Research on flow compensation technology for hydraulic system in working face

-

摘要: 目前工作面液压系统的优化研究对连续推进过程中液压系统压力流量特性的分析较少,对液压系统压力流量波动问题缺乏简单有效的解决方案。针对工作面快速移架需求,以张家峁煤矿2−2煤层新建大采高工作面为工程背景,采用AMEsim软件建立了单台液压支架和成组液压支架仿真模型,基于自动跟机移架中千斤顶的动作时序,对煤炭开采过程中液压支架移架推溜过程进行仿真,分析了不同数量液压支架同时动作时工作面液压系统的压力流量变化情况,指出移架过慢的原因是液压支架瞬时需液量超过泵站最大流量,同时在液压支架成组运动过程中存在瞬时需液量不足和部分时刻泵站供液能力过剩的矛盾。针对液压系统间歇性大流量需求,提出了基于蓄能器的流量补偿技术,通过仿真验证了安装蓄能器后液压系统的压力波动被明显抑制,各千斤顶运动速度明显提升。在张家峁煤矿新建工作面对基于蓄能器的流量补偿技术进行现场试验,结果表明接入蓄能器后,液压系统平均压降降幅达74.1%,压力波动受到明显抑制,验证了流量补偿技术可满足液压系统间歇性大流量需求,为快速移架提供保障。Abstract: Currently, there is a lack of analysis on the pressure and flow characteristics of hydraulic systems during continuous propulsion in the optimization research of working face hydraulic systems. There is a lack of simple and effective solutions to the problem of pressure and flow fluctuations in hydraulic systems. In response to the demand for rapid support movement of the working face, with the construction of a new large mining height working face in the 2−2 coal seam of Zhangjiamao Coal Mine as the engineering background, a single hydraulic support and a group hydraulic support simulation model are established using AMEsim software. Based on the action timing of the jack in the automatic follow-up and support movement, the hydraulic support movement and sliding process during coal mining are simulated. The study analyzes the pressure and flow changes of the hydraulic system in the working face when different numbers of hydraulic supports act simultaneously. It is pointed out that the reason for the slow movement of the supports is that the instantaneous liquid demand of the hydraulic supports exceeds the maximum flow rate of the pump station. At the same time, there is a contradiction between insufficient instantaneous liquid demand and excess liquid supply capacity of the pump station at some times during the movement of the hydraulic supports. Aiming at the intermittent high flow demand of hydraulic systems, a flow compensation technology based on accumulators is proposed. Through simulation verification, the pressure fluctuation of the hydraulic system is significantly suppressed after the installation of accumulators, and the movement speed of each jack is significantly improved. On site experiments are conducted on the flow compensation technology based on accumulator in the new construction working face of Zhangjiamao Coal Mine. The results show that after the accumulator is connected, the average pressure drop of the hydraulic system decreases by 74.1%, and the pressure fluctuation is significantly suppressed. This verifies that the flow compensation technology can meet the intermittent high flow demand of the hydraulic system and provide guarantees for rapid support movement.

-

表 1 张家峁煤矿2−2煤层新建工作面中部液压支架部分参数

Table 1. Part parameters of hydraulic support in the middle of new working face of Zhangjiamao Coal Mine 2−2 coal seam

参数 值 参数 值 支架结构高度/mm 3 700~8 000 立柱中心距/mm 1 110 支架宽度/mm 1 950~2 200 推移步距/mm 800 支架中心距/mm 2 000 质量/t 80 表 2 液压支架立柱和千斤顶结构参数

Table 2. Structural parameters of hydraulic support columns and jacks

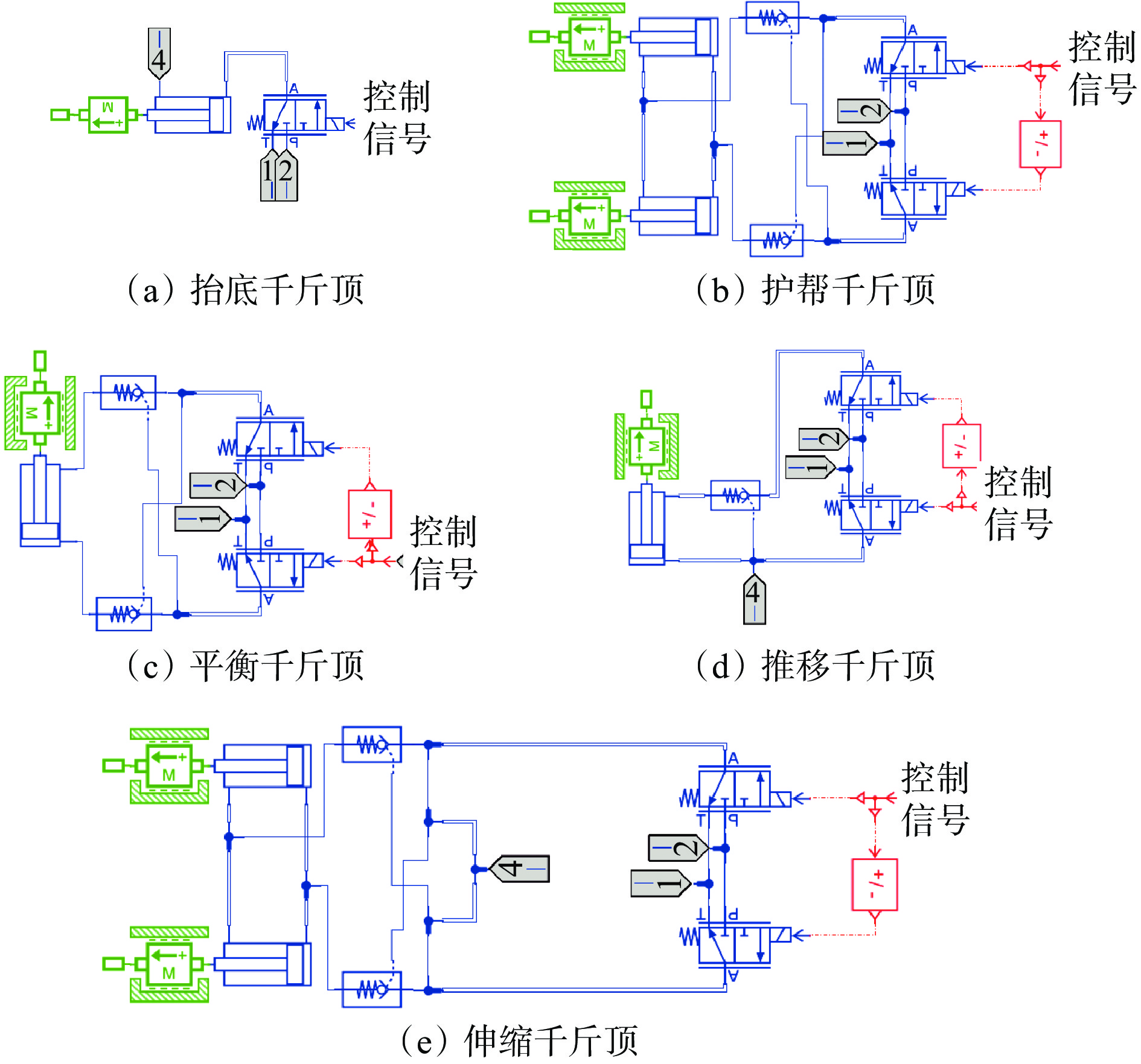

mm 结构名称 缸径 杆径 行程 立柱 530/380 500/355 2 090/2 090 推移千斤顶 250 160 1 080 平衡千斤顶 320 230 750 伸缩千斤顶 125 85 900 一级护帮千斤顶 160 105 900 二级护帮千斤顶 140 95 295 三级护帮千斤顶 80 60 360 抬底千斤顶 200 140 320 -

[1] 王国法,任怀伟,庞义辉,等. 煤矿智能化(初级阶段)技术体系研究与工程进展[J]. 煤炭科学技术,2020,48(7):1-27.WANG Guofa,REN Huaiwei,PANG Yihui,et al. Research and engineering progress of intelligent coal mine technical system in early stages[J]. Coal Science and Technology,2020,48(7):1-27. [2] 王国法. 煤矿智能化最新技术进展与问题探讨[J]. 煤炭科学技术,2022,50(1):1-27. doi: 10.3969/j.issn.0253-2336.2022.1.mtkxjs202201001WANG Guofa. New technological progress of coal mine intelligence and its problems[J]. Coal Science and Technology,2022,50(1):1-27. doi: 10.3969/j.issn.0253-2336.2022.1.mtkxjs202201001 [3] 庞义辉. 综采工作面智能化发展现状与展望[J]. 智能矿山,2020,1(1):21-29.PANG Yihui. Intelligent development situation and prospect of fully mechanized mining face[J]. Journal of Intelligent Mine,2020,1(1):21-29. [4] 王国法,刘峰,孟祥军,等. 煤矿智能化(初级阶段)研究与实践[J]. 煤炭科学技术,2019,47(8):1-36.WANG Guofa,LIU Feng,MENG Xiangjun,et al. Research and practice on intelligent coal mine construction(primary stage)[J]. Coal Science and Technology,2019,47(8):1-36. [5] 付翔,王然风,赵阳升,等. 基于交叠协同逻辑的液压支架运行自适应稳压供液控制方法[J]. 煤炭学报,2020,45(5):1891-1900.FU Xiang,WANG Ranfeng,ZHAO Yangsheng,et al. Self-adaptive control method of fluid feeding with steady pressure for hydraulic support based on overlapping synergetic logic[J]. Journal of China Coal Society,2020,45(5):1891-1900. [6] 方中喜,杜奇,牟东,等. 综采工作面支架液压系统优化设计[J]. 煤矿机械,2019,40(8):120-123.FANG Zhongxi,DU Qi,MU Dong,et al. Optimal design of support hydraulic system in fully mechanized mining face[J]. Coal Mine Machinery,2019,40(8):120-123. [7] 朱建领. 金鸡滩煤矿乳化液泵站系统优化设计[D]. 西安:西安科技大学,2017.ZHU Jianling. Design of system optimization of the emulsion pump station of Jinjitan Coal Mine[D]. Xi'an:Xi'an University of Science and Technology,2017. [8] 于玲,贾春强. 综采工作面支架液压系统仿真研究[J]. 煤矿机械,2014,35(2):56-58.YU Ling,JIA Chunqiang. Simulation research on hydraulic system of powered support in fully mechanized face[J]. Coal Mine Machinery,2014,35(2):56-58. [9] 任怀伟,张帅,薛国华,等. 液压支架自动跟机动态规律研究[J]. 工矿自动化,2023,49(9):47-54.REN Huaiwei,ZHANG Shuai,XUE Guohua,et al. Research on the dynamic law of automatic following of hydraulic support[J]. Journal of Mine Automation,2023,49(9):47-54. [10] 刘晓宾. 基于推移控制逻辑阀的液压支架推移控制系统优化研究[J]. 液压气动与密封,2021,41(12):13-15. doi: 10.3969/j.issn.1008-0813.2021.12.004LIU Xiaobin. Optimization of hydraulic support pushing control system with pushing control logic valve[J]. Hydraulics Pneumatics & Seals,2021,41(12):13-15. doi: 10.3969/j.issn.1008-0813.2021.12.004 [11] 司明,邬伯藩,王子谦. 综采工作面大流量智能供液系统研究[J]. 工矿自动化,2022,48(7):66-72.SI Ming,WU Bofan,WANG Ziqian. Research on large flow intelligent liquid supply system in fully mechanized working face[J]. Journal of Mine Automation,2022,48(7):66-72. [12] 付翔,王然风,赵阳升. 工作面支架液压系统仿真与稳压供液技术[J]. 煤炭学报,2018,43(5):1471-1478.FU Xiang,WANG Ranfeng,ZHAO Yangsheng. Investigation of hydraulic system simulation and fluid feeding technology with steady pressure of working face supports[J]. Journal of China Coal Society,2018,43(5):1471-1478. [13] 田成金. 智能反冲洗高压过滤站的工作原理与控制模式[J]. 煤矿开采,2015(6):44-46.TIAN Chengjin. Working principle and control mode of intelligent backwash high-pressure filter station[J]. Coal Mining Technology,2015(6):44-46. [14] 张宁波,郎瑞峰,王大龙,等. 采煤工作面远距离供液关键技术现状与展望[J]. 煤炭工程,2023,55(1):71-75.ZHANG Ningbo,LANG Ruifeng,WANG Dalong,et al. Current status and prospects of key technology for remote emulsion supply in coal mine[J]. Coal Engineering,2023,55(1):71-75. [15] 任怀伟,薛忠新,巩师鑫,等. 张家峁煤矿智能化建设与实践[J]. 中国煤炭,2020,46(12):54-60. doi: 10.3969/j.issn.1006-530X.2020.12.008REN Huaiwei,XUE Zhongxin,GONG Shixin,et al. Intelligent construction and its practice in Zhangjiamao Coal Mine[J]. China Coal,2020,46(12):54-60. doi: 10.3969/j.issn.1006-530X.2020.12.008 [16] ZIENKIEWICZ O C,TAYLOR R L,NITHIARAS P. The finite element method for fluid dynamics[M]. Oxford:Butterworth-Heinemann,2014. [17] 赵玉玲,孔令坡,谢恩情,等. 微乳型液压支架用乳化油HFAE10−5的研制及应用[J]. 煤炭科学技术,2013,41(增刊2):266-267.ZHAO Yuling,KONG Lingpo,XIE Enqing,et al. Application and research on emulsifying oil HFAE10-5 used in micro-emulsifying hydraulic support[J]. Coal Science and Technology,2013,41(S2):266-267. [18] 严升明,房风浩. 乳化液润滑的当量粘度系数[J]. 润滑与密封,2006(3):65-66,87.YAN Shengming,FANG Fenghao. The equivalent viscosity coefficients of lubrication with emulsion[J]. Lubrication Engineering,2006(3):65-66,87. [19] 周如林,李首滨,韦文术,等. 跟机液压系统压力流量耦合机理研究[J]. 煤炭科学技术,2020,48(5):129-136.ZHOU Rulin,LI Shoubin,WEI Wenshu,et al. Study on coupling mechanism of pressure and flow in following hydraulic system of mining face[J]. Coal Science and Technology,2020,48(5):129-136. [20] 张德生,祝琨,张赛,等. 综采工作面快速采煤技术现状及发展趋势[J]. 煤炭工程,2021,53(11):1-5.ZHANG Desheng,ZHU Kun,ZHANG Sai. et al. Present situation and prospect of rapid mining technology in fully-mechanized mining face[J]. Coal Engineering,2021,53(11):1-5. -

下载:

下载: