姜子豪, 胡友彪, 琚棋定, 周露, 张淑莹

(安徽理工大学 地球与环境学院,安徽 淮南 232001)

摘要:针对现有基于水化学特征的突水水源判别方法过程繁琐、难以判别单个涌水点、忽略了水化学特征之间的相互关联、计算量大等问题,结合Bayes判别法和可拓判别法,提出了一种基于Bayes-可拓判别法的矿井突水水源判别方法。选取潘二煤矿26组不同含水层水样、4组待判水样,以水样中![]() 含量作为水化学特征指标,建立了水样物元模型,采用可拓判别法求得待判水样与已知水样的关联度;结合Bayes判别法的误判损失和待判水样关于已知水样的密度函数,得出Bayes-可拓解,根据Bayes-可拓解最小值判断突水水样类型。分别采用Piper三线图、可拓判别法、Bayes-可拓判别法判别矿井突水水样类型,结果表明:Piper三线图难以准确判断某一水样类型,可拓判别法存在误判情况,Bayes-可拓判别法能够准确判别突水水样类型。

含量作为水化学特征指标,建立了水样物元模型,采用可拓判别法求得待判水样与已知水样的关联度;结合Bayes判别法的误判损失和待判水样关于已知水样的密度函数,得出Bayes-可拓解,根据Bayes-可拓解最小值判断突水水样类型。分别采用Piper三线图、可拓判别法、Bayes-可拓判别法判别矿井突水水样类型,结果表明:Piper三线图难以准确判断某一水样类型,可拓判别法存在误判情况,Bayes-可拓判别法能够准确判别突水水样类型。

关键词:矿井水害防治;矿井突水;突水水源判别;水化学特征;可拓判别法;Bayes-可拓判别法

矿井水害一直是煤矿安全生产的重大威胁。井田内含水层的水化学特征可反映相应含水层的内在特征,因此众多专家学者围绕含水层水样的水化学特征对突水水源判别方法展开研究。杨建等[1]通过研究溶解性有机质在不同含水层之间的运移规律,提出了一种有机-无机联合矿井突水水源判别方法,可实现水源快速识别,但该方法实际操作难度较大。毛志勇等[2]提出了一种基于核主成分分析-改进粒子群算法-极限学习机的矿井突水水源判别模型,可很好地对数据进行优化,从而实现准确识别,但识别过程较为繁琐。曲兴玥等[3]、琚棋定等[4]分别采用Matlab因子分析及距离判别模型和主成分分析-Bayes判别法识别不同矿井的突水水源,但Matlab因子分析及距离判别模型使用的最小二乘法在计算因子得分时会出现失效情况,主成分分析过程中同时存在正负因子时数据评价意义不明确。牟林[5]通过水质动态曲线对干河矿2-112工作面突水水源进行判别,但其为一种趋势判断,对单个涌水点的判别存在难度。其他根据矿井水样的水化学特征进行突水水源判别的方法还有Fisher判别法、可拓判别法、BP神经网络、灰色关联度等[6-14]。上述方法均存在缺陷,如:Fisher判别法无法解决线性不可分问题;可拓判别法忽略了水化学特征之间的相互关联;BP神经网络计算量大,不易操作;灰色关联度判别过程过于主观,难以确定部分最优解。

本文将Bayes判别法和可拓判别法结合,提出了一种基于Bayes-可拓判别法的矿井突水水源判别方法,并以淮南矿业(集团)有限责任公司潘二煤矿为例,介绍了该方法的应用过程,通过与Piper三线图、可拓判别法对比,验证了本文方法能够准确判别矿井突水水样类型。

潘二煤矿位于淮南煤田中部,断层较为发育。矿井水文地质条件较复杂,充水含水层主要为新生界含水层、煤系砂岩含水层、太灰含水层及奥灰含水层。

新生界含水层厚度为195.7~315.0 m,总体呈东南薄、西北厚趋势。受大气降水和地表河流补给,水位随季节变化明显,属潜水-半承压水性质,富水性弱-中等。单位涌水量为0.978~1.740 L/(s·m),渗透系数为6.219~8.427 m/d。

煤系砂岩含水层岩性以中细砂岩、粗砂岩和石英砂岩为主,岩层厚度变化较大。裂隙发育不均导致煤系富水性差异较大。该层富水性总体很弱,主要以静储量为主。抽水试验结果表明,该层静止水位为19.67~24.82 m,单位涌水量为6.320×10-4~0.049 L/(s·m),渗透系数为0.002~0.175 m/d,矿化度为2.187~2.504 g/L。

太灰含水层岩性以灰岩、泥岩和砂质泥岩为主,地层平均厚度为120~139 m。太灰含水层划分为C3-Ⅰ,C3-Ⅱ,C3-Ⅲ3组,每组含4~6层灰岩。3组含水层均在西风井厂内布置1个太灰水文观测孔。依据3个观测孔抽水试验资料,太灰含水层单位涌水量为0.021 L/(s·m),富水性较弱,矿化度为2.645 g/L。

奥灰含水层揭露厚度为22.42~152.67 m,主要岩性为灰岩和白云质灰岩。依据矿井目前奥灰水文观测孔资料,该层单位涌水量为0.5 L/(s·m),富水性中等,渗透系数为0.053~0.744 m/d,矿化度为2.85 g/L。

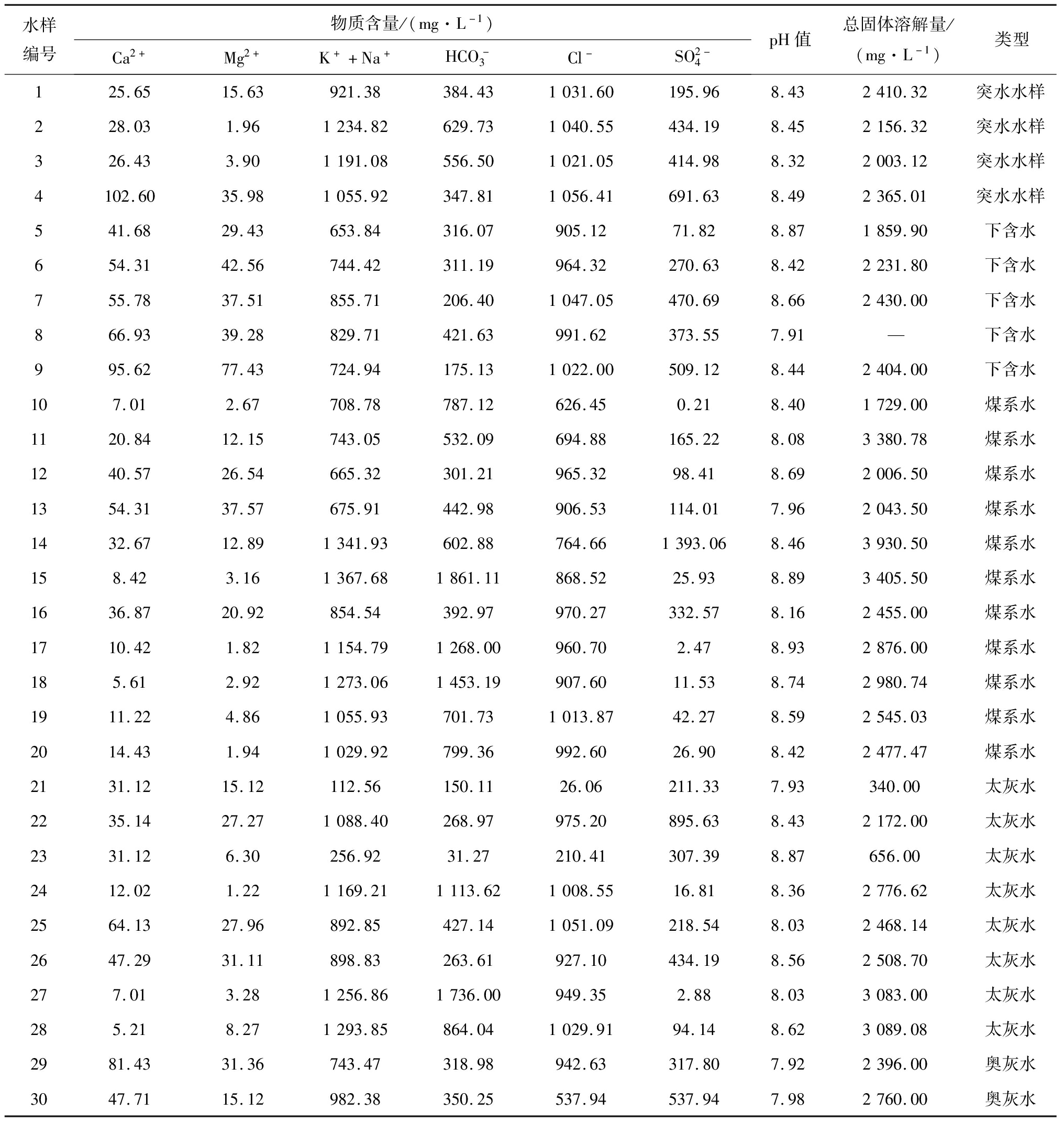

通过对潘二煤矿多次勘察及取样分析,获取30组地下水水样,包括4组突水水样、5组新生界含水层水样(下含水)、11组煤系砂岩含水层水样(煤系水)、8组太灰含水层水样(太灰水)、2组奥灰含水层水样(奥灰水)。地下水水化学特征见表1。

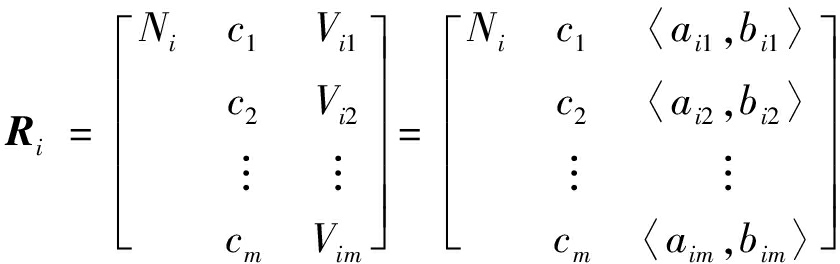

建立已知水样物元模型:

(1)

式中:Ni(i=1,2,…,n,n为总体数,即水样类型数)为第i个总体;cj(j=1,2,…,m,m为水化学特征数)为Ni的水化学特征,本文指水样的特征离子![]() 为Ni关于特征cj所规定的经典域,即cj含量区间;aij为Vij下限;bij为Vij上限。

为Ni关于特征cj所规定的经典域,即cj含量区间;aij为Vij下限;bij为Vij上限。

表1 潘二煤矿地下水水化学特征

Table 1 Hydrochemical characteristics of underground water in Pan'er Coal Mine

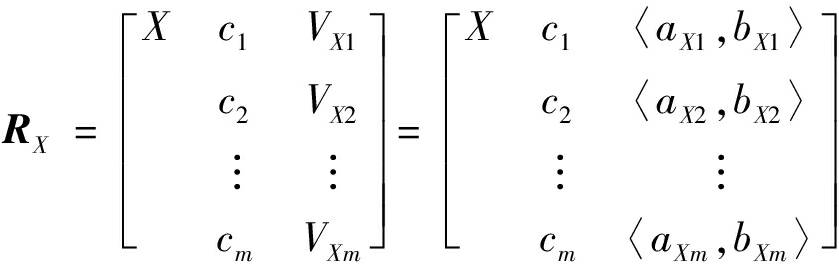

建立待判水样X的节域物元模型:

(2)

式中:VXj为待判水样水化学特征cj含量区间;aXj为VXj下限;bXj为VXj上限。

计算待判水样归属于某一类型的程度,即关联度:

(3)

式中:vXj为待判水样水化学特征cj含量;ρ(vXj,Vij)为vXj到Vij的距;ρ(vXj,VXj)为vXj到VXj的距。

(4)

(5)

待判水样X关于总体Ni的关联度为

![]()

(6)

式中αij为水化学特征cj的权系数,0≤αij≤1。

可拓判别法根据关联度Ki(X)判断水样类型,即待判水样来自与其关联度最大的总体。

Bayes-可拓判别法基于Bayes判别法和可拓判别法发展而来,其结合Bayes判别解和可拓判别法得到的关联度,克服了Bayes判别法没有考虑样品各指标对样品总体的影响、可拓判别法忽略判别过程中可能产生的误判损失及总体出现的先验概率和分布等缺点。

Bayes判别法需要考虑误判损失C(j|i)及待判水样X关于总体Ni的密度函数fi(X)。

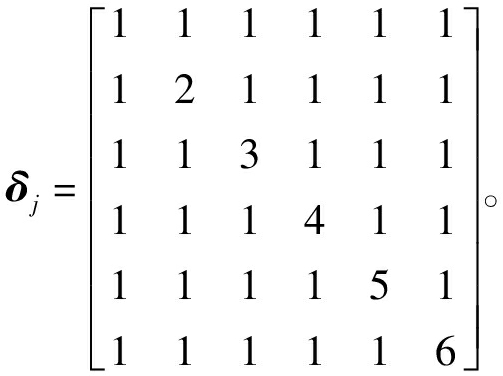

(7)

式中:δj为待判水样X水化学特征cj含量的协方差矩阵;μX为待判水样X水化学特征cj含量的均值向量;μij为已知水样水化学特征cj含量的均值向量。

结合Bayes判别法,Bayes-可拓解为

![]()

(8)

式中qi为先验概率,一般情况下![]()

Bayes-可拓判别法根据Bayes-可拓解hj(X)判断水样类型,即待判水样来自可拓解最小的总体。

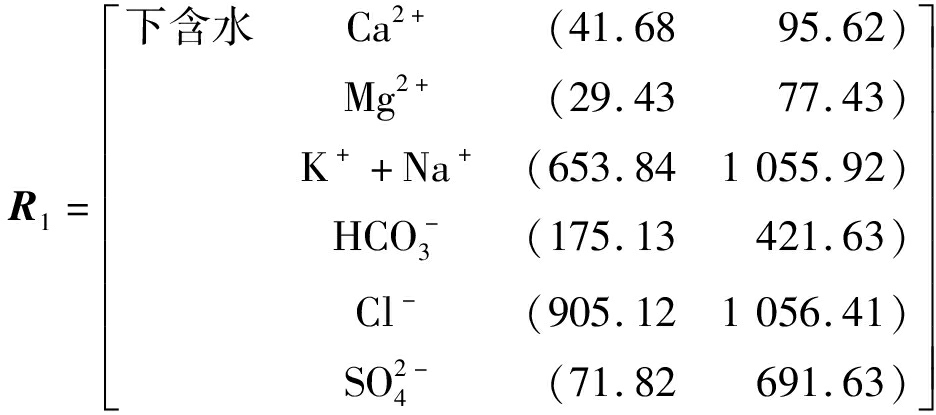

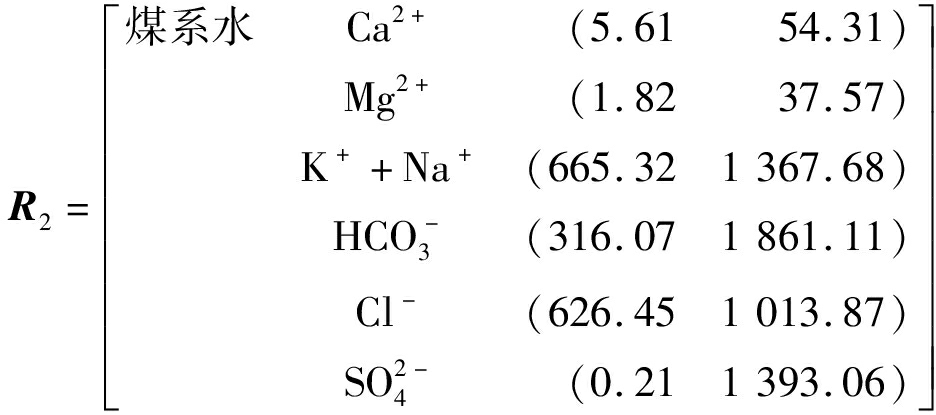

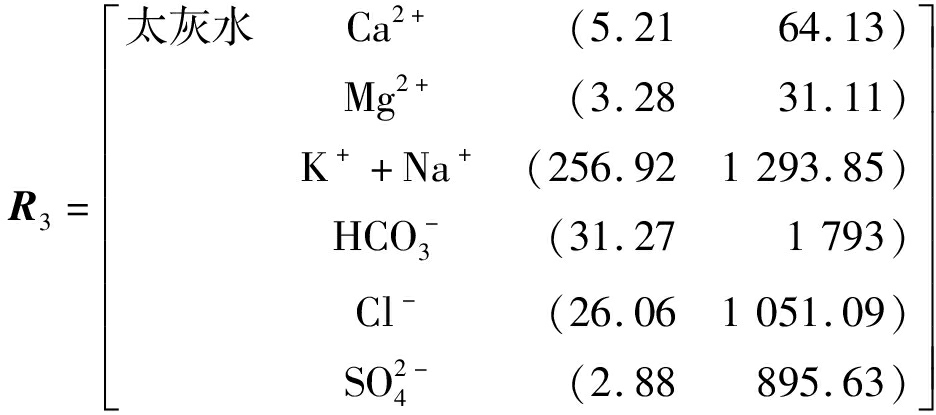

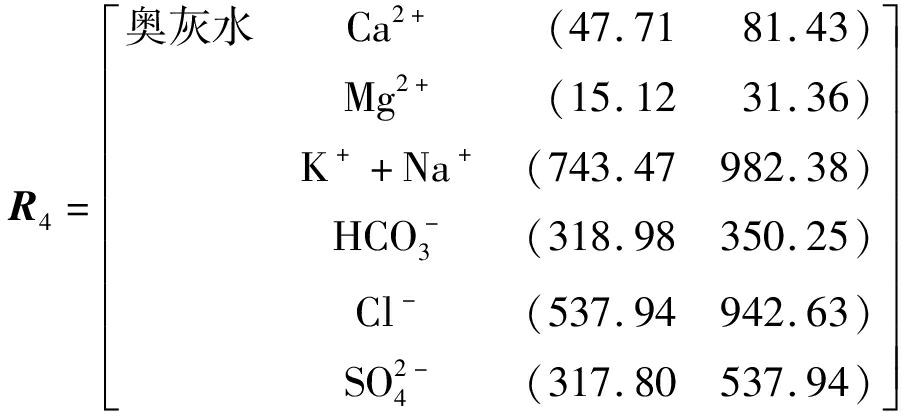

根据表1数据,建立水样物元模型Ri=[含水层 判别特征 含量区间]。含水层分别为下含水、煤系水、太灰水及奥灰水,分别对应i=1,2,3,4;特征指标选取![]() 含量区间以表1中除4组突水水样外各特征离子含量的最大值、最小值作为上下限。由此可得已知水样物元模型:

含量区间以表1中除4组突水水样外各特征离子含量的最大值、最小值作为上下限。由此可得已知水样物元模型:

依据可拓判别法计算4组突水水样与R1,R2,R3,R4的关联度,并依据Bayes-可拓判别法计算Bayes-可拓解。计算过程中权系数![]() 先验概率

先验概率![]() 为六元正态矩阵,

为六元正态矩阵,

分别采用Piper三线图、可拓判别法和Bayes-可拓判别法对突水水样进行分析。

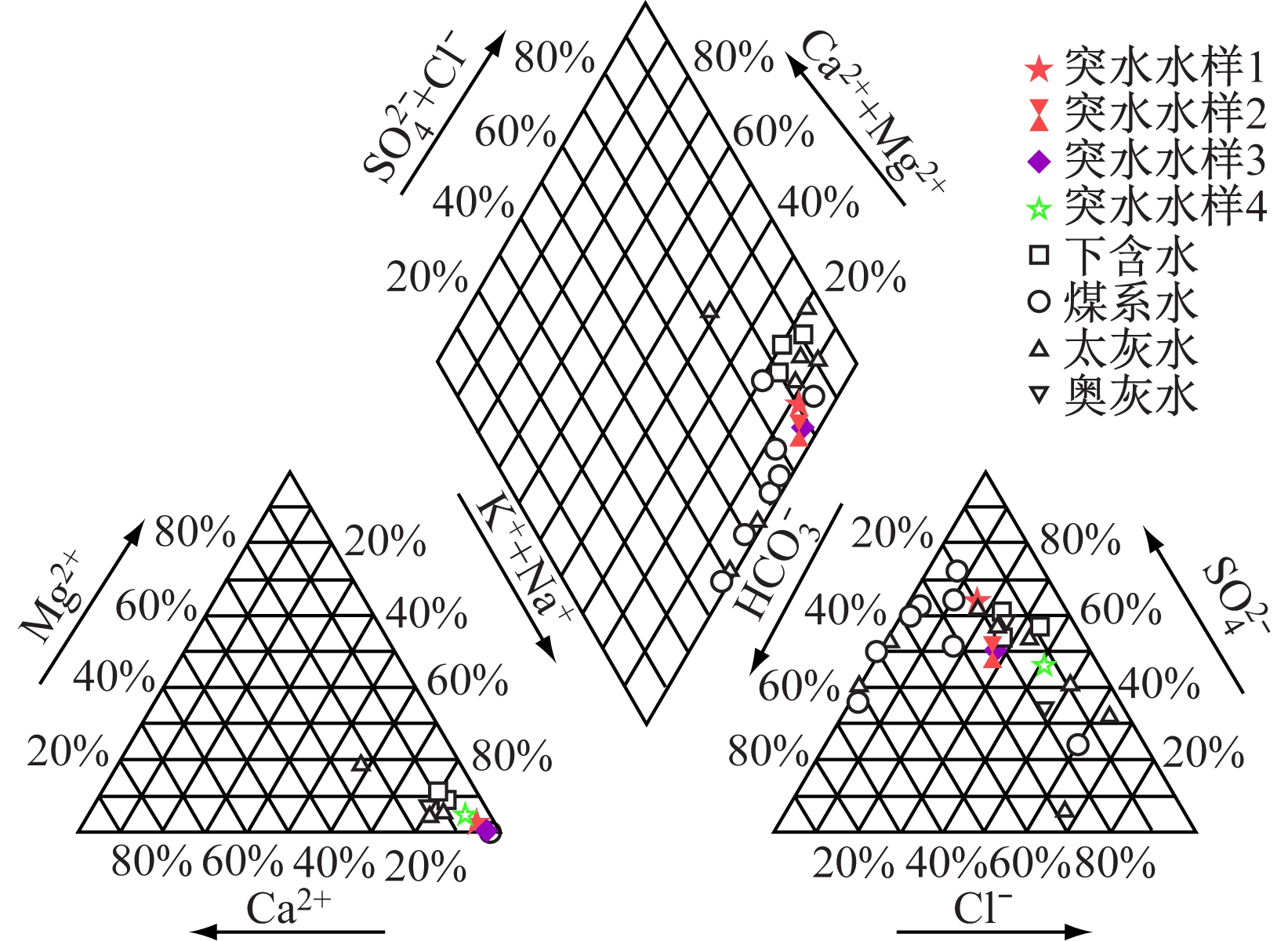

根据表1数据,采用AqQA软件绘制Piper三线图,如图1所示。通过水样的落点位置分析水样来源及各含水层的水化学特征。

图1 潘二煤矿水样水化学特征Piper三线图

Fig.1 Piper trilinear diagram of hydrochemical characteristics of water samples in Pan'er Coal Mine

从图1可看出:下含水水化学类型主要为![]() 型,煤系水水化学类型为

型,煤系水水化学类型为![]() 型和

型和![]() 型,说明煤系砂岩含水层的充水水源可能来自新生界含水层;太灰水水化学类型为

型,说明煤系砂岩含水层的充水水源可能来自新生界含水层;太灰水水化学类型为![]() 型,说明太灰含水层与煤系砂岩含水层存在一定的水力联系;奥灰水水化学类型主要为

型,说明太灰含水层与煤系砂岩含水层存在一定的水力联系;奥灰水水化学类型主要为![]() 型;突水水样1,2,3的水化学类型为

型;突水水样1,2,3的水化学类型为![]() 型,突水水样4的水化学类型为

型,突水水样4的水化学类型为![]() 型。

型。

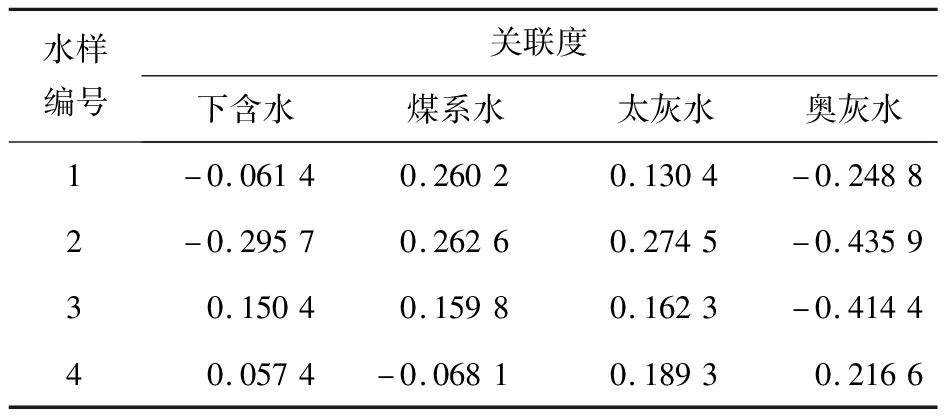

根据表1数据并结合式(1)—式(6),计算可拓判别关联度,结果见表2。根据表2判别突水水样1为煤系水,突水水样2,3为太灰水,突水水样4为奥灰水。

表2 可拓判别法计算结果

Table 2 Calculation results of extension discrimination method

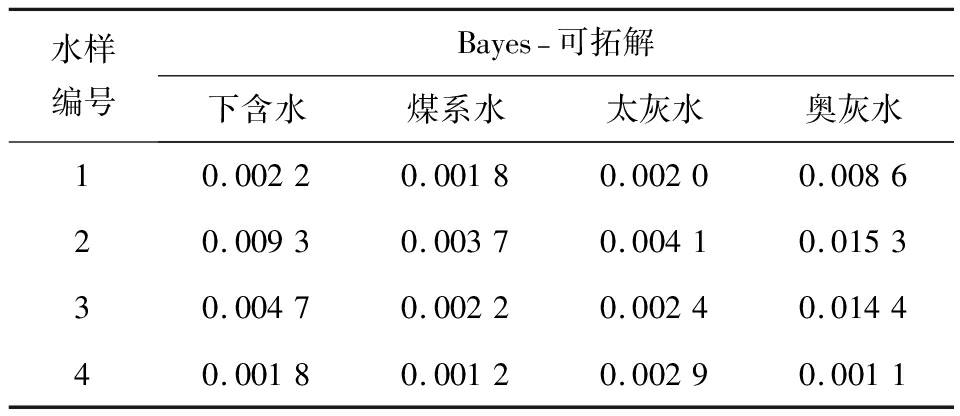

根据表1数据并结合式(1)—式(8),计算Bayes-可拓解,结果见表3。根据表3判别突水水样1,2,3为煤系水,突水水样4为奥灰水。

表3 Bayes-可拓判别法计算结果

Table 3 Calculation results of Bayes-extension discrimination method

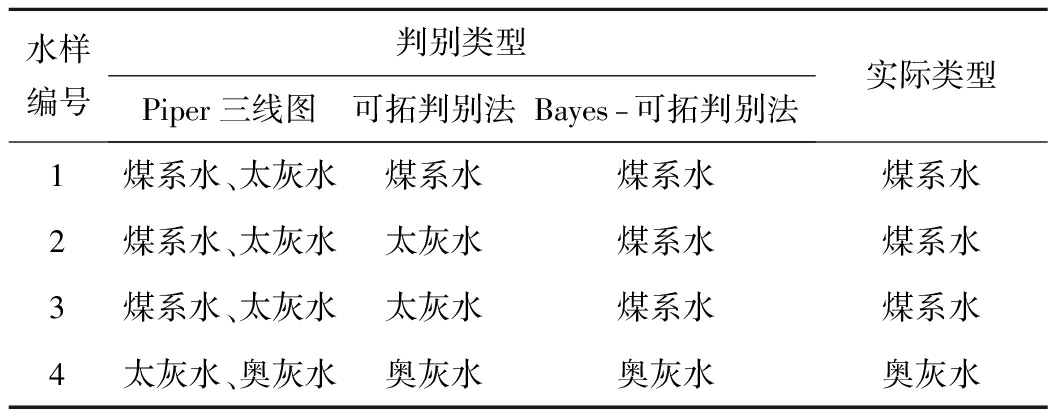

3种方法判别结果对比见表4。

表4 3种方法判别结果对比

Table 4 Discrimination results comparison of three methods

从表4可看出,采用Piper三线图很难对某一突水水样做出准确判断;以关联度为判别依据的可拓判别法对突水水样2,3作出了误判;Bayes-可拓判别法对突水水样的判别结果与实际类型一致,未出现误判,证明该方法可准确判别矿井突水水源。

(1)实际矿井地质条件复杂,且各含水层之间存在不同程度的水力联系,易导致突水水源误判情况。进行突水水源判别时,必须考虑误判损失。Bayes-可拓判别法结合了Bayes判别法和可拓判别法的优势,避免了Bayes判别法中各特征指标对总体样本的影响及可拓判别法忽视误判损失带来的判别误差问题,可有效提高水源判别精度。

(2)选取潘二煤矿各含水层30组水样,根据各水样的水化学特征,分别采用Piper三线图、可拓判别法、Bayes-可拓判别法判别突水水样类型,结果表明采用Piper三线图判别突水水源时难以准确判断某一水样类型,可拓判别法存在误判情况,Bayes-可拓判别法能够准确判别突水水样类型。

参考文献(References):

[1] 杨建,刘基,靳德武,等.有机-无机联合矿井突水水源判别方法[J].煤炭学报,2018,43(10):2886-2894.

YANG Jian,LIU Ji,JIN Dewu,et al.Method of determining mine water inrush source based on combination of organic-inorganic water chemistry[J].Journal of China Coal Society,2018,43(10):2886-2894.

[2] 毛志勇,黄春娟,路世昌,等.基于KPCA-MPSO-ELM的矿井突水水源判别模型[J].中国安全科学学报,2018,28(8):111-116.

MAO Zhiyong,HUANG Chunjuan,LU Shichang,et al.KPCA-MPSO-ELM based model for discrimination of mine water inrush source[J].China Safety Science Journal,2018,28(8):111-116.

[3] 曲兴玥,施龙青.基于Matlab因子分析及距离判别模型的矿井突水水源识别[J].煤炭科学技术,2018,46(8):178-182.

QU Xingyue,SHI Longqing.Discrimination on mine water inrush source based on Matlab factor analysis and distance distinguished model[J].Coal Science and Technology,2018,46(8):178-182.

[4] 琚棋定,胡友彪,张淑莹.基于主成分分析与贝叶斯判别法的矿井突水水源识别方法研究[J].煤炭工程,2018,50(12):90-94.

JU Qiding,HU Youbiao,ZHANG Shuying.Mine water inrush source identification method based on principal component analysis and Bayesian discriminant[J].Coal Engineering,2018,50(12):90-94.

[5] 牟林.水质动态曲线预测在突水水源判别中的应用[J].煤田地质与勘探,2016,44(3):70-74.

MOU Lin.Application of dynamic curve prediction method in discriminating water-bursting source[J].Coal Geology & Exploration,2016,44(3):70-74.

[6] 董毅,解海军.许疃矿32块段出水水源Fisher识别分析[J].西安科技大学学报,2016,36(1):75-79.

DONG Yi,XIE Haijun.Discrimination analysis of water inrush source by Fisher in Xutuan Mine 32 block[J].Journal of Xi'an University of Science and Technology,2016,36(1):75-79.

[7] 孙福勋,魏久传,万云鹏,等.基于Fisher判别分析和质心距评价法的矿井水源判别[J].煤田地质与勘探,2017,45(1):80-84.

SUN Fuxun,WEI Jiuchuan,WAN Yunpeng,et al.Recognition method of mine water source based on Fisher's discriminant analysis and centroid distance evaluation[J].Coal Geology & Exploration,2017,45(1):80-84.

[8] 郭江峰,姚多喜,黄河.基于Bayes算法的煤矿井下突水水源判识系统的设计与实现[J].水文地质工程地质,2016,43(2):153-158.

GUO Jiangfeng,YAO Duoxi,HUANG He.System design and implementation of water source identification of mine water inrush based on the Bayes algorithm[J].Hydrogeology & Engineering Geology,2016,43(2):153-158.

[9] 张好,姚多喜,鲁海峰,等.主成分分析与Bayes判别法在突水水源判别中的应用[J].煤田地质与勘探,2017,45(5):87-93.

ZHANG Hao,YAO Duoxi,LU Haifeng,et al.Application of principal component analysis and Bayes discrimination approach in water source identification[J].Coal Geology & Exploration,2017,45(5):87-93.

[10] 宋世杰,于师建,令春伟.改进的SOFM神经网络在矿井水源判别中的应用[J].矿业研究与开发,2017,37(12):1-5.

SONG Shijie,YU Shijian,LING Chunwei.Application of water source identification in mine based on the improved SOFM neural network[J].Mining Research and Development,2017,37(12):1-5.

[11] 李垣志,牛国庆,刘慧玲.改进的GA-BP神经网络在矿井突水水源判别中的应用[J].中国安全生产科学技术,2016,12(7):77-81.

LI Yuanzhi,NIU Guoqing,LIU Huiling.Application of improved GA-BP neural network on identification of water inrush source in mine[J].Journal of Safety Science and Technology,2016,12(7):77-81.

[12] 张淑莹,胡友彪,琚棋定.基于水化学特征分析判别朱集矿矿井突水水源[J].矿业安全与环保,2018,45(6):53-56.

ZHANG Shuying,HU Youbiao,JU Qiding.Distinguishing the sources of water inrush in Zhuji Coal Mine by hydrochemical characteristics[J].Mining Safety & Environmental Protection,2018,45(6):53-56.

[13] 张淑莹,胡友彪,邢世平.基于独立性权-灰色关联度理论的突水水源判别[J].水文地质工程地质,2018,45(6):36-41.

ZHANG Shuying,HU Youbiao,XING Shiping.Discrimination of the mine water inrush source based on principal component analyses-theory of gray relational degree[J].Hydrogeology & Engineering Geology,2018,45(6):36-41.

[14] 李垣志,牛国庆,张轩轩.矿井突水水源判别的ESN正则化模型[J].煤田地质与勘探,2018,46(1):108-114.

LI Yuanzhi,NIU Guoqing,ZHANG Xuanxuan.ESN regularization model for discriminating mine water inrush source[J].Coal Geology & Exploration,2018,46(1):108-114.

JIANG Zihao, HU Youbiao, JU Qiding, ZHOU Lu, ZHANG Shuying

(School of Earth and Environment, Anhui University of Science and Technology, Huainan 232001, China)

Abstract:For problems of existing discrimination methods of water inrush source based on hydrochemical characteristics such as complex process, difficulty to distinguish single water inrush point, neglecting the correlation among hydrochemical characteristics, large calculation amount and so on, a discrimination method of mine water inrush source based on Bayes-extension discrimination method was proposed combining with Bayes discrimination method and extension discrimination method.Twenty-six groups of water samples from different aquifers and four groups of water samples to be judged in Pan'er Coal Mine are obtained, the content of![]() Cl-,

Cl-,![]() K++Na+, Mg2+, Ca2+in the water samples is taken as hydrochemical characteristic indexes, and thus matter-element models of the water samples are established.The correlation degrees between the water samples to be judged and the known water samples are obtained by use of extension discriminant method.The miscalculation loss of Bayes discriminant method and density function of the water samples to be judged with the known water samples are combined to get Bayes-extension solutions.The type of water inrush sample is discriminated according to the minimum value of Bayes-extension solutions.Piper trilinear diagram, extension discriminant method and Bayes-extension discriminant method are adopted separately to discriminate the type of mine water inrush samples.The results show that Piper trilinear diagram is difficult to accurately discriminate a certain type of water samples, extension discriminant method has misjudgment, while Bayes-extension discriminant method can accurately discriminate the type of water inrush sample.

K++Na+, Mg2+, Ca2+in the water samples is taken as hydrochemical characteristic indexes, and thus matter-element models of the water samples are established.The correlation degrees between the water samples to be judged and the known water samples are obtained by use of extension discriminant method.The miscalculation loss of Bayes discriminant method and density function of the water samples to be judged with the known water samples are combined to get Bayes-extension solutions.The type of water inrush sample is discriminated according to the minimum value of Bayes-extension solutions.Piper trilinear diagram, extension discriminant method and Bayes-extension discriminant method are adopted separately to discriminate the type of mine water inrush samples.The results show that Piper trilinear diagram is difficult to accurately discriminate a certain type of water samples, extension discriminant method has misjudgment, while Bayes-extension discriminant method can accurately discriminate the type of water inrush sample.

Key words:water hazard prevention; mine water inrush; water inrush source discrimination; hydrochemical characteristic; extension discrimination method; Bayes-extension discrimination method

中图分类号:TD745

文献标志码:A

文章编号:1671-251X(2020)04-0028-06

DOI:10.13272/j.issn.1671-251x.2019070087

收稿日期:2019-07-29;修回日期:2020-02-21;责任编辑:李明。

基金项目:国家重点研发计划项目(2017YFC0804101);国家自然科学基金资助项目(41472235)。

作者简介:姜子豪(1996-),男,安徽黄山人,硕士研究生,研究方向为矿井防治水,E-mail:1255751407@qq.com。

引用格式:姜子豪,胡友彪,琚棋定,等.矿井突水水源判别方法[J].工矿自动化,2020,46(4):28-33.

JIANG Zihao,HU Youbiao,JU Qiding,et al.A discrimination method of mine water inrush source[J].Industry and Mine Automation,2020,46(4):28-33.