Health status evaluation of CNN-GRU mine motor based on adaptive multi-scale attention mechanism

-

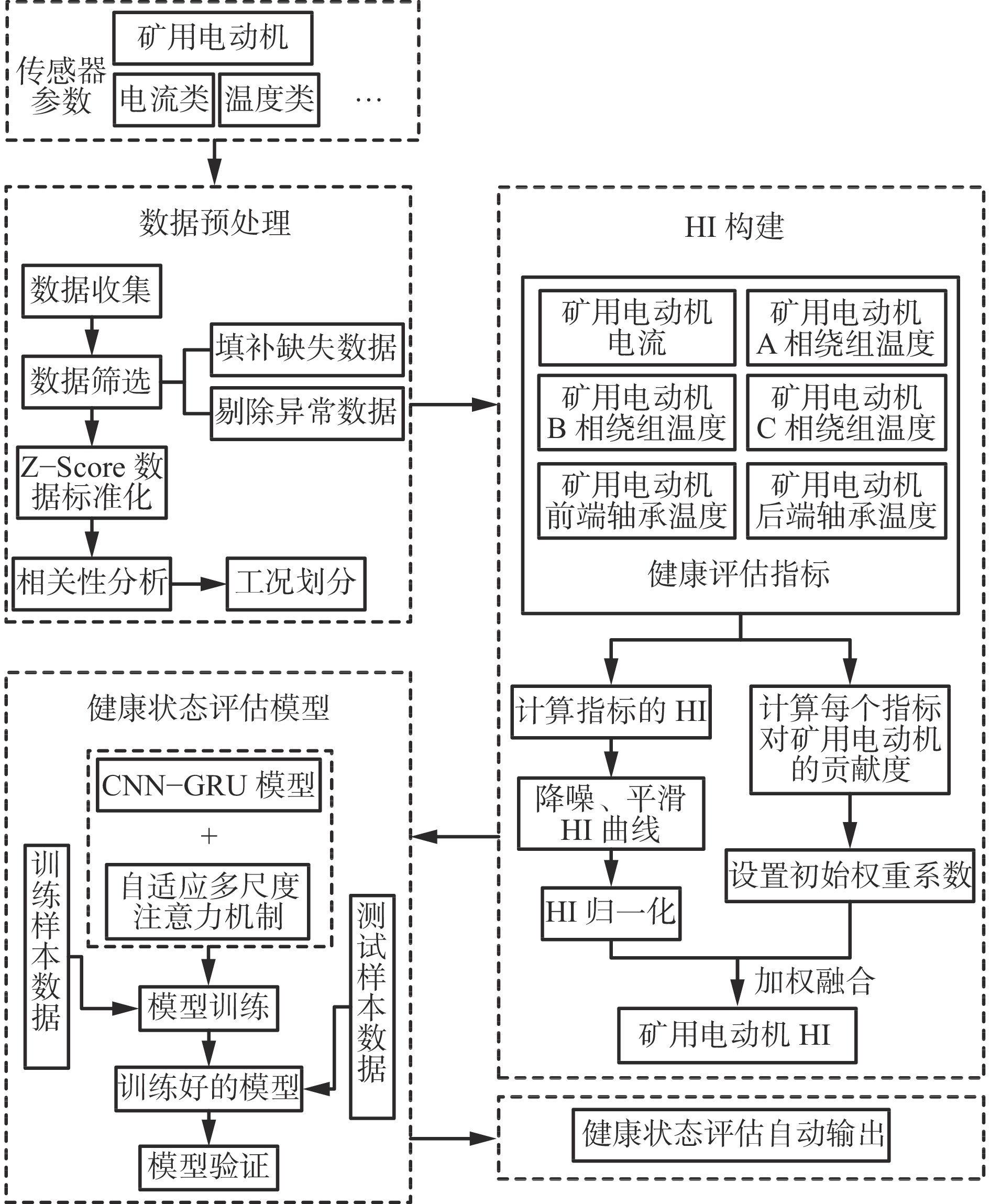

摘要: 利用多传感器信息融合技术进行电动机健康状态评估时,矿用电动机监测数据中存在异常值和缺失值,而卷积神经网络和循环神经网络等深度学习模型在数据质量下降严重的情况下难以有效提取数据特征和更新网络权重,导致梯度消失或爆炸等问题。针对上述问题,提出了一种基于自适应多尺度注意力机制的CNN−GRU(CNN−GRU−AMSA)模型,用于评估矿用电动机健康状态。首先,对传感器采集的电动机运行数据进行填补、剔除和标准化处理,并以环境温度变化作为依据对矿用电动机运行数据进行工况划分。然后,根据马氏距离计算出电动机电流、电动机三相绕组温度、电动机前端轴承温度和电动机后端轴承温度等健康评估指标的健康指数(HI),采用Savitzky–Golay滤波器对指标HI进行降噪、平滑、归一化处理,并结合主成分分析法计算的不同指标对矿用电动机的贡献度,对指标HI进行加权融合得到矿用电动机HI。最后,将矿用电动机HI输入CNN−GRU−AMSA模型中,该模型通过动态调整注意力权重,实现对不同尺度特征的信息融合,从而准确输出电动机健康状态评估结果。实验结果表明,与其他常见的深度学习模型CNN,CNN−GRU,CNN−LSTM,CNN−LSTM−Attention相比,CNN−GRU−AMSA模型在均方根误差、平均绝对误差、准确率、Macro F1及Micro F1等评价指标上更优,且预测残差的波动范围更小,稳定性更优。

-

关键词:

- 电动机健康状态评估 /

- 自适应多尺度注意力机制 /

- CNN−GRU /

- 多传感器信息融合 /

- 主成分分析

Abstract: When using multi-sensor information fusion technology to evaluate the health status of motors, there are outliers and missing values in the monitoring data of mine motors. However, deep learning models such as convolutional neural networks and recurrent neural networks find it difficult to effectively extract data features and update network weights when the data quality is severely degraded, resulting in problems such as vanishing or exploding gradients. In order to solve the above problems, A CNN-GRU (CNN-GRU-AMSA) model based on adaptive multi-scale attention mechanism is proposed to evaluate the health status of mine motors. Firstly, the model fills in, removes, and standardizes the motor operation data collected by sensors, and classifies the operating conditions of mine motors based on environmental temperature changes. Secondly, based on the Mahalanobis distance, the health index (HI) of health evaluation indicators such as motor current, three-phase temperature of motor winding, front bearing temperature of motor, and rear bearing temperature of motor are calculated. The Savitzky Golay filter is used to denoise, smooth, and normalize the HI indicator. Combining the contribution of different indicators calculated by principal component analysis method to mine motors, the weighted fusion of indicator HI is used to obtain the mine motor HI. Finally, the mine motor HI is input into the CNN-GRU-AMSA model, which dynamically adjusts attention weights to achieve information fusion of features at different scales, thereby accurately outputting the health status evaluation results of the motor. The experimental results show that compared with other common deep learning models such as CNN, CNN-GRU, CNN-LSTM, and CNN-LSTM Attention, the CNN-GRU-AMSA model performs better in evaluation metrics such as root mean square error, mean absolute error, accuracy, Macro F1, and MicroF1. The model has a smaller fluctuation range and better stability in predicting residuals. -

表 1 健康评估指标的个体贡献度与累计贡献度

Table 1. Individual and cumulative contribution degree of health assessment index

% 主成分 个体贡献度 累计贡献度 主成分1 85.68 85.68 主成分2 12.86 98.54 主成分3 0.94 99.48 主成分4 0.26 99.74 主成分5 0.24 99.98 主成分6 0.02 100.00 表 2 矿用电动机健康状态评估类别

Table 2. Mine motor health state assessment categories

状态 健康(S1) 良好(S2) 恶化(S3) 故障(S4) HI (0.8,1.0] (0.6,0.8] (0.3,0.6] [0,0.3] 表 3 工况1下不同模型性能比较

Table 3. Performance comparison of different models under working condition 1

模型 RMSE MAE MAX ACC/% Macro F1 Micro F1 CNN 0.0332 0.0235 0.2639 88.58 0.5648 0.5840 CNN−GRU 0.0386 0.0275 0.2656 89.29 0.6003 0.6374 CNN−LSTM 0.0310 0.0218 0.2467 88.20 0.5507 0.5602 CNN−LSTM−Attention 0.0312 0.0219 0.239 1 87.95 0.5415 0.5442 CNN−GRU−AMSA 0.009 6 0.006 4 0.2634 97.83 0.933 8 0.950 5 表 4 工况2下不同模型性能比较

Table 4. Performance comparison of different models under working condition 2

模型 RMSE MAE MAX ACC/% Macro F1 Micro F1 CNN 0.0300 0.0229 0.3287 89.96 0.7134 0.7867 CNN−GRU 0.0527 0.0349 0.3671 85.49 0.6128 0.6443 CNN−LSTM 0.0346 0.0261 0.3638 86.93 0.6486 0.6958 CNN−LSTM−Attention 0.0371 0.0276 0.3874 86.57 0.6405 0.6822 CNN−GRU−AMSA 0.0141 0.0080 0.3733 96.79 0.9359 0.9426 表 5 工况3下不同模型性能比较

Table 5. Performance comparison of different models under working condition 3

模型 RMSE MAE MAX ACC/% Macro F1c Micro F1 CNN 0.0384 0.0313 0.1284 78.31 0.4246 0.4373 CNN−GRU 0.0347 0.0259 0.1521 90.16 0.5995 0.6079 CNN−LSTM 0.0387 0.0293 0.1336 76.82 0.3979 0.3956 CNN−LSTM−Attention 0.0368 0.0286 0.1318 78.64 0.4252 0.4346 CNN−GRU−AMSA 0.0080 0.0057 0.0622 97.38 0.9567 0.9698 表 6 工况4下不同模型性能比较

Table 6. Performance comparison of different models under working condition 4

模型 RMSE MAE MAX ACC/% Macro F1c Micro F1 CNN 0.0445 0.0306 0.1986 96.93 0.6331 0.6419 CNN−GRU 0.0739 0.0443 0.2817 83.04 0.4527 0.4748 CNN−LSTM 0.0508 0.0337 0.2164 95.66 0.6177 0.6299 CNN−LSTM−Attention 0.0500 0.0334 0.2119 95.75 0.6186 0.6307 CNN−GRU−AMSA 0.0250 0.0129 0.1428 97.69 0.9650 0.8232 表 7 工况5下不同模型性能比较

Table 7. Performance comparison of different models under working condition 5

模型 RMSE MAE MAX ACC/% Macro F1 Micro F1 CNN 0.0288 0.0245 0.1152 91.01 0.5166 0.5521 CNN−GRU 0.0305 0.0238 0.1472 92.51 0.6401 0.6656 CNN−LSTM 0.0261 0.0218 0.1107 91.80 0.5336 0.5667 CNN−LSTM−Attention 0.0263 0.0222 0.1153 91.77 0.5322 0.5659 CNN−GRU−AMSA 0.0075 0.0054 0.0905 97.52 0.7687 0.8153 表 8 工况6下不同模型性能比较

Table 8. Performance comparison of different models under working condition 6

模型 RMSE MAE MAX ACC/% Macro F1 Micro F1 CNN 0.0253 0.0210 0.2475 95.22 0.4725 0.5213 CNN−GRU 0.0301 0.0244 0.2421 95.28 0.4750 0.5238 CNN−LSTM 0.0220 0.0187 0.2426 95.13 0.4689 0.5174 CNN−LSTM−Attention 0.0228 0.0195 0.2428 95.28 0.4750 0.5238 CNN−GRU−AMSA 0.0085 0.0053 0.2722 98.81 0.6242 0.6395 表 9 工况7下不同模型性能比较

Table 9. Performance comparison of different models under working condition 7

模型 RMSE MAE MAX ACC/% Macro F1 Micro F1 CNN 0.0290 0.0200 0.3783 87.87 0.4115 0.4394 CNN−GRU 0.0332 0.0226 0.3605 86.27 0.3880 0.4004 CNN−LSTM 0.0255 0.0177 0.3470 88.80 0.4520 0.5029 CNN−LSTM−Attention 0.0291 0.0206 0.3568 86.62 0.3846 0.4023 CNN−GRU−AMSA 0.0091 0.0064 0.2634 95.03 0.6081 0.6446 表 10 工况8下不同模型性能比较

Table 10. Performance comparison of different models under working condition 8

模型 RMSE MAE MAX ACC/% Macro F1 Micro F1 CNN 0.0378 0.0284 0.2710 85.00 0.5879 0.5724 CNN−GRU 0.0464 0.0334 0.2745 83.75 0.5756 0.5634 CNN−LSTM 0.0358 0.0241 0.2553 93.94 0.6394 0.6313 CNN−LSTM−Attention 0.0348 0.0236 0.2645 93.22 0.6352 0.6265 CNN−GRU−AMSA 0.0140 0.0090 0.2733 96.18 0.9447 0.9421 -

[1] SIDDIQUI K M,SAHAY K,GIRI V K,et al. Health monitoring and fault diagnosis in induction motor-a review[J]. International Journal of Advanced Research in Electrical,Electronics and Instrumentation Engineering,2014,3(1):6549-6565. [2] MEHALA N. Condition monitoring and fault diagnosis of induction motor using motor current signature analysis[D]. Kurushetra:National Institute of Technology,2010. [3] HOU Liqun,BERGMANN N W. Novel industrial wireless sensor networks for machine condition monitoring and fault diagnosis[J]. IEEE Transactions on Instrumentation and Measurement,2012,61(10):2787-2798. doi: 10.1109/TIM.2012.2200817 [4] 单增海,李志远,张旭,等. 基于多传感器信息融合和多粒度级联森林模型的液压泵健康状态评估[J]. 中国机械工程,2021,32(19):2374-2382.SHAN Zenghai,LI Zhiyuan,ZHANG Xu,et al. Health status assessment of hydraulic pumps based on multi-sensor information fusion and multi-grained cascade forest model[J]. China Mechanical Engineering,2021,32(19):2374-2382. [5] 雷亚国,许学方,蔡潇,等. 面向机械装备健康监测的数据质量保障方法研究[J]. 机械工程学报,2021,57(4):1-9. doi: 10.3901/JME.2021.04.001LEI Yaguo,XU Xuefang,CAI Xiao,et al. Research on data quality assurance for health condition monitoring of machinery[J]. Journal of Mechanical Engineering,2021,57(4):1-9. doi: 10.3901/JME.2021.04.001 [6] HU Weijun,ZHANG Yan,LI Lijie. Study of the application of deep convolutional neural networks (CNNs) in processing sensor data and biomedical images[J]. Sensors,2019,19(16). DOI: 10.3390/s19163584. [7] LIPTON Z C,BERKOWITZ J,ELKAN C. A critical review of recurrent neural networks for sequence learning[J]. Computer Science,2015. DOI: 10.48550/arXiv.1506.00019. [8] YANG Chao,JIANG Wenxiang,GUO Zhongwen. Time series data classification based on dual path CNN-RNN cascade network[J]. IEEE Access,2019,7:155304-155312. doi: 10.1109/ACCESS.2019.2949287 [9] 樊盼盼,袁逸萍,孙文磊,等. 融合多时段SCADA数据的风电动机组风险态势预测[J]. 计算机集成制造系统,2021,27(7):1993-2004.FAN Panpan,YUAN Yiping,SUN Wenlei,et al. Risk situation prediction of wind turbine based on multi-period SCADA data[J]. Computer Integrated Manufacturing Systems,2021,27(7):1993-2004. [10] 袁逸萍,樊盼盼,马占伟. 基于EEMD−MCNN−GRU的滚动轴承剩余使用寿命预测方法:CN202010290930.0[P]. 2022-07-12.YUAN Yiping,FAN Panpan,MA Zhanwei. Prediction method of remaining service life of rolling bearing based on EEMD-MCNN−GRU:CN202010290930.0[P]. 2022-07-12. [11] 赵小强,张亚洲. 利用改进卷积神经网络的滚动轴承变工况故障诊断方法[J]. 西安交通大学学报,2021,55(12):108-118.ZHAO Xiaoqiang,ZHANG Yazhou. Improved CNN-based fault diagnosis method for rolling bearings under variable working conditions[J]. Journal of Xi'an Jiaotong University,2021,55(12):108-118. [12] 康涛,段蓉凯,杨磊,等. 融合多注意力机制的卷积神经网络轴承故障诊断方法[J]. 西安交通大学学报,2022,56(12):68-77.KANG Tao,DUAN Rongkai,YANG Lei,et al. Bearing fault diagnosis using convolutional neural network based on a multi-attention mechanism[J]. Journal of Xi'an Jiaotong University,2022,56(12):68-77. [13] DING Yifei,JIA Minping,MIAO Qiuhua,et al. Remaining useful life estimation using deep metric transfer learning for kernel regression[J]. Reliability Engineering & System Safety,2021,212. DOI: 10.1016/j.ress.2021.107583. [14] 谢丽蓉,王斌,包洪印,等. 基于EEMD−WOA−LSSVM的超短期风电功率预测[J]. 太阳能学报,2021,42(7):290-296.XIE Lirong,WANG Bin,BAO Hongyin,et al. Super-short-term wind power forecasting based on EEMD-WOA-LSSVM[J]. Acta Energiae Solaris Sinica,2021,42(7):290-296. [15] MIAO Huihui,LI Bing,SUN Chuang,et al. Joint learning of degradation assessment and RUL prediction for aeroengines via dual-task deep LSTM networks[J]. IEEE Transactions on Industrial Informatics,2019,15(9):5023-5032. doi: 10.1109/TII.2019.2900295 [16] HAUKE J,KOSSOWSKI T. Comparison of values of Pearson's and Spearman's correlation coefficients on the same sets of data[J]. Quaestiones Geographicae,2011,30(2):87-93. doi: 10.2478/v10117-011-0021-1 [17] ZHANG Yong,XIN Yuqi,LIU Zhiwei,et al. Health status assessment and remaining useful life prediction of aero-engine based on BiGRU and MMoE[J]. Reliability Engineering & System Safety,2022,220. DOI: 10.1016/j.ress.2021.108263. [18] LIN Jinshan,CHEN Qian. Fault diagnosis of rolling bearings based on multifractal detrended fluctuation analysis and Mahalanobis distance criterion[J]. Mechanical Systems and Signal Processing,2013,38(2):515-533. doi: 10.1016/j.ymssp.2012.12.014 [19] SAVITZKY A,GOLAY M J E. Smoothing and differentiation of data by simplified least squares procedures[J]. Analytical Chemistry,1964,36(8):1627-1639. doi: 10.1021/ac60214a047 [20] HARBOLA S,COORS V. One dimensional convolutional neural network architectures for wind prediction[J]. Energy Conversion and Management,2019,195:70-75. doi: 10.1016/j.enconman.2019.05.007 [21] LIU Mingde,DING Lin,BAI Yulong. Application of hybrid model based on empirical mode decomposition,novel recurrent neural networks and the ARIMA to wind speed prediction[J]. Energy Conversion and Management,2021,233. DOI: 10.1016/j.enconman.2021.113917. [22] NIU Dongxiao,YU Min,SUN Lijie,et al. Short-term multi-energy load forecasting for integrated energy systems based on CNN-BiGRU optimized by attention mechanism[J]. Applied Energy,2022,313. DOI: 10.1016/j.apenergy.2022.118801. [23] SUN Heng,CHEN Miaomiao,WENG Jian,et al. Anomaly detection for in-vehicle network using CNN-LSTM with attention mechanism[J]. IEEE Transactions on Vehicular Technology,2021,70(10):10880-10893. doi: 10.1109/TVT.2021.3106940 [24] KIM T S,SOHN S Y. Multitask learning for health condition identification and remaining useful life prediction:deep convolutional neural network approach[J]. Journal of Intelligent Manufacturing,2021,32(8):2169-2179. doi: 10.1007/s10845-020-01630-w -

下载:

下载: