Prediction of height adjustment of shearer drum based on improved gated recurrent neural network

-

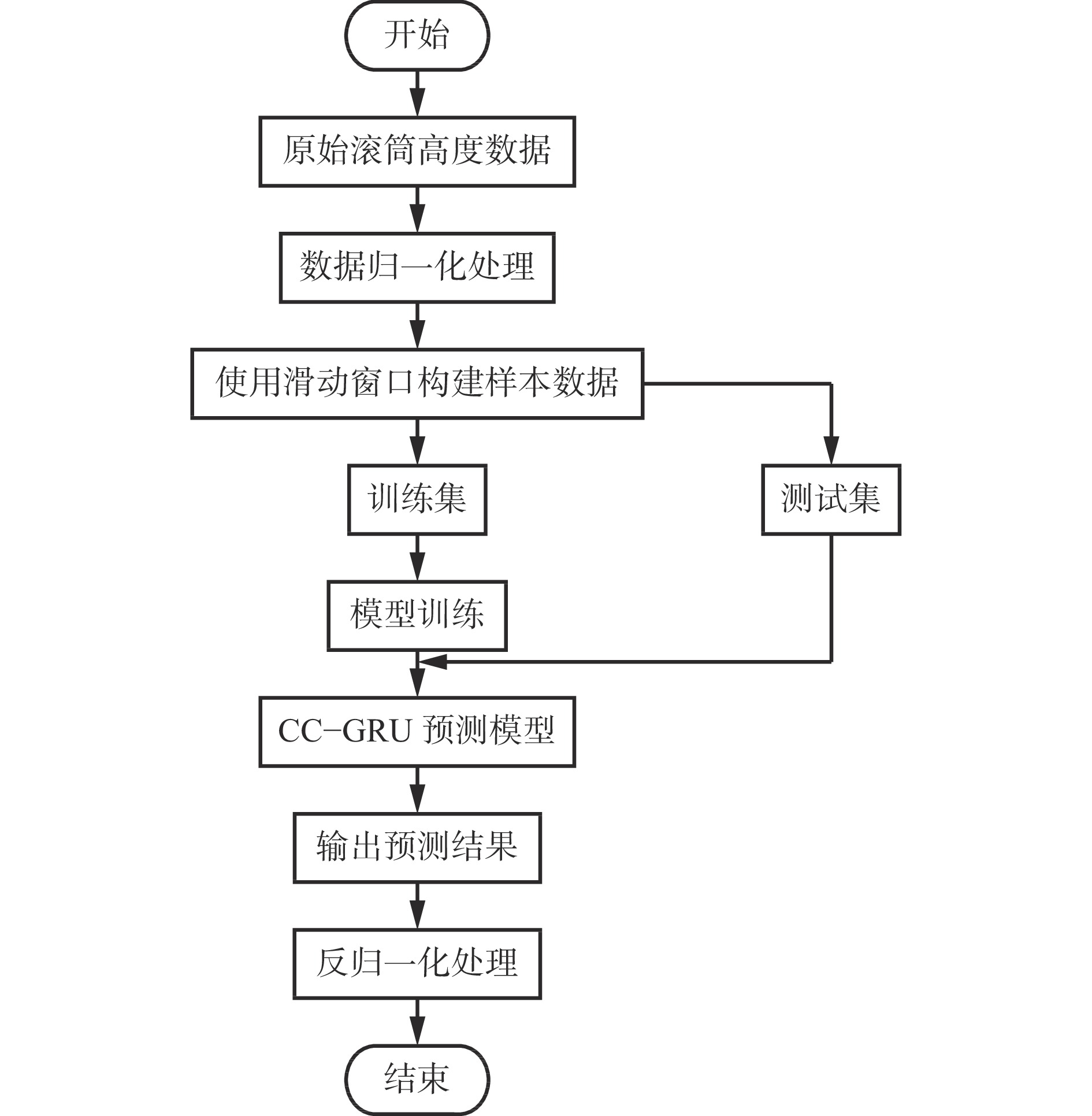

摘要: 采煤机自适应截割技术是实现综采工作面智能化开采的关键技术。针对采煤机在复杂煤层下自动截割精度较低的问题,提出了一种基于改进门控循环神经网络(GRU)的采煤机滚筒调高量预测方法。鉴于截割轨迹纵向及横向相邻数据之间的相关性,采用定长滑动时间窗法对获取的采煤机滚筒高度数据进行预处理,将输入数据划分为连续、大小可调的子序列,同时处理横向、纵向的特征信息。为提高模型预测效率,满足循环截割的实时性要求,提出了一种用因果卷积改进的门控循环神经网络(CC−GRU),对输入数据进行双重特征提取和双重数据过滤。CC−GRU利用因果卷积提前聚焦序列纵向的局部时间特征,以减少计算成本,提高运算速度;利用门控机制对卷积得到的特征进行序列化建模,以捕捉元素之间的长期依赖关系。实验结果表明,采用CC−GRU模型对采煤机滚筒调高量进行预测,平均绝对误差(MAE)为43.80 mm,平均绝对百分比误差(MAPE)为1.90%,均方根误差(RMSE)为50.35 mm,决定系数为0.65,预测时间仅为0.17 s;相比于长短时记忆(LSTM)神经网络、GRU、时域卷积网络(TCN),CC−GRU模型的预测速度较快且预测精度较高,能够更准确地对采煤机调高轨迹进行实时预测,为工作面煤层模型的建立和采煤机调高轨迹的预测提供了依据。Abstract: The adaptive cutting technology of the shearer is a key technology for achieving intelligent mining in fully mechanized working faces. In order to solve the problem of low automatic cutting precision of the shearer in complex coal seams, a prediction method for the height adjustment of shearer drum based on improved gated recurrent neural network (GRU) is proposed. Considering the correlation between adjacent data in the longitudinal and transverse directions of the cutting trajectory, the fixed length sliding time window method is used to obtain the height data of the shearer drum. The input data is divided into continuous and adjustable subsequences, while processing the feature information in the transverse and longitudinal directions. To improve the prediction efficiency of the model and meet the real-time requirements of cyclic cutting, causal convolution gated recurrent unit(CC-GRU) is proposed to perform dual feature extraction and dual data filtering on input data. CC-GRU utilizes causal convolution to focus on the local temporal features in the longitudinal direction of the sequence in advance, in order to reduce computational costs and improve computational speed. CC-GRU uses gating mechanism to serialize and model the features obtained from convolution to capture long-term dependencies between elements. The experimental results show that using the CC-GRU model to predict the height adjustment of the shearer drum, the MAE is 43.80 mm, MAPE is 1.90%, RMSE is 50.35 mm, the determination coefficient is 0.65, and the prediction time is only 0.17 seconds. Compared to long short term memory (LSTM) neural networks, GRU, and temporal convolutional network (TCN), the CC-GRU model has a faster prediction speed and higher prediction precision. It can more accurately predict the height adjustment trajectory of the shearer in real time. This provides a basis for the establishment of coal seam models in the working face and the prediction of the height adjustment trajectory of the shearer.

-

表 1 不同参数下CC−GRU模型的预测结果

Table 1. Prediction results of CC-GRU model under different parameters

隐层层数 隐层节点数 $ {\rm{MAE}}/{\mathrm{mm}} $ $ {\rm{MAPE}}/\text{%} $ $ {\rm{RMSE}}/{\mathrm{mm}} $ $ {{{R^{\text{2}}}}} $ 第1层 第2层 第3层 2 16 16 — 46.54 2.02 53.41 0.61 2 32 16 — 51.88 2.25 64.73 0.35 2 32 32 — 43.80 1.90 50.35 0.65 2 64 32 — 47.44 2.06 54.38 0.55 2 64 64 — 50.58 2.19 57.40 0.45 3 16 16 16 47.84 2.07 54.15 0.54 3 32 16 16 50.98 2.21 61.70 0.41 3 32 32 16 48.89 2.12 55.86 0.56 3 32 32 32 53.71 2.32 67.33 0.29 表 2 不同模型评价指标

Table 2. Evaluation indicators of different models

模型 $ {\rm{MAE}}/{\mathrm{mm}} $ $ {\rm{MAPE}}/ {\text{%}} $ $ {\rm{RMSE}}/{\mathrm{mm}} $ $ {{{R^{\text{2}}}}} $ LSTM 51.01 2.21 63.85 0.36 GRU 48.25 2.10 59.58 0.38 TCN 61.27 2.64 66.41 0.32 CC−GRU 43.80 1.90 50.35 0.65 表 3 不同模型预测时间对比

Table 3. Comparison of prediction time of different models

模型 预测时间/s LSTM 0.96 GRU 0.88 TCN 0.08 CC−GRU 0.17 -

[1] 王国法,张良,李首滨,等. 煤矿无人化智能开采系统理论与技术研发进展[J]. 煤炭学报,2023,48(1):34-53.WANG Guofa,ZHANG Liang,LI Shoubin,et al. Progresses in theory and technological development of unmanned smart mining system[J]. Journal of China Coal Society,2023,48(1):34-53. [2] 王国法,富佳兴,孟令宇. 煤矿智能化创新团队建设与关键技术研发进展[J]. 工矿自动化,2022,48(12):1-15.WANG Guofa,FU Jiaxing,MENG Lingyu. Development of innovation team construction and key technology research in coal mine intelligence[J]. Journal of Mine Automation,2022,48(12):1-15. [3] HOLM M,BOHN C. Modelling of the cutting process of underground coal mining with shearer loaders for adaptive horizon control[C]. 19th SGEM International Multidisciplinary Scientific GeoConference,2019:423-430. DOI: 10.5593/sgem2019/1.3/S03.054. [4] YANG Jianjian,CHANG Boshen,ZHANG Yuchen,et al. CNN coal and rock recognition method based on hyperspectral data[J]. International Journal of Coal Science & Technology,2022,9(1). DOI: 10.1007/s40789-022-00516-x. [5] WANG Haijian,LIU Lili,ZHAO Xuemei,et al. Pre-perception and accurate recognition of coal–rock interface based on active excitation infrared characterization[J]. Journal of Computational Design and Engineering,2022,9(5):2040-2054. doi: 10.1093/jcde/qwac104 [6] SUN Chuanmeng,LI Xinyu,CHEN Jiaxin,et al. Coal-rock image recognition method for complex and harsh environment in coal mine using deep learning models[J]. IEEE Access,2023,11:80794-80805. doi: 10.1109/ACCESS.2023.3300243 [7] 张强,张润鑫,刘峻铭,等. 煤矿智能化开采煤岩识别技术综述[J]. 煤炭科学技术,2022,50(2):1-26.ZHANG Qiang,ZHANG Runxin,LIU Junming,et al. Review on coal and rock identification technology for intelligent mining in coal mines[J]. Coal Science and Technology,2022,50(2):1-26. [8] 毛明仓,张孝斌,张玉良. 基于透明地质大数据智能精准开采技术研究[J]. 煤炭科学技术,2021,49(1):286-293.MAO Mingcang,ZHANG Xiaobin,ZHANG Yuliang. Research on intelligent and precision mining technology based on transparent geological big data[J]. Coal Science and Technology,2021,49(1):286-293. [9] WANG Chen,ZHOU Jie. New advances in automatic shearer cutting technology for thin seams in Chinese underground coal mines[J]. Energy Exploration & Exploitation,2022,40(1):3-16. [10] 田立勇,毛君,王启铭. 基于采煤机摇臂惰轮轴受力分析的综合煤岩识别方法[J]. 煤炭学报,2016,41(3):782-787.TIAN Liyong,MAO Jun,WANG Qiming. Coal and rock identification method based on the force of idler shaft in shearer's ranging arm[J]. Journal of China Coal Society,2016,41(3):782-787. [11] 王廷栋. 基于遗传算法的采煤机截割控制系统研究[J]. 煤炭技术,2021,40(10):206-208.WANG Tingdong. Research on cutting control system of coal shearer based on genetic algorithm[J]. Coal Technology,2021,40(10):206-208. [12] 司垒,王忠宾,刘新华,等. 基于煤层分布预测的采煤机截割路径规划[J]. 中国矿业大学学报,2014,43(3):464-471.SI Lei,WANG Zhongbin,LIU Xinhua,et al. Cutting path planning of coal mining machine based on prediction of coal seam distribution[J]. Journal of China University of Mining & Technology,2014,43(3):464-471. [13] XIE Jiacheng,YAN Zewen,WANG Xuewen,et al. A memory cutting method of virtual shearer based on shape track prediction of AFC[J]. Mining,Metallurgy & Exploration,2021,38(5):2005-2019. [14] WANG Weibing,JING Zelin,ZHAO Shuanfeng,et al. Intelligent height adjustment method of shearer drum based on rough set significance reduction and fuzzy rough radial basis function neural network[J]. Applied Sciences,2023,13(5):2877-2898. doi: 10.3390/app13052877 [15] 梁耍,王世博,葛世荣,等. 综采工作面煤层三维模型动态修正方法研究[J]. 工矿自动化,2022,48(7):58-65,72.LIANG Shua,WANG Shibo,GE Shirong,et al. Study on dynamic modification method of 3D model of coal seam in fully mechanized working face[J]. Journal of Mine Automation,2022,48(7):58-65,72. [16] 崔涛. 基于真实开采数据的采运装备虚拟规划方法研究[D]. 太原:太原理工大学,2022.CUI Tao. Research on virtual planning method of mining and transportation equipment based on real mining data[D]. Taiyuan:Taiyuan University of Technology,2022. [17] 陈伟华,南鹏飞,闫孝姮,等. 基于深度学习的采煤机截割轨迹预测及模型优化[J]. 煤炭学报,2020,45(12):4209-4215.CHEN Weihua,NAN Pengfei,YAN Xiaoheng,et al. Prediction and model optimization of shearer memory cutting trajectory based on deep learning[J]. Journal of China Coal Society,2020,45(12):4209-4215. [18] 唐志章. 综采工作面集中控制关键技术研究[D]. 徐州:中国矿业大学,2021.TANG Zhizhang. Research on key technologies of centralized control in fully mechanized mining face[D]. Xuzhou:China University of Mining and Technology,2021. [19] BAI Shaojie,KOLTER J Z,KOLTUN V. Trellis networks for sequence modeling[C]. The 7th International Conference on Learning Representations,New Orleans,2018:1-18. [20] CHO K,MERRIENBOER B,GULCEHRE C,et al. Learning phrase representations using RNN encoder-decoder for statistical machine translation[C]. Conference on Empirical Methods in Natural Language Processing,Doha,2014:1724-1734. [21] RUÍZ-GUIROLA D E,LÓPEZ O L A,MONTEJO-SÁNCHEZ S,et al. Performance analysis of ML-based MTC traffic pattern predictors[J]. IEEE Wireless Communications Letters,2023,12(7):1144-1148. doi: 10.1109/LWC.2023.3264273 -

下载:

下载: