A method for extracting axis and constructing section in long roadway deformation monitoring

-

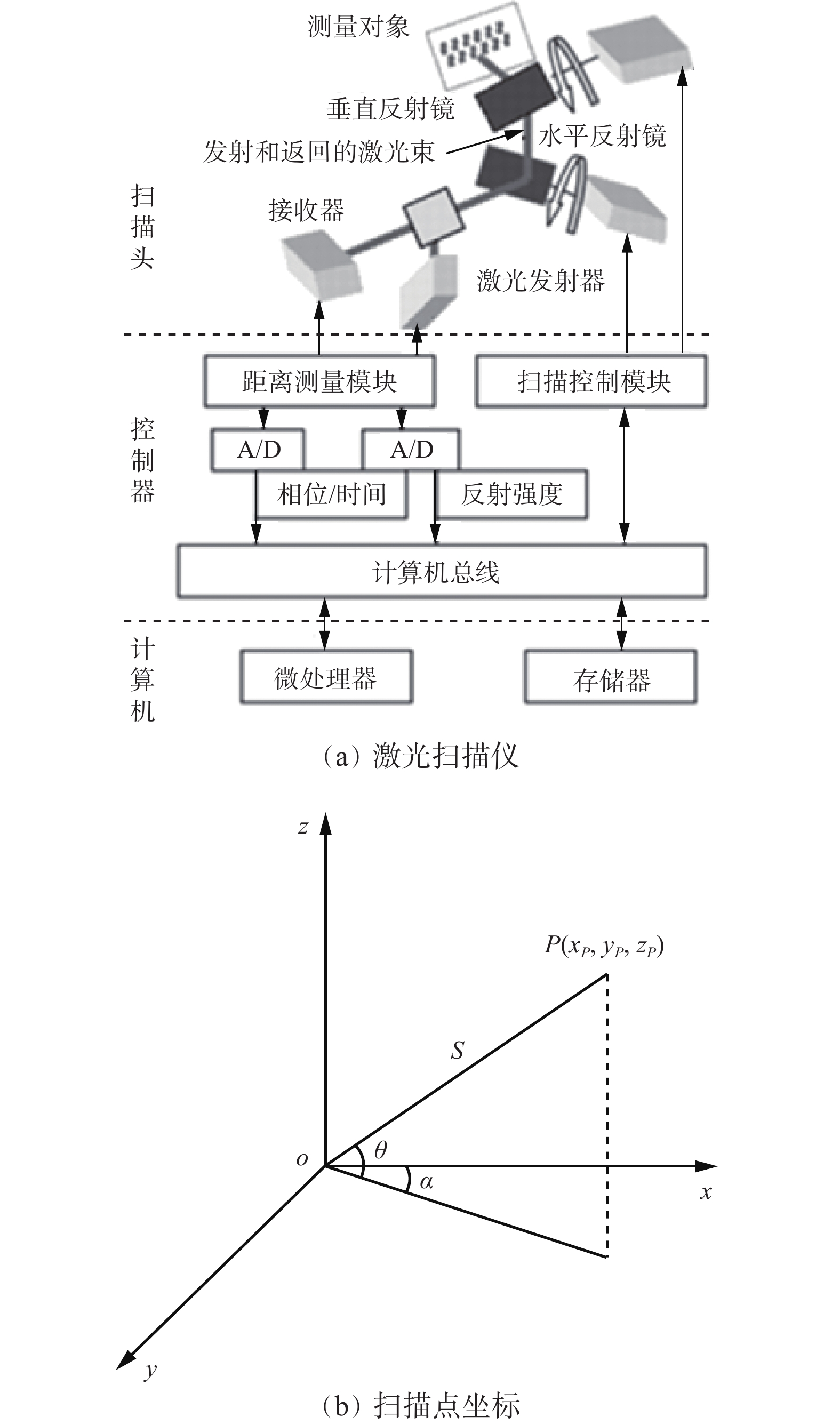

摘要: 三维激光扫描技术被广泛用于长巷道形变监测技术的研究中,但目前的研究存在多次扫描采集到的点云数据基准点移位现象;采集到的相邻点云数据公共特征不明显,多站点云拼接后会导致累计误差增大;超前巷道形变受超前支架的影响。针对上述问题,以传统十字点法中顶底板中点与两帮重点交叉的方法为基础,提出了一种基于最小二乘法的巷道中轴线提取方法。巷道定义的直角坐标系的原点位于激光束发射处,z轴位于激光扫描器的竖向扫描面内;x、y轴均位于仪器的横向扫描面内,中轴线反映了巷道整体的走向和姿态。在巷道掘进完成未受采动影响时,整条巷道进行第一遍扫描,通过最小二乘法确定整条巷道的中心点,将各中心点连接并拟合出一条完整的中轴线。在后续的巷道变形监测中,每监测一次均通过第一次的中点位置进行点云数据叠加,准确获得巷道断面内各个点云的变化情况,进而获得巷道的形变。基于拟合的中轴线构建巷道断面。采用三维激光扫描系统在塔山煤矿30507工作面回风巷对巷道形变进行了测试,结果表明:① 巷道形变随着测点距工作面距离的增大而变小,且30507工作面回风巷的超前影响范围为150 m,巷道形变的最大点位于底板临近采空区一侧。② 三维激光扫描和微震监测系统确定的超前范围接近,说明在进入150 m时支护煤体已经开始受力,且巷道形变的最大点位于底板临近采空区一侧,而不是十字点观测法观测的底板,证明三维激光扫描结果更为精确,且极大地降低了作业强度。Abstract: The 3D laser scanning technology is widely used in the research of deformation monitoring technology for long roadways. But there is a phenomenon of benchmark point displacement in the point cloud data collected through multiple scans in current research. The common features of adjacent point cloud data collected are not obvious, and the splicing of multi site clouds will lead to an increase in cumulative errors. The deformation of advanced roadways is affected by advanced supports. In order to solve the above problems, based on the traditional cross point method, which involves the intersection of the midpoint of the roof and floor and the two key points of the two sides, a method for extracting the axis of the roadway based on the least squares method is proposed. The origin of the rectangular coordinate system defined by the roadway is located at the laser beam emission point. The z-axis is located within the vertical scanning plane of the laser scanner. The x-axis and y-axis are located within the horizontal scanning plane of the scanner. The central axis reflects the overall direction and position and posture of the roadway. When the roadway excavation is completed without being affected by mining, the entire roadway is scanned for the first time, and the center point of the entire roadway is determined by the least squares method. Each center point is connected and fitted to form a complete central axis. In the subsequent monitoring of roadway deformation, point cloud data is superimposed based on the midpoint position of the first monitoring to accurately obtain the changes in various point clouds within the roadway cross-section, and thus obtain the deformation of the roadway. And the roadway section is constructed based on the fitted central axis. A 3D laser scanning system is used to test the deformation of the 30507 working face return air roadway in Tashan Coal Mine. The results showed the following points. ① The deformation of the roadway decreases with the increase of the distance from the measuring point to the working face, and the leading influence range of the 30507 working face return air roadway is 150 meters. The maximum point of roadway deformation is located on the side near the goaf of the floor. ② The advanced range determined by the 3D laser scanning and microseismic monitoring system is close, indicating that the supporting coal body has started to be under stress when entering 150 meters. The maximum point of roadway deformation is located on the side near the goaf of the floor, rather than the floor observed by the cross point observation method. This proves that the 3D laser scanning results are more accurate and greatly reduces the intensity of the operation.

-

表 1 测点数据

Table 1. Measuring point data

测点距工作面距离/m 最大形变量/mm 影响范围/m 150 3 10.3 120 6 12.6 70 11 18.8 表 2 不同监测方法精度对比

Table 2. Accuracy comparison of different monitoring methods

监测方法 超前范围/m 最大形变量/mm 最大形变位置 三维激光扫描 150 93 临空侧小煤柱靠底板处 微震监测系统 145 — — 十字点观测法 110 87 顶底板 -

[1] 姜阔胜,李良和,韩刘帮,等. 基于激光雷达技术的矿井巷道变形在线监测[J]. 北京信息科技大学学报(自然科学版),2020,35(5):1-4.JIANG Kuosheng,LI Lianghe,HAN Liubang,et al. On-line monitoring of mine tunnel deformation based on laser radar technology[J]. Journal of Beijing Information Science & Technology University,2020,35(5):1-4. [2] 王国法,杜毅博. 智慧煤矿与智能化开采技术的发展方向[J]. 煤炭科学技术,2019,47(1):1-10.WANG Guofa,DU Yibo. Development direction of intelligent coal mine and intelligent mining technology[J]. Coal Science and Technology,2019,47(1):1-10. [3] 杨洪涛,于印,许吉禅,等. 基于线扫描原理的煤矿巷道变形测量系统[J]. 工矿自动化,2022,48(7):113-117,148.YANG Hongtao,YU Yin,XU Jichan,et al. Coal mine roadway deformation measurement system based on line scanning principle[J]. Journal of Mine Automation,2022,48(7):113-117,148. [4] 李甲,王文杰,尹东. 基于改进灰色Verhulst模型的巷道变形破坏预警方法研究及应用[J]. 矿业安全与环保,2022,49(2):66-71.LI Jia,WANG Wenjie,YIN Dong. Research and application of early warning method of roadway deformation based on improved grey Verhulst model[J]. Mining Safety & Environmental Protection,2022,49(2):66-71. [5] 张华,李靖锋,魏红磊,等. 基于智能视频识别技术的智能化煤矿安全管理研究与应用[J]. 工矿自动化,2021,47(增刊1):10-13.ZHANG Hua,LI Jingfeng,WEI Honglei,et al. Research and application of intelligent coal mine safety management based on intelligent video recognition technology[J]. Industry and Mine Automation,2021,47(S1):10-13. [6] 张平松,李洁,李圣林,等. 三维地质建模在煤矿地质可视化中的应用分析[J]. 科学技术与工程,2022,22(5):1725-1740.ZHANG Pingsong,LI Jie,LI Shenglin,et al. Application status of 3D geological modeling in the development of coal mine intelligence[J]. Science Technology and Engineering,2022,22(5):1725-1740. [7] 王海军,刘再斌,雷晓荣,等. 煤矿巷道三维激光扫描关键技术及工程实践[J]. 煤田地质与勘探,2022,50(1):109-117. doi: 10.12363/issn.1001-1986.21.10.0589WANG Haijun,LIU Zaibin,LEI Xiaorong,et al. Key technologies and engineering practice of 3D laser scanning in coal mine roadways[J]. Coal Geology & Exploration,2022,50(1):109-117. doi: 10.12363/issn.1001-1986.21.10.0589 [8] 李梅,康济童,刘晖,等. 基于BIM与GIS的矿山巷道参数化三维建模技术研究[J]. 煤炭科学技术,2022,50(7):25-35.LI Mei,KANG Jitong,LIU Hui,et al. Study on parametric 3D modeling technology of mine roadway based on BIM and GIS[J]. Coal Science and Technology,2022,50(7):25-35. [9] 余洋,刘昌华,王世东,等. 三维激光扫描测量在植被参数提取中的应用[J]. 河南理工大学学报(自然科学版),2022,41(4):51-57.YU Yang,LIU Changhua,WANG Shidong,et al. Applications of 3D laser scanning technology in the extraction of vegetation parameters[J]. Journal of Henan Polytechnic University(Natural Science),2022,41(4):51-57. [10] 王腾,查剑锋,张民,等. 基于三维激光扫描的矿区道路沉陷监测研究[J]. 煤炭工程,2021,53(3):161-165.5.WANG Teng,ZHA Jianfeng,ZHANG Min,et al. Monitoring of mining area road subsidence based on 3D laser scanning[J]. Coal Engineering,2021,53(3):161-165. [11] 荣耀,曹琼,安晓宇,等. 综采工作面三维激光扫描建模关键技术研究[J]. 工矿自动化,2022,48(10):82-87.RONG Yao,CAO Qiong,AN Xiaoyu,et al. Research on key technologies of 3D laser scanning modeling in fully mechanized working face[J]. Journal of Mine Automation,2022,48(10):82-87. [12] 张琰,孔祥思,徐西桂. 基于移动三维激光扫描的隧道结构监测方案研究与应用[J]. 矿山测量,2021,49(1):20-25.ZHANG Yan,KONG Xiangsi,XU Xigui. Application and research of tunnel structure monitoring solution based on moving 3D laser scanning system[J]. Mine Surveying,2021,49(1):20-25. [13] 郭良林,周大伟,张德民,等. 基于激光点云的巷道变形监测及支护研究[J]. 煤矿安全,2020,51(8):178-183.GUO Lianglin,ZHOU Dawei,ZHANG Demin,et al. Research on deformation monitoring and supporting of tunnel based on laser point cloud[J]. Safety in Coal Mines,2020,51(8):178-183. [14] 刘晓阳,胡乔森,李慧娟. 基于三维激光扫描技术的巷道顶板监测研究[J]. 中国煤炭,2017,43(7):81-84,107.LIU Xiaoyang,HU Qiaosen,LI Huijuan. Research on coal mine roof monitoring based on three-dimensional laser scanning technology[J]. China Coal,2017,43(7):81-84,107. [15] 杨丁亮,邹进贵. 长大隧道点云的绝对定位配准方法[J]. 测绘通报,2022(增刊2):179-184.YANG Dingliang,ZOU Jingui. Point cloud registration method by absolute control in long tunnel[J]. Bulletin of Surveying and Mapping,2022(S2):179-184. [16] 金卓,王占利,张自宾. 基于三维激光扫描的矿井开拓巷道围岩变形测量技术研究[J]. 应用激光,2020,40(6):1120-1125.JIN Zhuo,WANG Zhanli,ZHANG Zibin. Research on measurement technology of surrounding rock deformation of mine development roadway based on 3D laser scanning[J]. Applied Laser,2020,40(6):1120-1125. [17] 郑理科,王健,李志远,等. 一种局部最优邻域法向量估算的巷道点云去噪方法[J]. 测绘科学,2023,48(4):140-148,171.ZHENG Like,WANG Jian,LI Zhiyuan,et al. A denoising method of roadway point cloud based on local optimal neighborhood normal vector estimation[J]. Science of Surveying and Mapping,2023,48(4):140-148,171. [18] 常巧梅,杨静,阎跃观. 基于三维激光扫描技术的巷道变形测量方法[J]. 煤炭技术,2023,42(6):30-32.CHANG Qiaomei,YANG Jing,YAN Yueguan. Roadway deformation measurement method based on 3D laser scanning technology[J]. Coal Technology,2023,42(6):30-32. [19] 李小鹏,刘少伟,付孟雄,等. 密集钻孔切顶卸压关键参数影响因素研究及应用[J]. 煤炭科学技术,2023,51(12):243-253.LI Xiaopeng,LIU Shaowei,FU Mengxiong,et al. Research and application of influencing factors of key parameters of roof cutting and pressure relief by dense drilling[J]. Coal Science and Technology,2023,51(12):243-253. [20] 黄炜伟. 基于粒子群的全空间瞬变电磁二维反演方法研究[J]. 工矿自动化,2021,47(4):79-84.HUANG Weiwei. Research on two-dimensional inversion method of transient electromagnetic in whole-space based on particle swarm[J]. Industry and Mine Automation,2021,47(4):79-84. [21] 张宇航,杨武年,任金铜,等. 高分二号卫星影像自适应模糊阈值法小波去噪[J]. 测绘通报,2019(3):32-35.ZHANG Yuhang,YANG Wunian,REN Jintong,et al. Adaptive fuzzy threshold method wavelet denoising of GF-2 satellite image[J]. Bulletin of Surveying and Mapping,2019(3):32-35. -

下载:

下载: