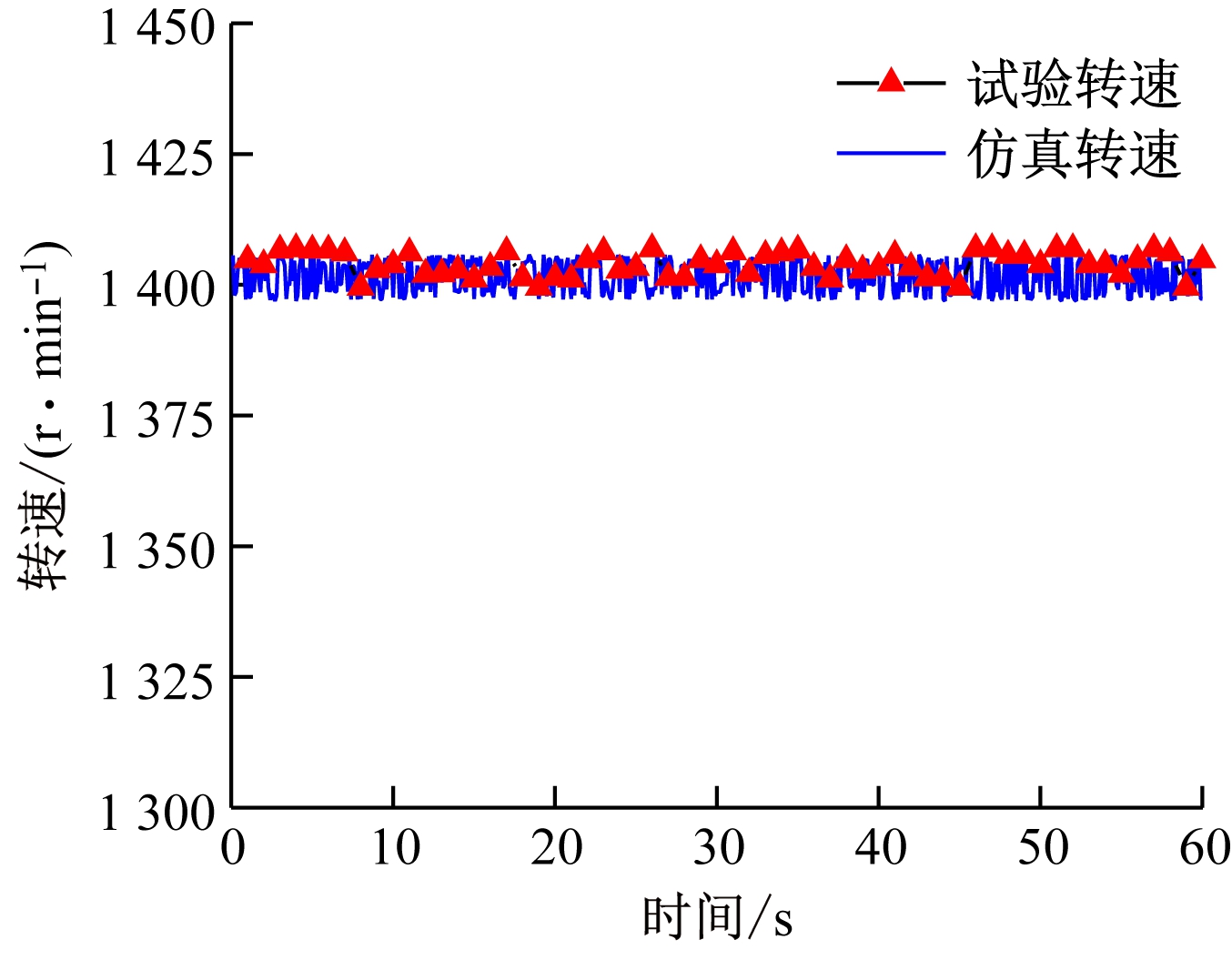

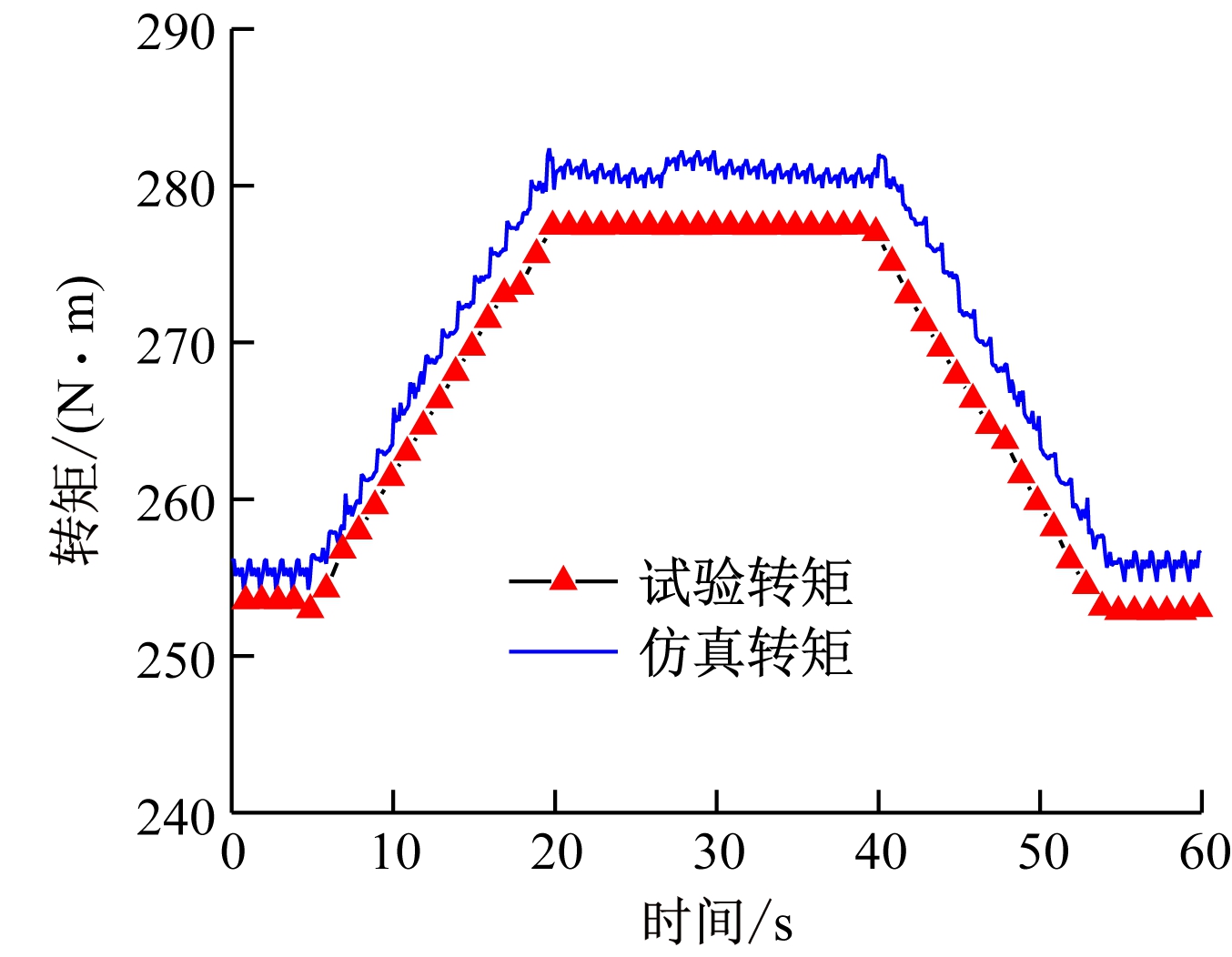

为验证防爆柴油机瞬态仿真模型模拟的准确性,以恒转速变转矩工况为例进行试验验证。首先,柴油机以1 400 r/min的恒定转速持续运行5 s,之后开始转矩变化过程,在15 s内防爆柴油机油门开度从50%增长到90%并保持20 s,接着在15 s内油门开度从90%降到50%。防爆柴油机仿真值与试验值对比如图5所示。可看出整个过程中柴油机转速保持在1 400 r/min左右,波动不大;在油门开度变化过程中,转矩仿真值与试验值最大误差在5%以内,且转矩变化趋势基本与实际工况变化趋势相符,说明防爆柴油机瞬态仿真模型具有较高的瞬态响应速度,精准度较高。

3 防爆柴油机瞬态工况特性分析

3.1 防爆柴油机恒转速变转矩瞬态工况特性

设置防爆柴油机转速为2 400 r/min,转矩变化范围为该转速下最大转矩的10%~90%,转矩变化时间分别为5,15 s。

(a) 转速

(b) 转矩

图5 防爆柴油机仿真值与试验值对比

Fig.5 Comparison of simulation and test values of explosion-proof diesel engine

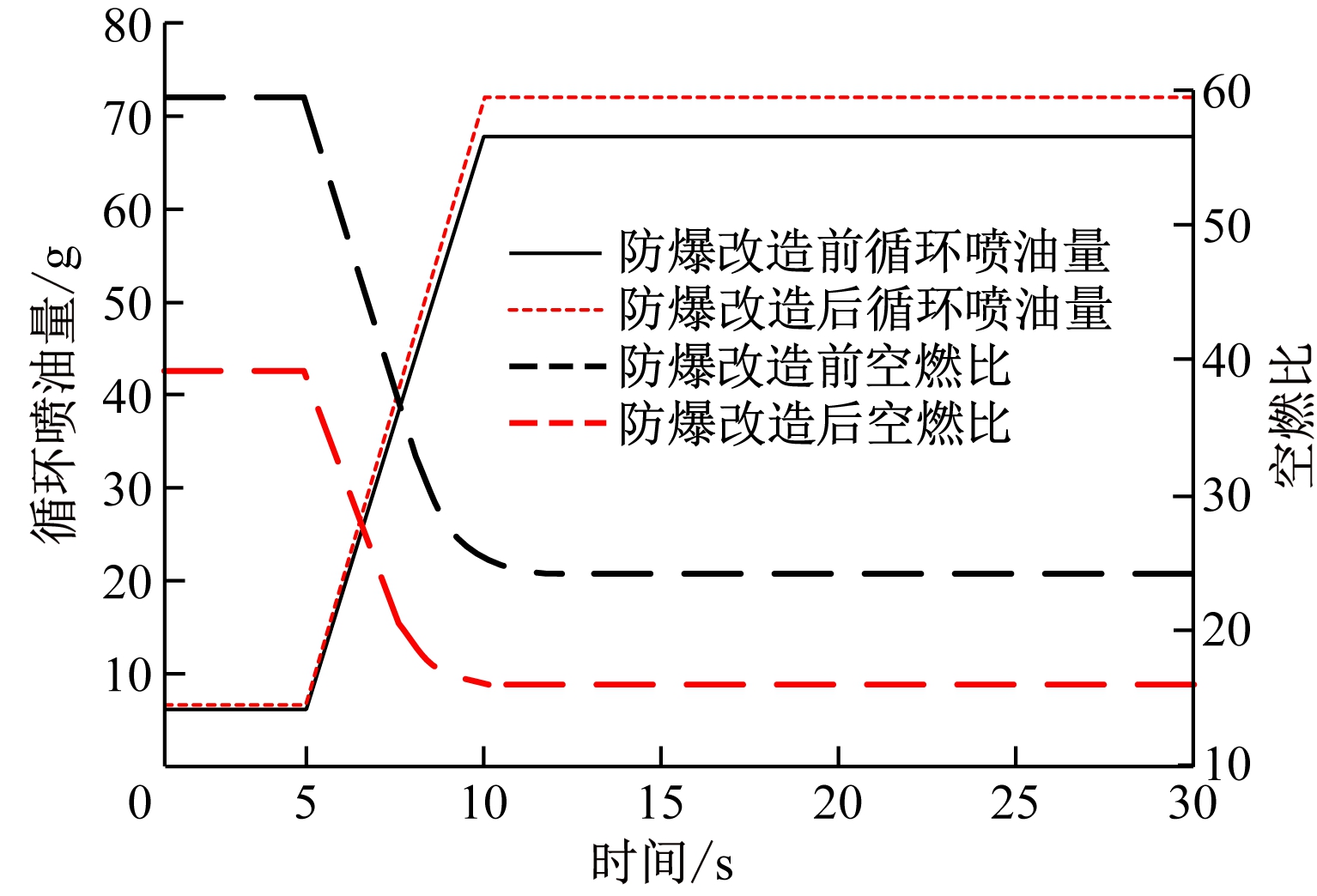

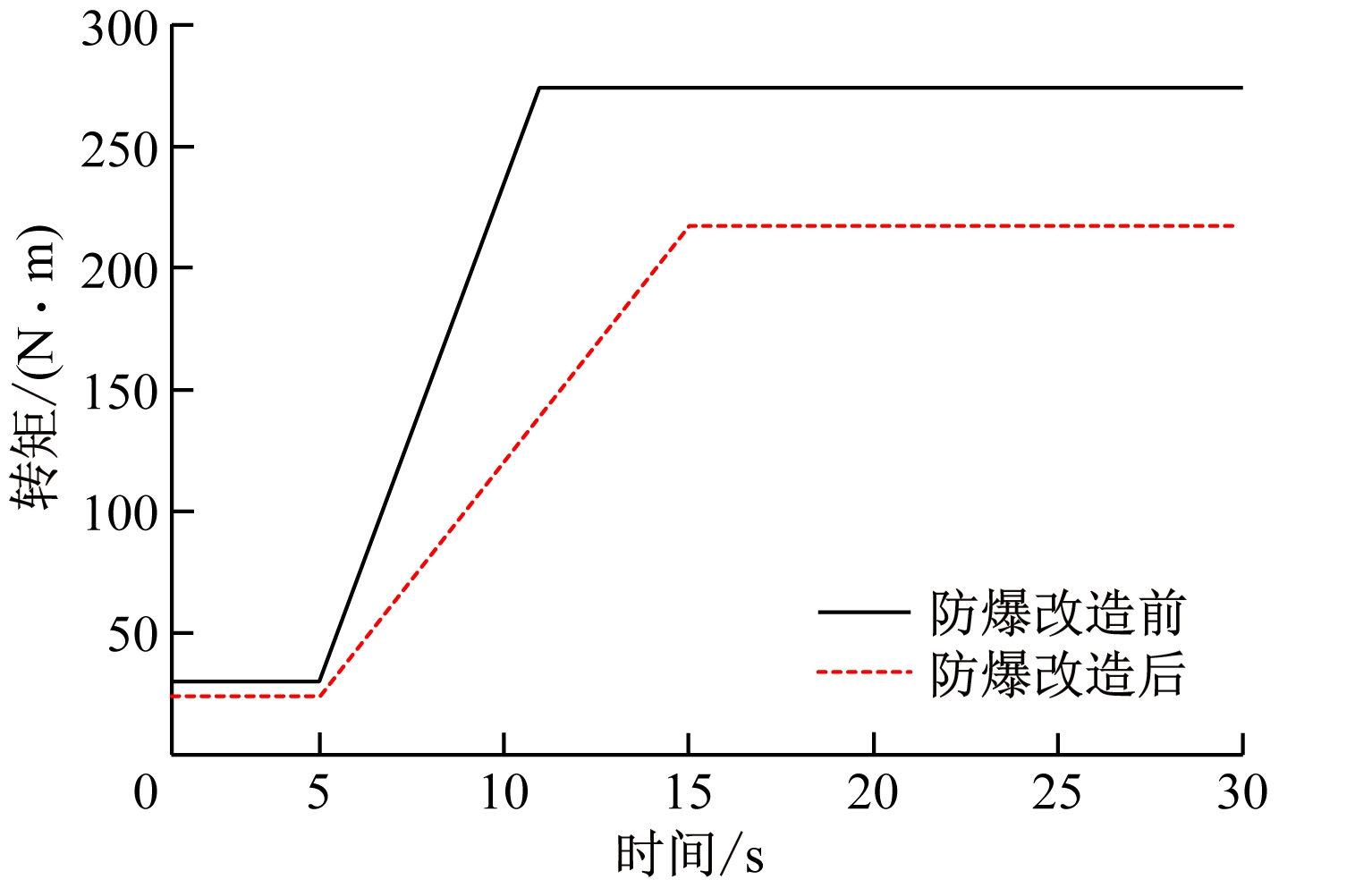

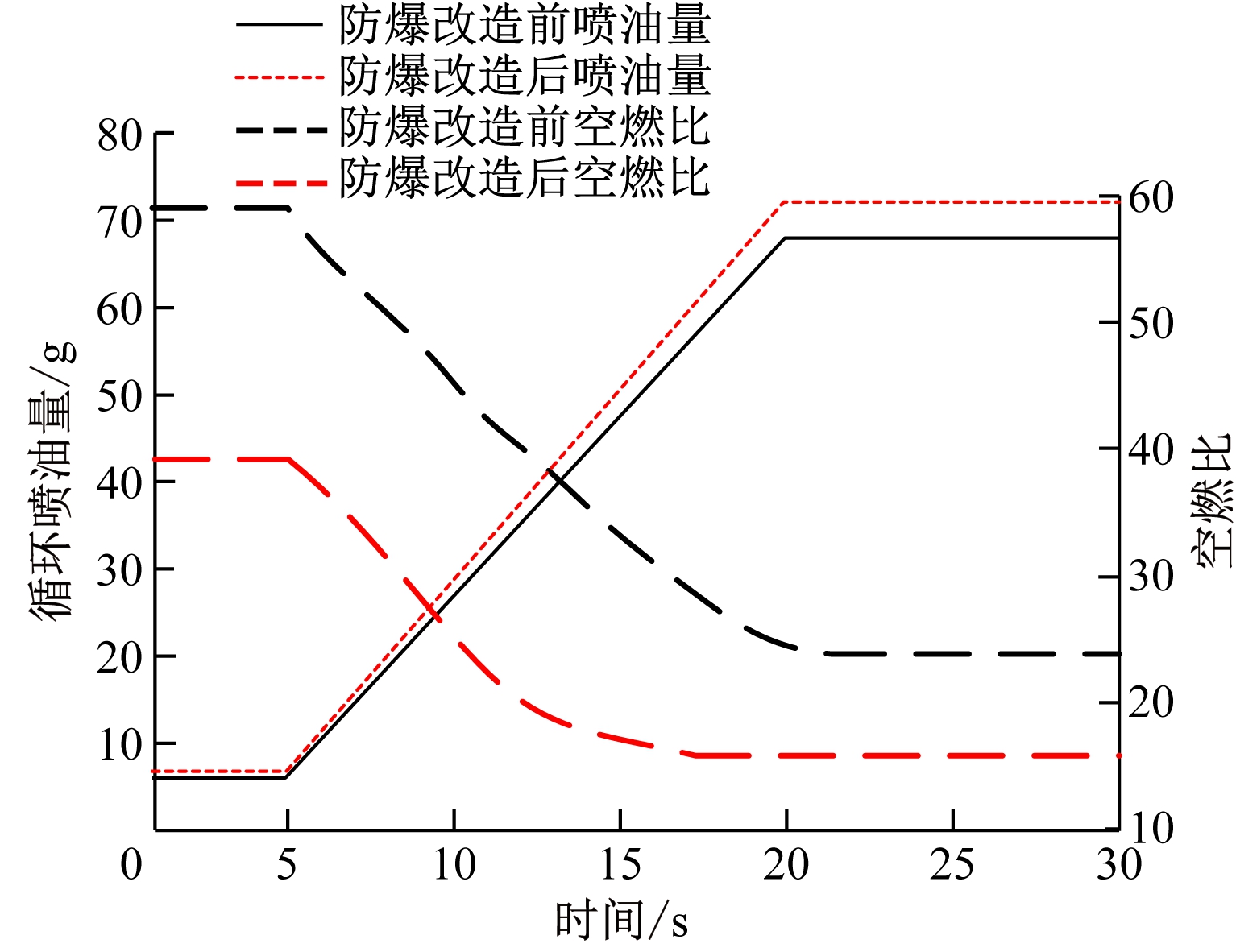

防爆改造前后柴油机瞬态工况下各参数变化曲线如图6和图7所示。可看出防爆改造后柴油机空燃比会有一定程度的下降,主要是因为加装进气防爆阻火器后进气量减小,加装排气防爆阻火器后排气受阻,缸内残余废气量增加,导致空燃比下降,同时循环喷油量的增加,也会导致空燃比下降;在柴油机转矩变化过程中,相比防爆改造前,防爆改造后柴油机空燃比下降更快,主要原因是加装进排气防爆阻火器导致柴油机进排气系统迟滞加重,无法与不断增长的循环喷油量匹配;在转矩随时间升高阶段,当循环喷油量达到稳定状态后的2 s左右,转矩才能达到稳定状态,存在转矩迟滞现象,该现象产生的原因主要是燃烧室内存在温度迟滞效应[17]和进排气系统存在响应延迟;转矩变化时间为15 s时,循环喷油量达到稳定状态后的1 s左右,转矩就达到稳定状态,说明在同一转速下,转矩升高越快,迟滞效应越严重。

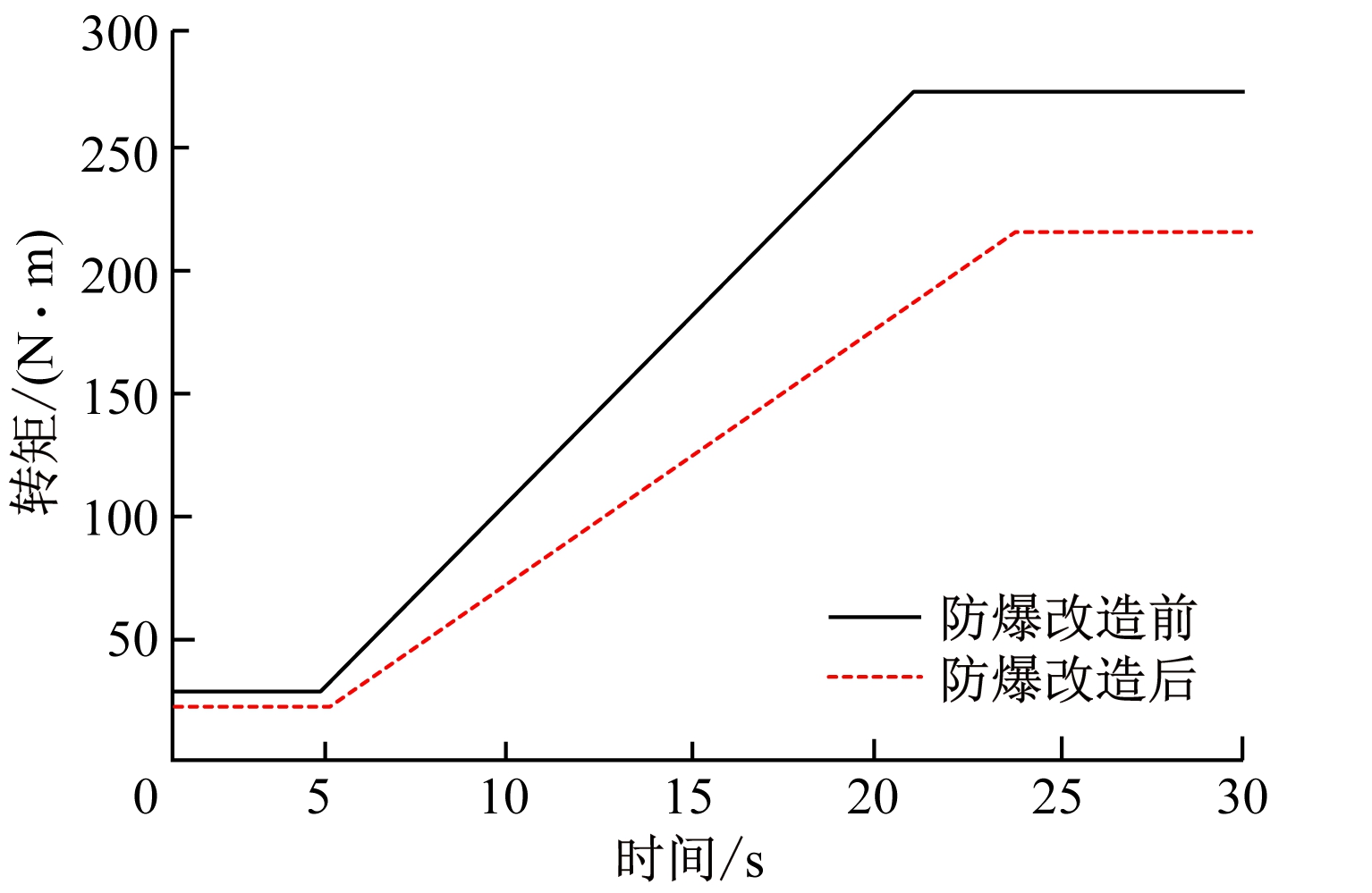

防爆改造前后柴油机缸内最大爆发压力变化曲线如图8所示。从整体趋势来看,在转速一定的情况下,随着转矩升高,柴油机缸内最大爆发压力升高;相同转速与转矩下,防爆改造后柴油机缸内最大爆发压力比防爆改造前的低;防爆改造后柴油机转矩变化时间为15 s时,转矩为152 N·m后缸内最大爆发压力就基本保持在11.5 MPa不变,而转矩变化时间为5 s时,转矩增至213 N·m后缸内最大爆发压力才基本保持在11.5 MPa左右,这主要是加装进排气防爆阻火器后进排气系统迟滞造成的。

(a) 循环喷油量与空燃比

(b) 转矩

图6 转矩变化时间为5 s时防爆改造前后柴油机 瞬态工况下各参数变化曲线

Fig.6 Variation curves of diesel engine parameters under transient conditions before and after explosion- proof transformation when torque change time is 5 s

(a) 循环喷油量与空燃比

(b) 转矩

图7 转矩变化时间为15 s时防爆改造前后柴油机 瞬态工况下各参数变化曲线

Fig.7 Variation curves of diesel engine parameters under transient conditions before and after explosion- proof transformation when torque change time is 15 s

图8 防爆改造前后柴油机缸内最大爆发压力变化曲线

Fig.8 Variation curves of the maximum burst pressure in diesel engine cylinder before and after explosion- proof transformation

3.2 防爆柴油机恒转矩变转速瞬态工况特性

设置转矩分别为120,240 N·m,转速为1 000~2 400 r/min,转速变化时间分别为5,15 s。

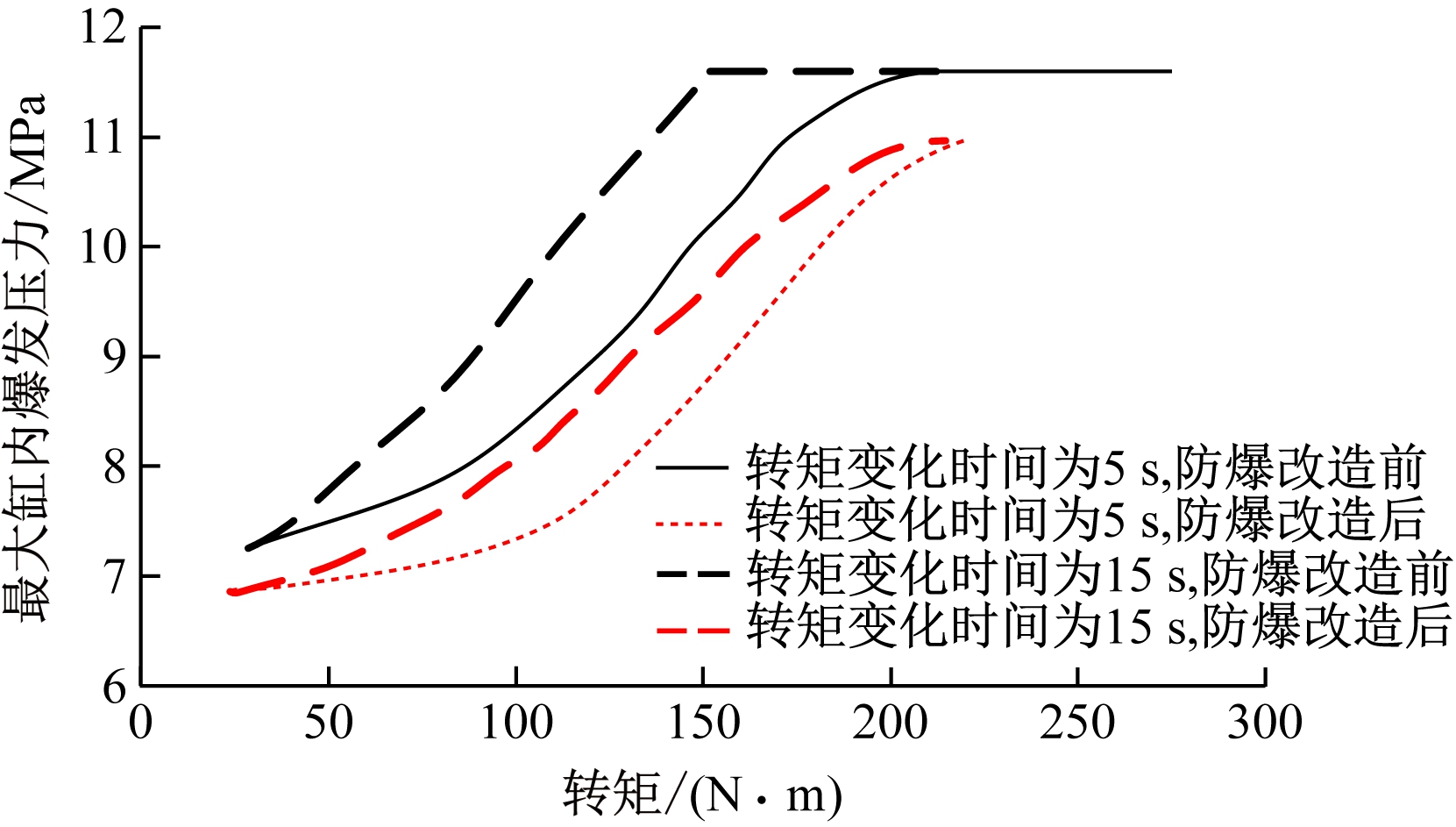

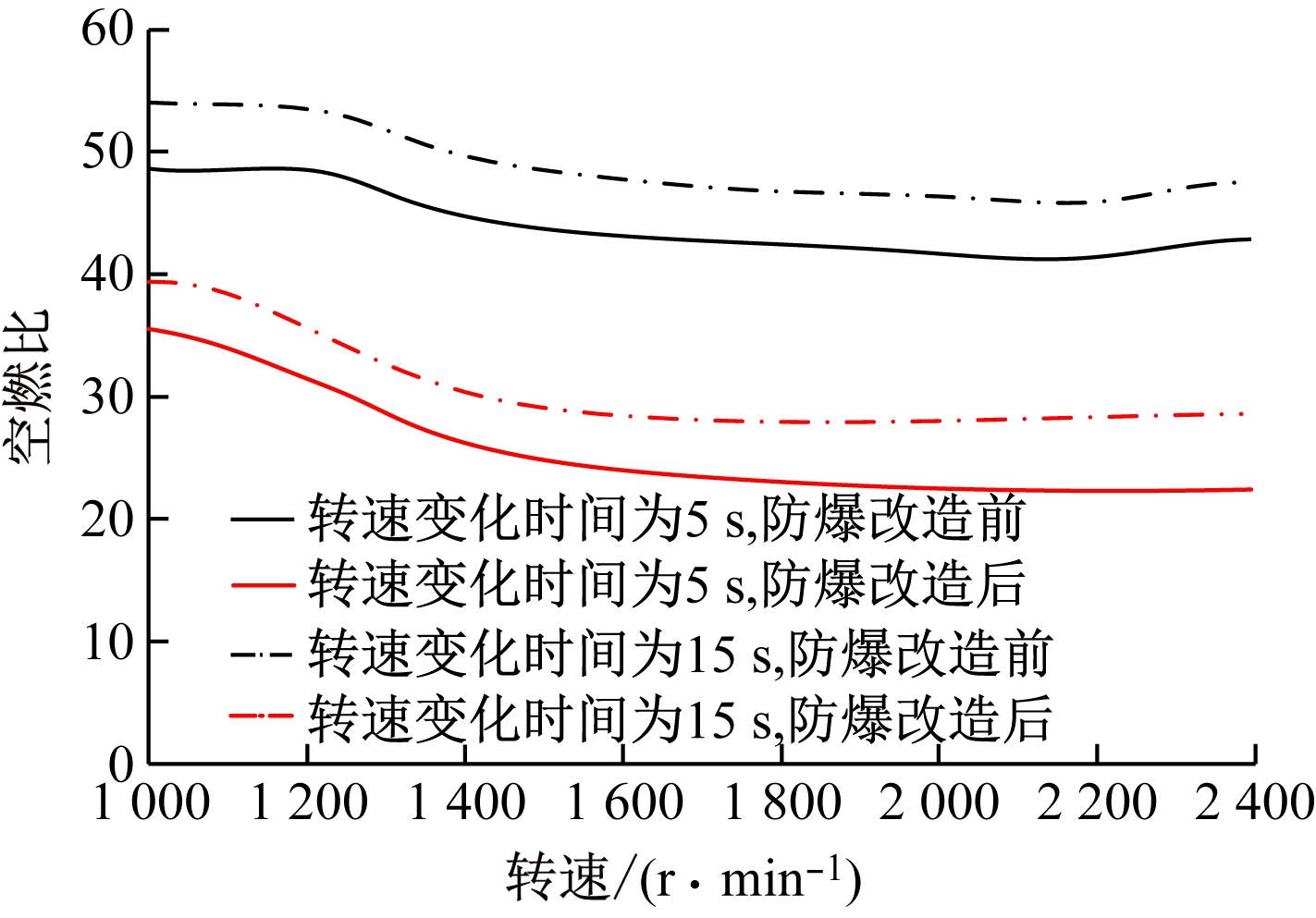

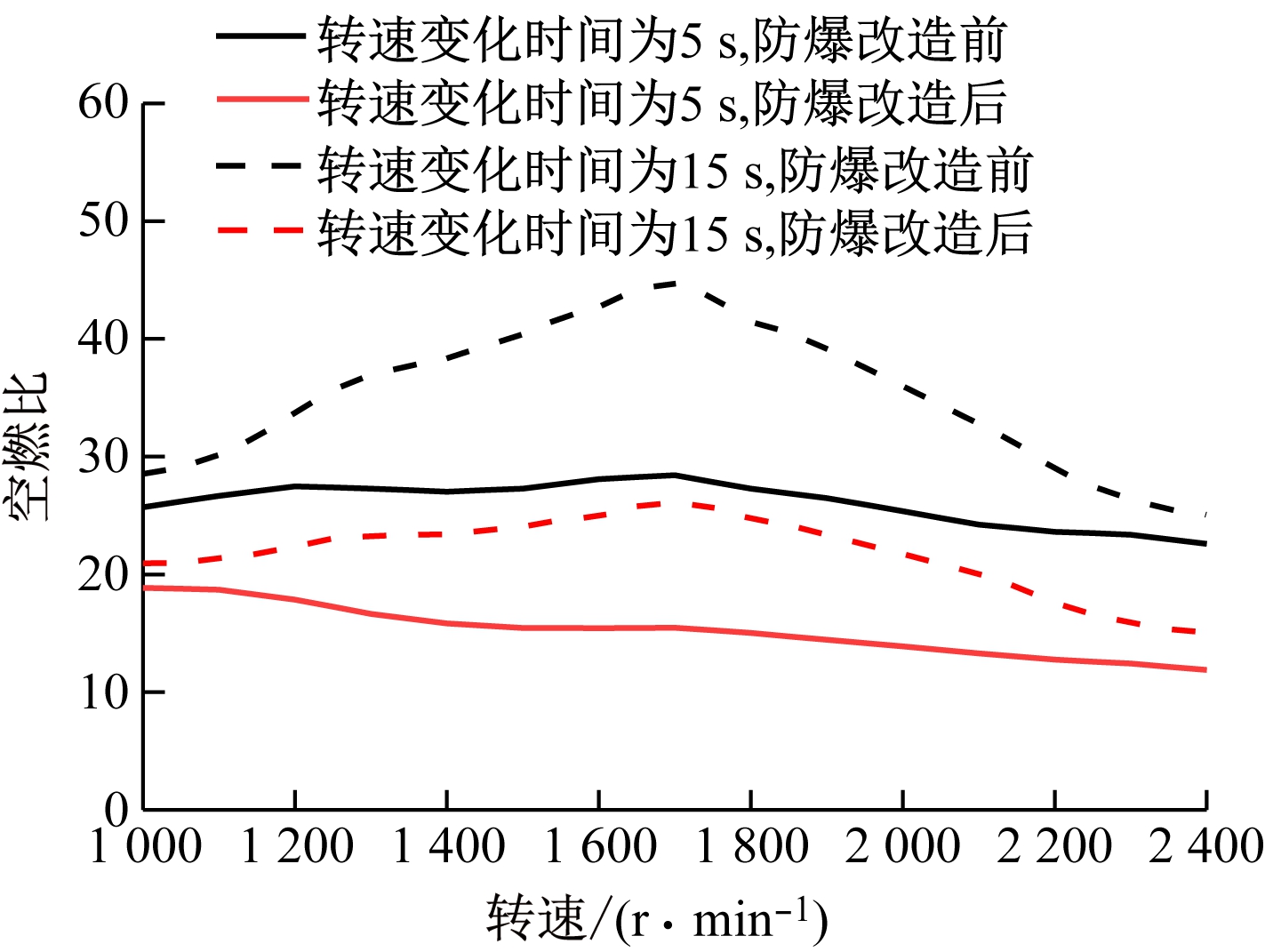

防爆改造前后柴油机空燃比变化曲线如图9所示。从整体来看,柴油机空燃比随着转速升高而下降,加装进排气防爆阻火器后空燃比随着转速升高而下降更多;转速变化时间为15 s时的空燃比比转速变化时间为5 s时的大;在转矩为240 N·m的恒转矩变转速过程中,空燃比较120 N·m恒转矩时下降很多,主要是由循环喷油量增加造成的,说明小负荷增转速过程对空燃比的影响较小。

(a) 转矩为120 N·m

(b) 转矩为240 N·m

图9 防爆改造前后柴油机空燃比变化曲线

Fig.9 Variation curves of air fuel ratio of diesel engine before and after explosion-proof transformation

4 防爆柴油机参数优化

防爆改造后柴油机特性会有所改变,因此需要对防爆柴油机部分参数进行重新设定。喷油提前角对防爆柴油机性能影响很大:喷油提前角过小,会使柴油机油耗增加,排温升高,噪声增大,甚至可能烧毁机件;喷油提前角过大,会使柴油机动力下降,可靠性降低。进排气防爆阻火器的栅栏数量也会对防爆柴油机产生较大影响:栅栏数量过少,起不到防爆效果;栅栏数量过多,会使防爆柴油机进排气阻力增大,缸内燃烧恶化,动力性能下降,排放性能变差。

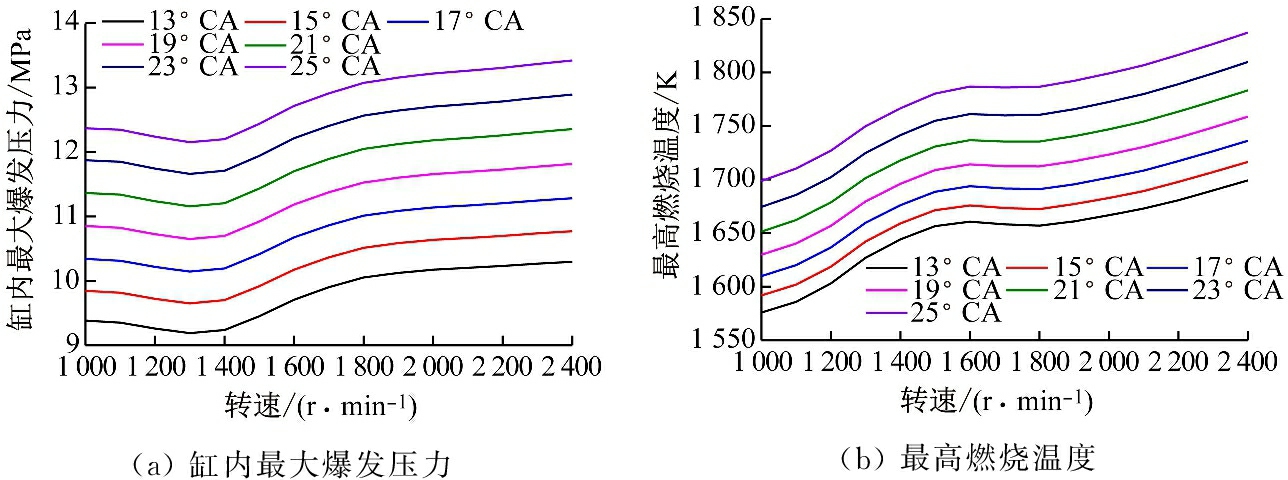

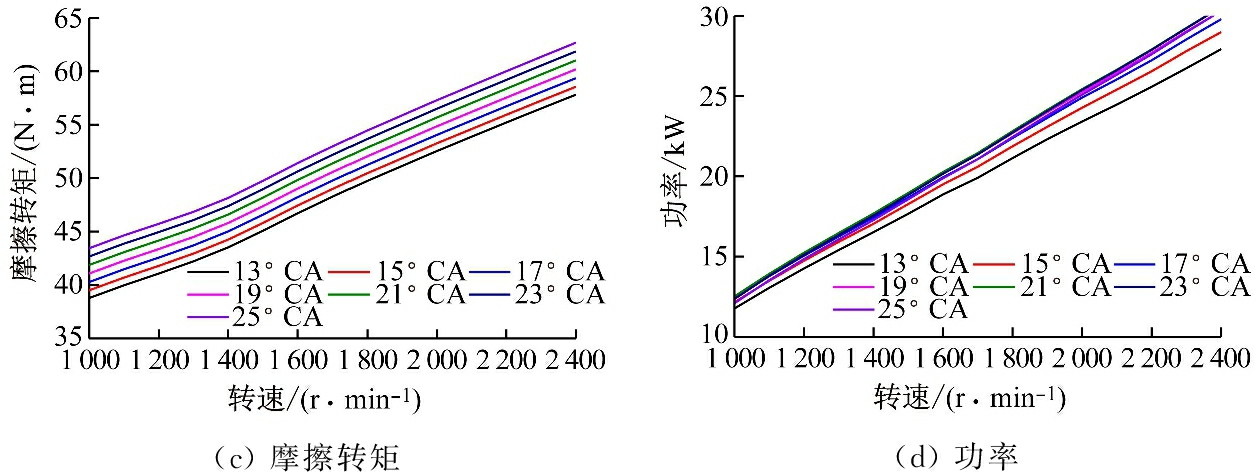

4.1 喷油提前角优化

防爆改造前柴油机喷油提前角为15°CA,仿真设置防爆改造后柴油机喷油提前角为13~25°CA,取值间隔2°CA。以转速变化时间为15 s、转矩为120 N·m的恒转矩变转速工况为例,研究喷油提前角对加装进排气防爆阻火器后的防爆柴油机主要参数的影响,结果如图10所示。

图10 不同喷油提前角下防爆柴油机主要参数变化曲线

Fig.10 Variation curves of main parameters of explosion-proof diesel engine under different injection advance angles

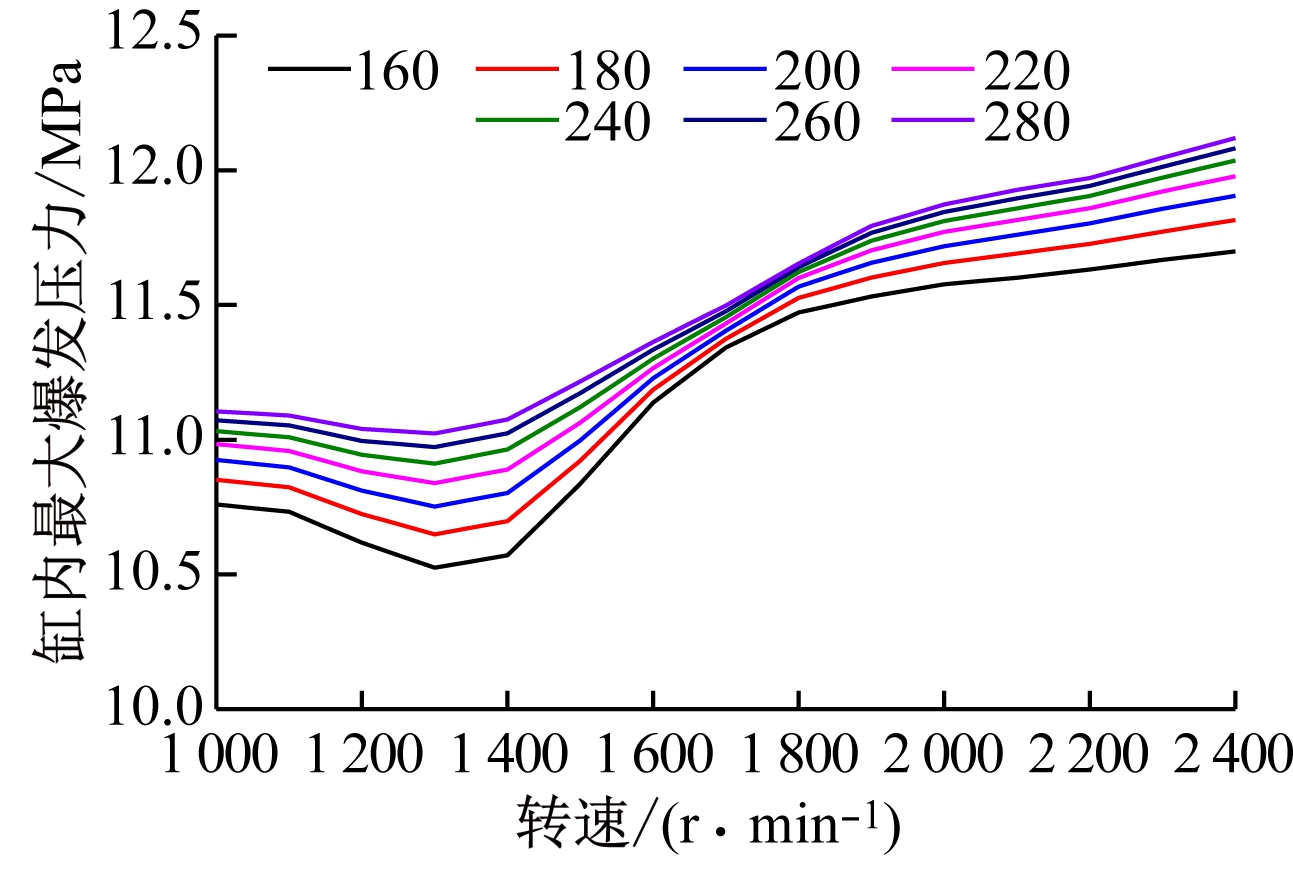

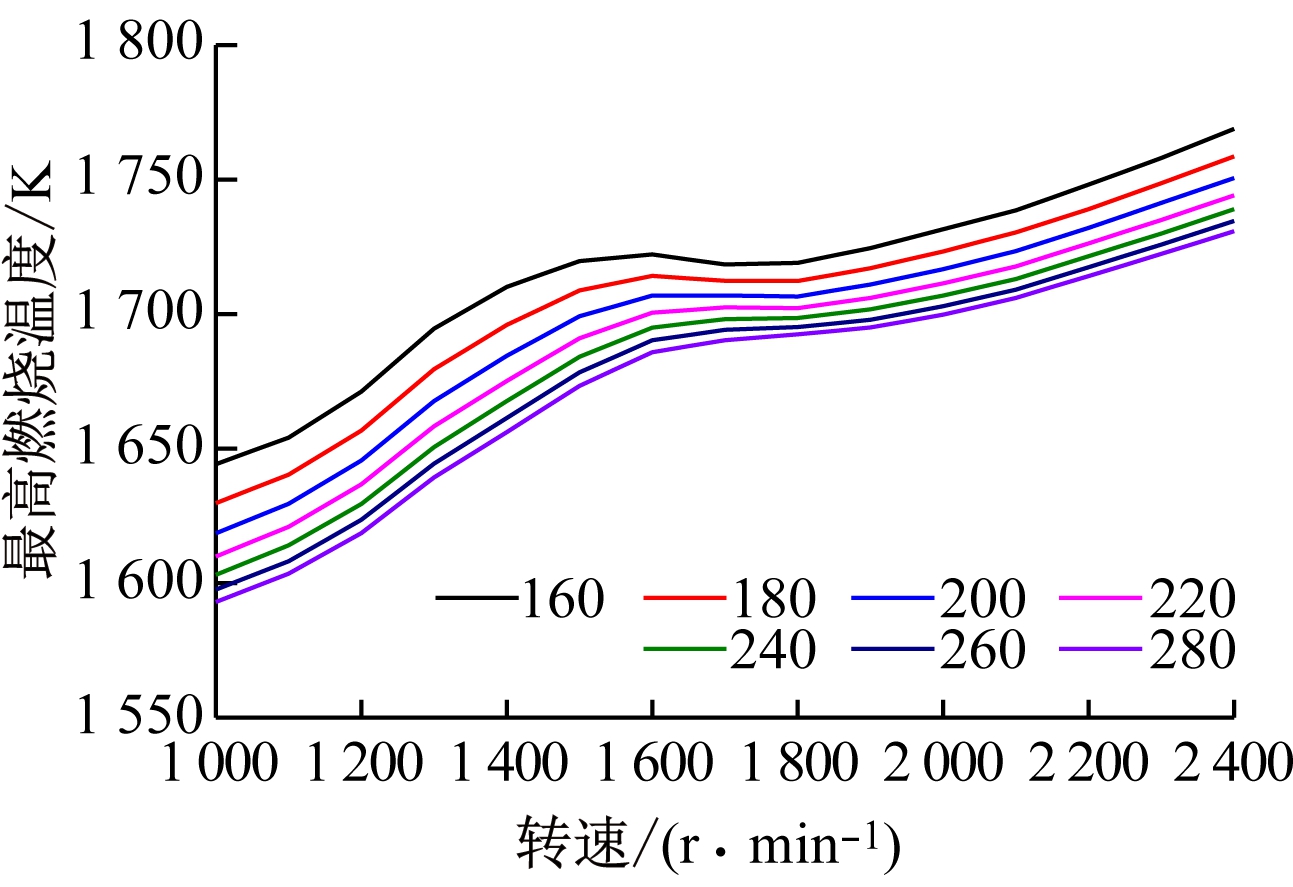

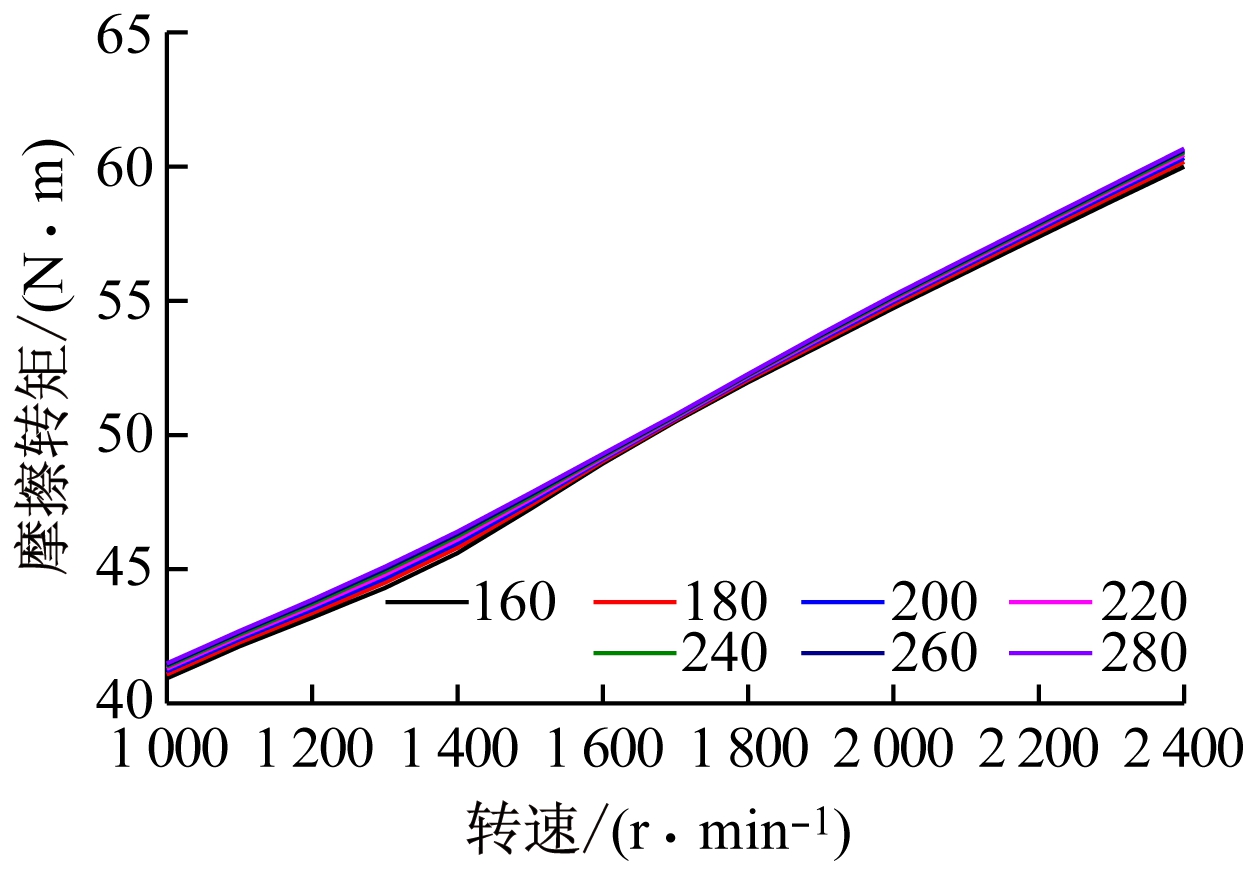

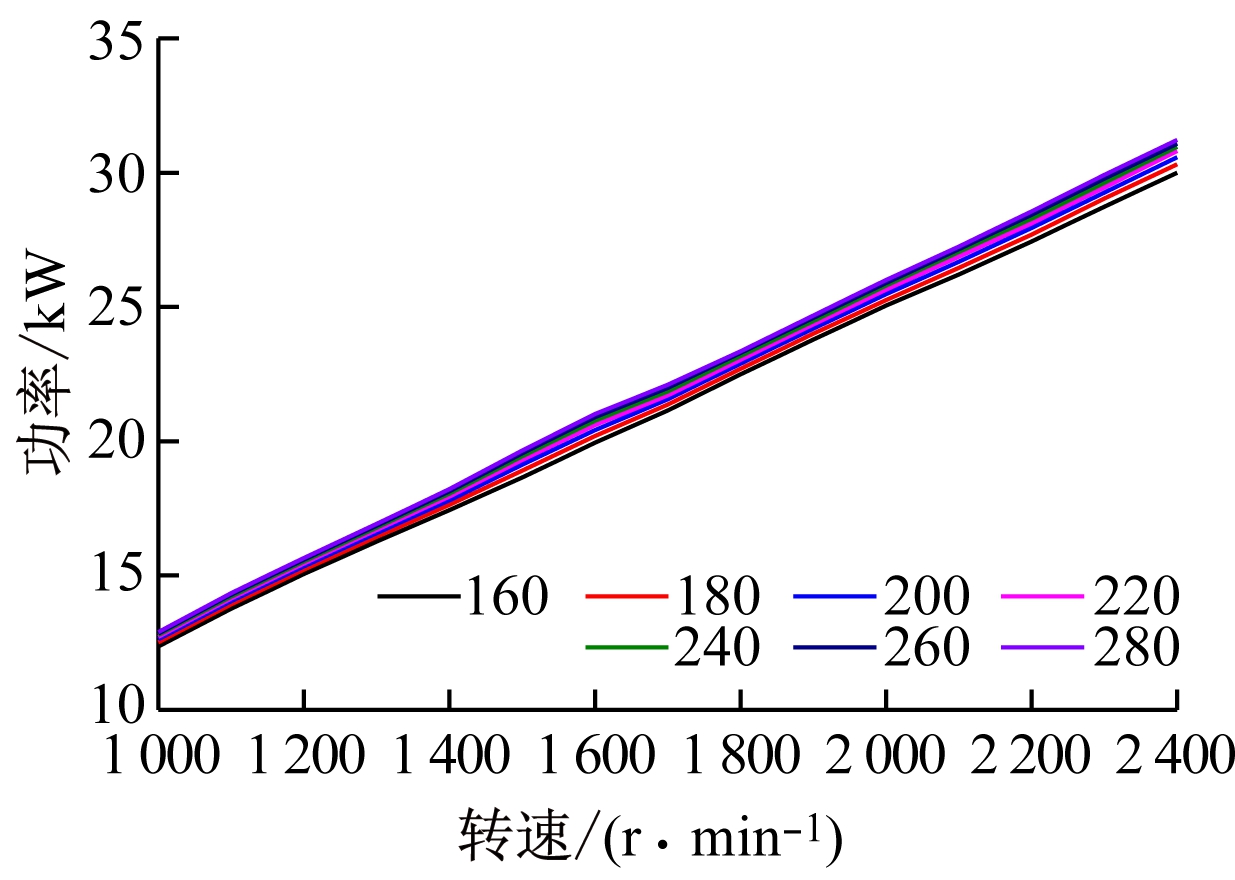

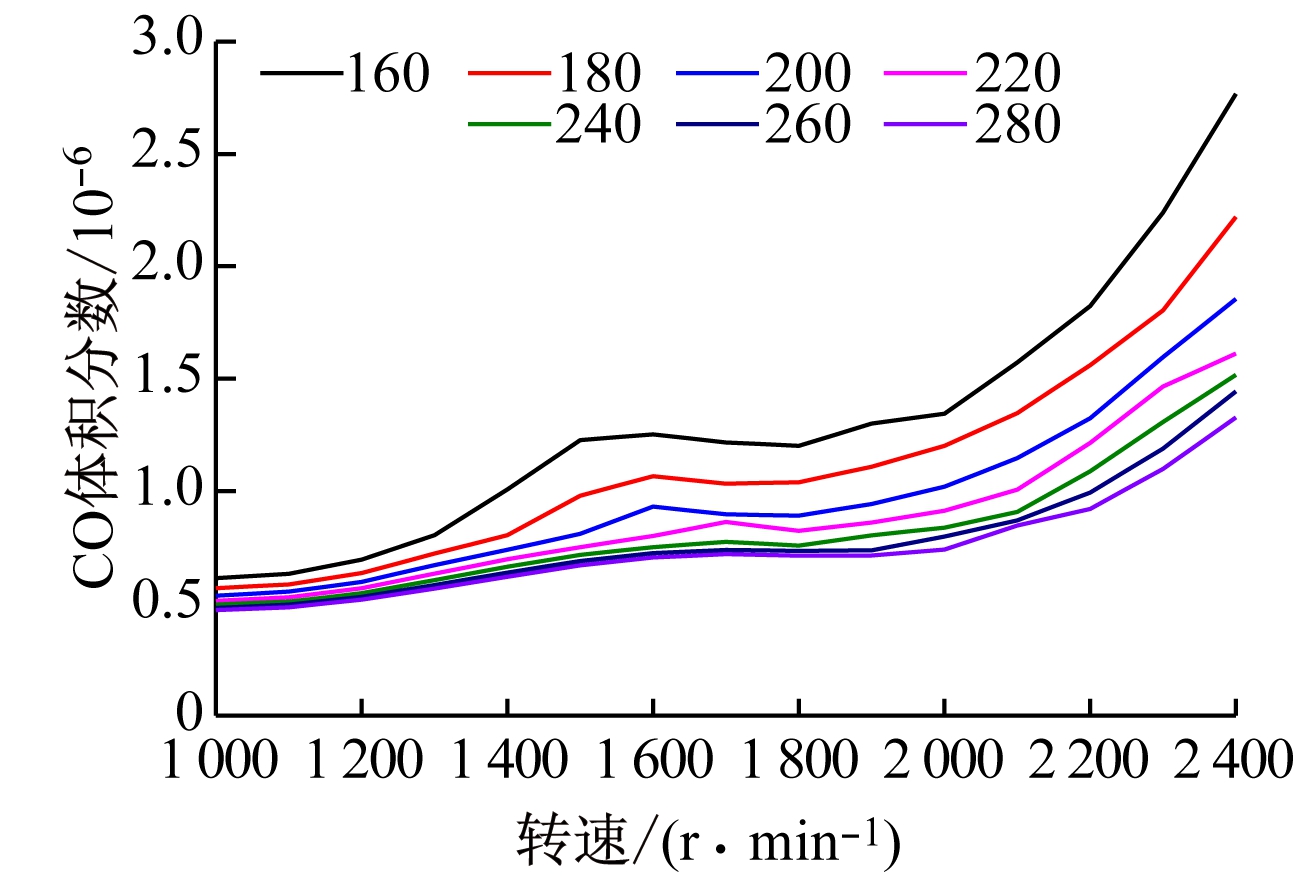

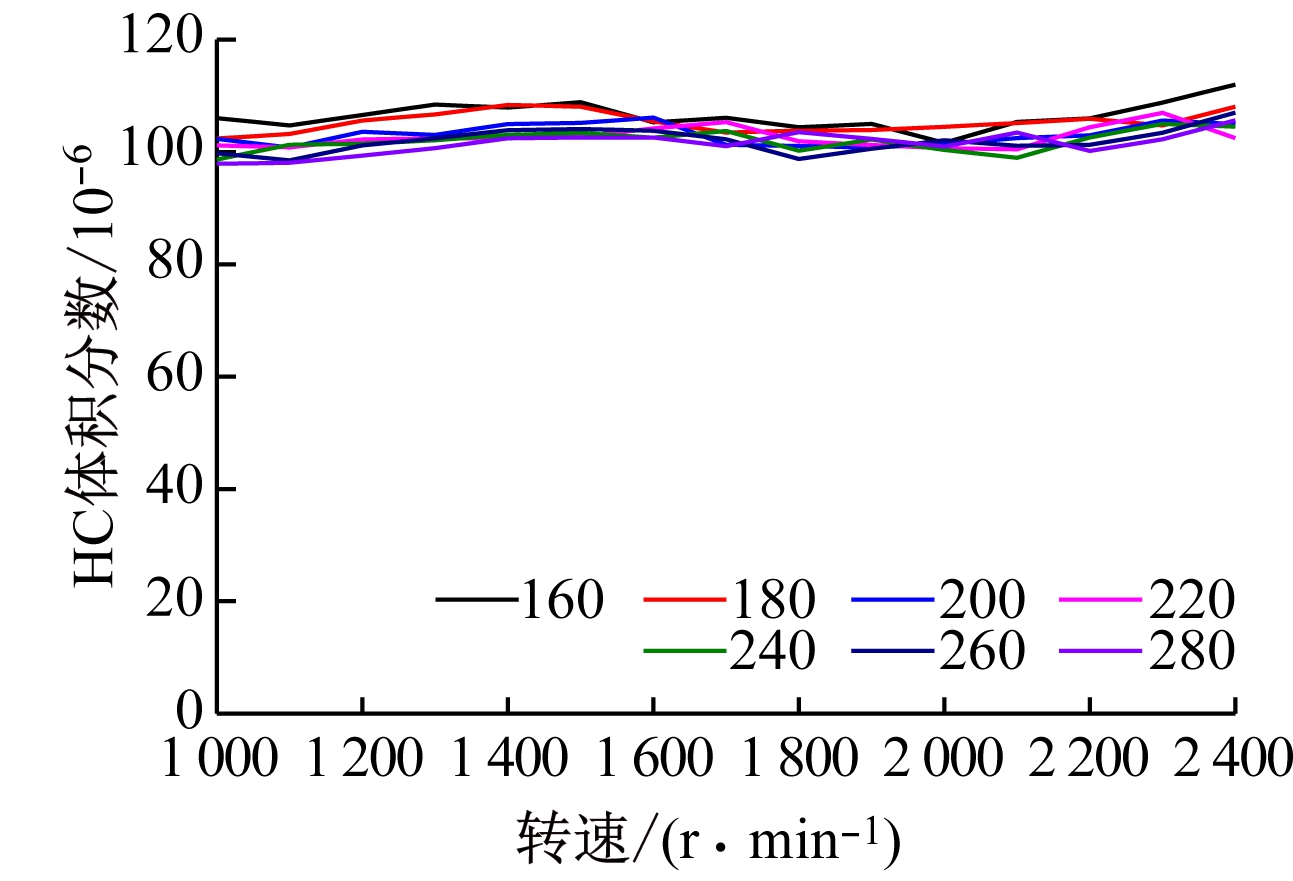

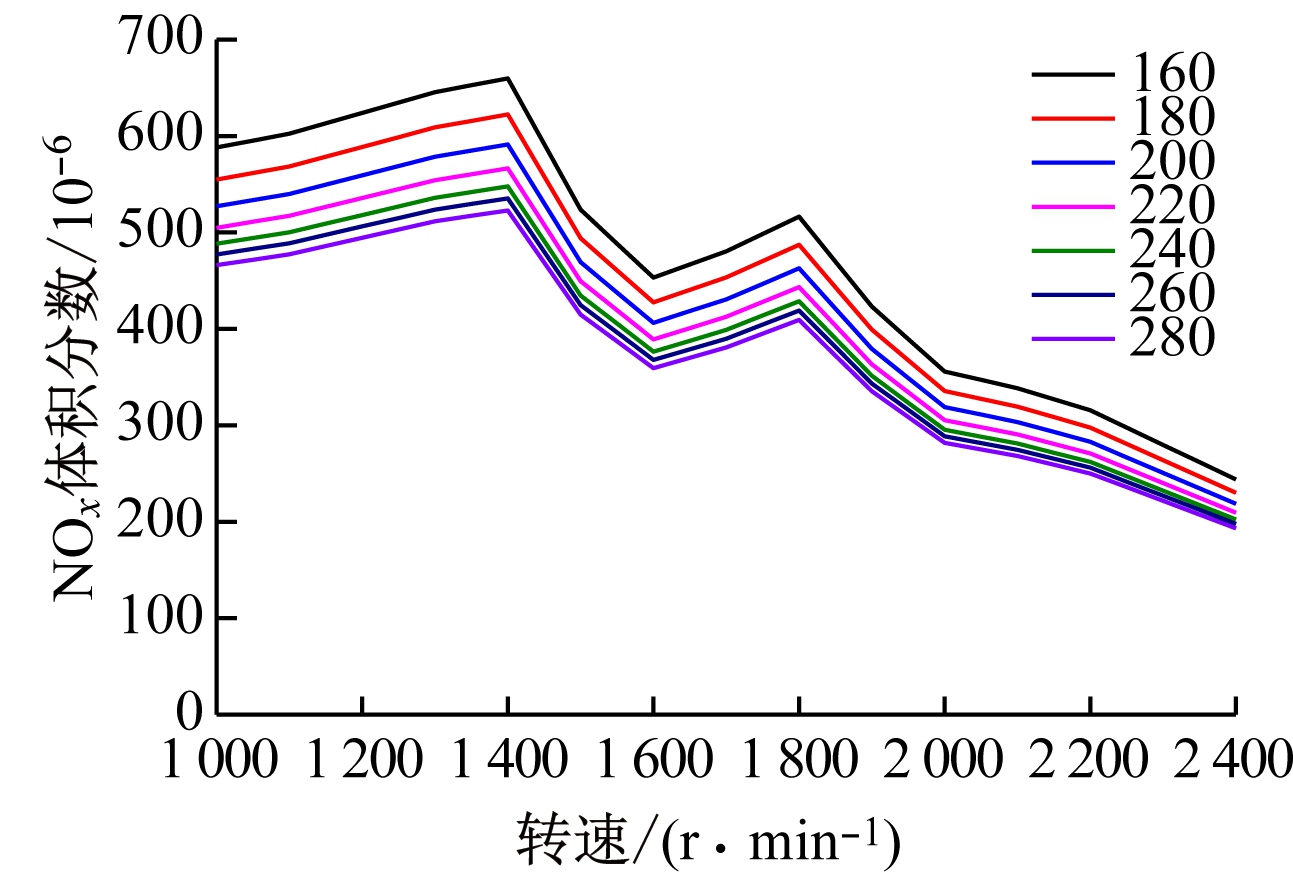

从图10(a)可看出,相同转速下,缸内最大爆发压力随着喷油提前角增大而增大,喷油提前角每增加2°CA,缸内最大爆发压力增加4.5~5.5 MPa。原因是随着喷油提前角增大,滞燃期变长,在滞燃期喷入燃烧室的燃料增多,当着火时,不同气体在急燃期几乎同时燃烧,使缸内最大爆发压力增大[18-19]。从图10(b)可看出,喷油提前角增大会使最高燃烧温度增加。从图10(c)可看出,摩擦转矩随喷油提前角增大而增大,喷油提前角每增加2°CA,摩擦转矩增加0.5~1.5 N·m。从图10(d)可看出,喷油提前角增大对功率的影响较小。从图10(e)可看出,CO体积分数随喷油提前角增大而减小;当喷油提前角为19~25°CA时,CO体积分数随转速的变化幅度较小;当喷油提前角小于17°CA时,CO体积分数随转速的变化幅度较大。从图10(f)可看出,随着喷油提前角增大,HC体积分数减小,但增大喷油提前角对HC体积分数的影响越来越小。从图10(g)可看出,NOx体积分数随喷油提前角增大而增大。综合考虑,在保证防爆柴油机各参数变化在一定范围内且尾气排放较少的情况下,认为在转速变化时间为15 s、转矩为120 N·m的恒转矩变转速工况下,防爆柴油机喷油提前角设置为19°CA较合适。

4.2 进排气防爆阻火器栅栏数量优化

根据流体力学原理,气体流动阻力与气体流速的平方成正比,而加装进排气防爆阻火器后,进排气气体同时受到管道壁面和防爆阻火器栅栏产生的摩擦阻力[20],因此防爆改造后进排气阻力大大增加,在转速变化过程中气体流速不断变化,进排气阻力也在不断变化。以直圆管代替进排气防爆阻火器栅栏(直圆管数量表示进排气防爆阻火器栅栏数量),模拟进排气防爆阻火器对柴油机进排气的影响。仿真设置直圆管数量为160~280个,取值间隔为20个,增大直圆管数量主要目的是降低直圆管中气体流速,进而减小进排气阻力。在转速变化时间为15 s、转矩为120 N·m的恒转矩变转速工况下,不同进排气防爆阻火器栅栏数量下防爆柴油机主要参数变化如图11所示。

(a) 缸内最大爆发压力

(b) 最高燃烧温度

(c) 摩擦转矩

(d) 功率

(e) CO体积分数

(f) HC体积分数

(g) NOx体积分数

图11 不同进排气防爆阻火器栅栏数量下防爆柴油机主要参数变化曲线

Fig.11 Variation curves of main parameters of explosion-proof diesel engine under different number of inlet and exhaust explosion-proof flame arrester fences

从图11(a)可看出,缸内最大爆发压力随进排气防爆阻火器栅栏数量增多而增大,但增大幅度越来越小。从图11(b)可看出,最高燃烧温度随进排气防爆阻火器栅栏数量增多而减小,但减小幅度越来越小。从图11(c)、图11(d)可看出,进排气防爆阻火器栅栏数量对摩擦转矩与功率的影响几乎可以忽略不计。从图11(e)—图11(g)可看出,进排气防爆阻火器栅栏数量增多对尾气排放浓度均有一定的抑制作用,原因可能是随着进排气防爆阻火器栅栏数量增多,排气受阻,尾气在净化机构内停留时间增长。综合考虑,在保证防爆柴油机各参数变化在一定范围内且尾气排放较少的情况下,认为在转速变化时间为15 s、转矩为120 N·m的恒转矩变转速工况下,防爆柴油机进排气防爆阻火器栅栏数量设置为260个较合适。

5 结论

(1) 恒转速变转矩瞬态工况下,与防爆改造前柴油机相比,防爆柴油机空燃比下降更快,缸内最大爆发压力降低,转矩迟滞现象更明显,且转矩升高越快,迟滞效应越严重。恒转矩变转速瞬态工况下,防爆柴油机空燃比随着转速增大而减小,但小负荷增转速过程对空燃比的影响较小。

(2) 缸内最大爆发压力、最高燃烧温度、摩擦转矩和功率均随喷油提前角增大而增大,CO和HC体积分数随喷油提前角增大而减小,NOx体积分数随喷油提前角增大而增大。喷油提前角增大可提高防爆柴油机动力性能,但考虑到尾气排放,不能一味增大喷油提前角。因此,在转速变化时间为15 s、转矩为120 N·m的恒转矩变转速工况下,防爆柴油机喷油提前角设置为19°CA较合适。

(3) 随着进排气防爆阻火器栅栏数量增多,防爆柴油机缸内最大爆发压力增大、最高燃烧温度减小,进排气防爆阻火器栅栏数量增多对防爆柴油机摩擦转矩和功率的影响几乎可以忽略不计,但对尾气排放浓度有一定的抑制作用。因此,在转速变化时间为15 s、转矩为120 N·m的恒转矩变转速工况下,防爆柴油机进排气防爆阻火器栅栏数量设置为260个较合适。

[1] 葛世荣,鲍久圣,曹国华.采矿运输技术与装备[M].北京:煤炭工业出版社,2015.

GE Shirong,BAO Jiusheng,CAO Guohua.Transportation and hoisting technology and equipments in mining[M].Beijing:China Coal Industry Publishing House,2015.

[2] 王烁.煤矿用无轨胶轮车发展现状与展望[J].煤炭与化工,2016,39(5):22-24.

WANG Shuo.Development and outlook of mine trackless tyred vehicle[J].Coal and Chemical Industry,2016,39(5):22-24.

[3] 张良良.小型挖掘机用柴油机瞬态工况模拟及排放性能改进[D].天津:天津大学,2013.

ZHANG Liangliang.Transient simulation and emission performance improvements of diesel engine using in small excavator[D].Tianjin:Tianjin University,2013.

[4] 隋菱歌.增压柴油机瞬态工况性能仿真及优化[D].长春:吉林大学,2012:93-109.

SUI Lingge.Simulation and optimization of turbo-charged diesel engine performance under transient operations[D].Changchun:Jilin University,2012:93-109.

[5] NILSSON T,FROBERG A,ASLUND J.Optimal operation of a turbocharged diesel engine during transients[J].SAE International Journal of Engines,2012,5(2):571-578.

[6] WILLIAM G,DAVID H,FOSTER D E,et al.Analysis of deviations from steady state performance during transient operation of a light duty diesel engine[J].Cryogenics,2012,5(3):909-922.

[7] 王敏,杨蓉,叶洲,等.商用车用电控柴油机增转矩工况的燃烧特性分析[J].内燃机工程,2020,41(5):23-31.

WANG Min,YANG Rong,YE Zhou,et al.Research on combustion characteristics of electronically controlled diesel engine for commercial vehicles at torque-increasing condition[J].Chinese Internal Combustion Engine Engineering,2020,41(5):23-31.

[8] 张龙平,刘忠长,田径,等.车用柴油机瞬态工况试验及性能评价方法[J].哈尔滨工程大学学报,2014,35(4):463-468.

ZHANG Longping,LIU Zhongchang,TIAN Jing,et al.Experiment and performance evaluation methods for automotive diesel engines under transient operation conditions[J].Journal of Harbin Engineering University,2014,35(4):463-468.

[9] 国家安全生产监督管理总局,国家煤矿安全监察局.煤矿安全规程(2016)[M].北京:煤炭工业出版社,2016.

State Administration of Work Safety,State Administration of Coal Mine Safety.Coal mine safety regulations(2016)[M].Beijing:China Coal Industry Publishing House,2016.

[10] 刘海军,侯献军.进/排气边界对高原柴油机缸内制动的数值模拟[J].内燃机学报,2021,39(5):409-416.

LIU Haijun,HOU Xianjun.Numerical simulation of the effect of intake and exhaust boundary on the in-cylinder braking of a plateau diesel engine[J].Transactions of CSICE,2021,39(5):409-416.

[11] 孙丹丹,王铁,张瑞亮,等.加装防爆组件对防爆柴油机性能的影响[J].科学技术与工程,2016,16(20):175-179.

SUN Dandan,WANG Tie,ZHANG Ruiliang,et al.Effect of the explosion-proof components on flameproof diesel engine performance[J].Science Technology and Engineering,2016,16(20):175-179.

[12] 谭飞,鲍久圣,葛世荣,等.矿用防爆柴油机关键技术研究现状与展望[J].煤炭科学技术,2018,46(9):176-182.

TAN Fei,BAO Jiusheng,GE Shirong,et al.Research status and prospect of key technologies for mine explosion-proof diesel engines[J].Coal Science and Technology,2018,46(9):176-182.

[13] 彭振.矿用防爆柴油机尾气后处理技术研究[D].徐州:中国矿业大学,2021.

PENG Zhen.Study on exhaust aftertreatment technology of mining flameproof diesel engine[D].Xuzhou:China University of Mining and Technology,2021.

[14] 雷基林,王东方,邓晰文,等.稳定和过渡工况下柴油机活塞顶面瞬态热负荷变化规律[J].农业工程学报,2018,34(21):65-73.

LEI Jilin,WANG Dongfang,DENG Xiwen,et al.Transient heat load variation of piston top surface under steady and transition conditions[J].Transactions of the Chinese Society of Agricultural Engineering,2018,34(21):65-73.

[15] 宫唤春.插电式混合动力汽车控制策略与建模[J].机械设计与制造,2021(3):106-109.

GONG Huanchun.Control strategy and modeling of plug-in hybrid electric vehicles[J].Machinery Design & Manufacture,2021(3):106-109.

[16] 隋菱歌,刘忠长,韩永强,等.增压柴油机EGR阶跃工况瞬态响应特性仿真分析[J].燃烧科学与技术,2011,17(4):301-307.

SUI Lingge,LIU Zhongchang,HAN Yongqiang,et al.Simulation analysis of transient response of turbocharged diesel engine under EGR step change operation[J].Journal of Combustion Science and Technology,2011,17(4):301-307.

[17] 马朝臣,王恒军.车用涡轮增压器瞬态响应性测试方法[J].哈尔滨工程大学学报,2020,41(9):1255-1260.

MA Chaochen,WANG Hengjun.A measuring method of transient response ability for turbochargers of internal combustion engine[J].Journal of Harbin Engineering University,2020,41(9):1255-1260.

[18] 王俊,申立中,文奕钧,等.大气压力对小型农用柴油机怠速工况燃烧与排放的影响[J].农业工程学报,2020,36(15):73-79.

WANG Jun,SHEN Lizhong,WEN Yijun,et al.Effects of atmospheric pressure on combustion and emission of a small agricultural diesel engine at idle condition[J].Transactions of the Chinese Society of Agricultural Engineering,2020,36(15):73-79.

[19] 杨海涛,续彦芳,畅志明,等.喷油提前角对柴油机燃烧特性的影响分析[J].内燃机,2017(3):50-53.

YANG Haitao,XU Yanfang,CHANG Zhiming,et al.Influence of diesel fuel injection advance angle on combustion characteristic[J].Internal Combustion Engines,2017(3):50-53.

[20] 梁胜龙,马俊.基于CFD柴油机进气系统防爆栅栏结构优化设计[J].机械设计与制造,2020(9):167-171.

LIANG Shenglong,MA Jun.Structural optimization design of explosion-proof fence in diesel engine intake system based on CFD[J].Machinery Design & Manufacture,2020(9):167-171.