Hydraulic fracturing and punching integration enhanced permeability gas extraction technology

-

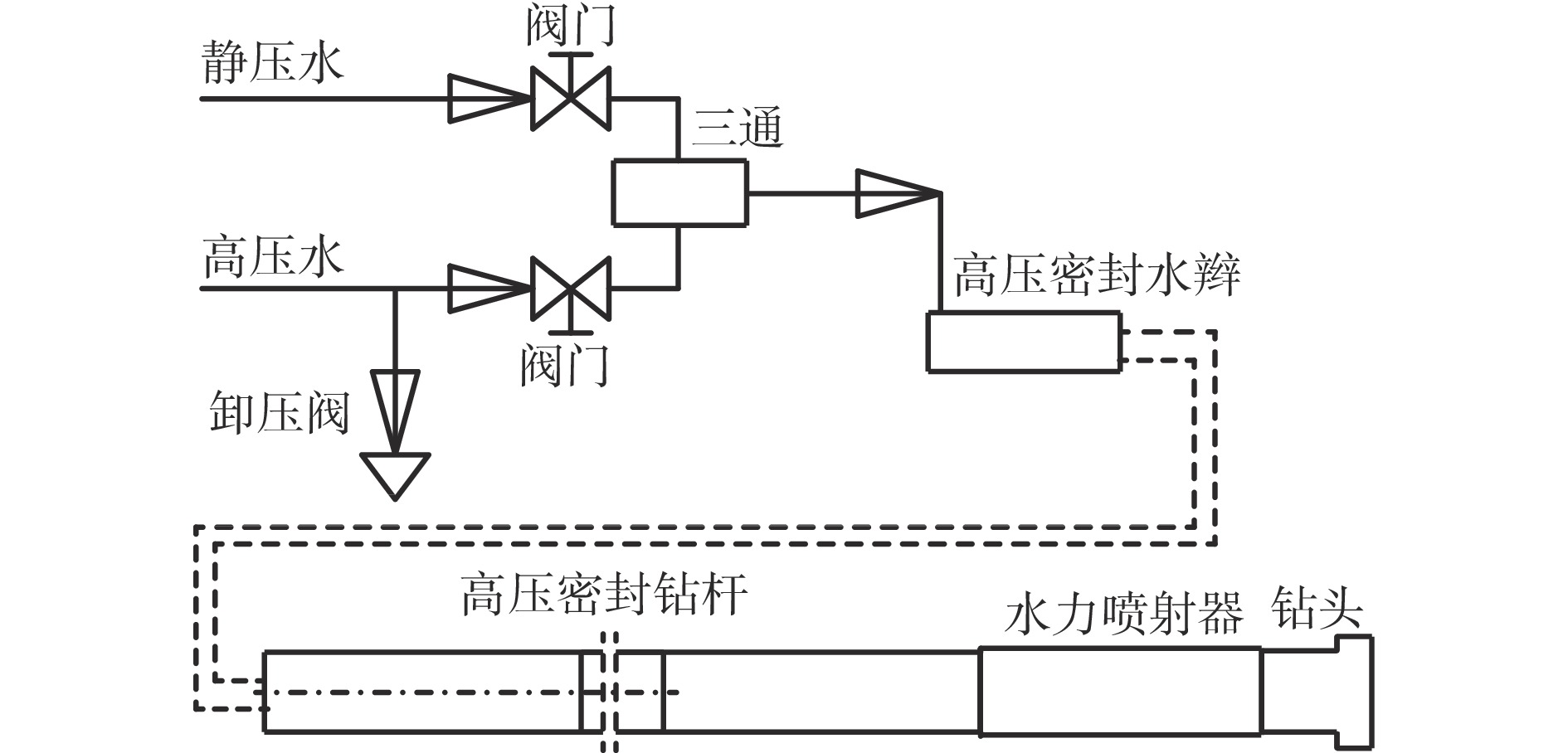

摘要: 现有的水力压裂、水力冲孔、水力掏槽、水力割缝等煤矿井下水力增透技术工艺复杂、适应条件单一、劳动强度大,而钻冲一体化、钻扩一体化、水力冲/压一体化等技术对硬煤增透效果不理想,且存在工序繁琐、不能连续作业等问题。针对上述问题,提出了一种水力压冲一体化增透抽采瓦斯技术,在钻进过程中利用高压水射流定点(定向、分段)对煤层实施水力增透作业,可实现集打钻、对软煤水力冲孔及对硬煤水力喷射压裂的一体化作业。揭示了水力压冲一体化增透原理,即通过水力冲孔将软煤层的部分煤体冲出,实现软煤层出煤卸压增透,对硬煤层进行定点水力喷射压裂,实现硬煤层造缝增透;研制了水力压冲一体化钻具,满足高泵压、大排量的要求,具备较强的破岩和排屑能力,其工序简单、可操控性强;给出了高压水射流冲孔和水力喷射压裂时的钻具操控方法,探讨了钻进时冲压工艺和退钻时冲压工艺。在某矿16101底抽巷使用水力压冲一体化钻具进行了现场工程试验,结果表明:在软煤段进行水力冲孔作业,比传统水力冲孔缩短时间60%~80%,而单孔出煤量增加了约2倍,单孔平均百米瓦斯抽采纯量提高了1倍;在硬煤段进行水力喷射压裂作业,单孔平均百米瓦斯抽采纯量比传统水力冲孔提高了2倍。Abstract: The existing hydraulic fracturing, hydraulic punching, hydraulic slotting, hydraulic cutting and other underground hydraulic permeability enhancement technologies in coal mines have complex processes, single adaptability conditions, and high labor intensity. However, drilling and punching integration, drilling and expansion integration, hydraulic punching/fracturing integration and other technologies are not ideal for enhancing the permeability of hard coal. There are problems such as cumbersome processes and inability to operate continuously. In order to solve the above problems, a hydraulic fracturing and punching integration enhanced permeability gas extraction technology is proposed. During the drilling process, high-pressure water jet is used to perform hydraulic enhanced permeability operations on coal seams at fixed points (directional, segmented). It can achieve integrated drilling, hydraulic punching of soft coal, and hydraulic injection fracturing of hard coal. The study reveals the principle of hydraulic fracturing and punching integration permeability enhancement. The hydraulic punching is used to flush out part of the coal body in soft coal seams, achieving pressure relief and permeability enhancement of soft coal seams. The fixed-point hydraulic jet fracturing is performed on hard coal seams, achieving fracture formation and permeability enhancement in hard coal seams. The drilling tool of hydraulic fracturing and punching integration is developed to meet the requirements of high pump pressure and large displacement. The drilling tool has strong rock breaking and chip removal capabilities. The process is simple and controllable. The drilling tool control methods for high-pressure water jet punching and hydraulic jet fracturing are provided. The stamping process during drilling and stamping process during drill withdrawal are discussed. The on site engineering tests are conducted using fracturing and punching integration drilling tools in the 16101 bottom drainage roadway of a coal mine. The results show that hydraulic punching operation in the soft coal section shortens the time by 60% to 80% compared to traditional hydraulic punching. The coal output from a single hole increases by about 2 times, and the average gas extraction purity per 100 meters per hole increases by 1 time. The hydraulic jet fracturing operation is carried out in the hard coal section. The average gas extraction purity per 100 meters per hole increases by 2 times compared to traditional hydraulic punching.

-

表 1 钻孔设计参数

Table 1. Borehole design parameters

孔号 倾角 /(°) 方位 孔径/mm 岩段/m 煤段/m 总长/m 3 48.0 下帮 94 13.6 8.1 21.8 5 83.5 下帮 94 10.5 6.5 17.0 8 57.5 上帮 94 13.2 8.1 21.3 -

[1] 陶云奇,张超林,许江,等. 水力冲孔卸压增透物理模拟试验及效果评价[J]. 重庆大学学报,2018,41(10):69-77. doi: 10.11835/j.issn.1000-582X.2018.10.008TAO Yunqi,ZHANG Chaolin,XU Jiang,et al. Effect evaluation on pressure relief and permeability improvement of hydraulic flushing physical experiment[J]. Journal of Chongqing University,2018,41(10):69-77. doi: 10.11835/j.issn.1000-582X.2018.10.008 [2] 李国富,李超,霍春秀,等. 山西重点煤矿区瓦斯梯级利用关键技术与工程示范[J]. 煤田地质与勘探,2022,50(9):42-50. doi: 10.12363/issn.1001-1986.22.07.0558LI Guofu,LI Chao,HUO Chunxiu,et al. Key technology and engineering demonstration for cascade utilization of gas in key coal mining areas of Shanxi Province,China[J]. Coal Geology & Exploration,2022,50(9):42-50. doi: 10.12363/issn.1001-1986.22.07.0558 [3] 郭超奇,赵继展,李小建,等. 中硬低渗煤层定向长钻孔水力压裂瓦斯高效抽采技术与应用[J]. 煤田地质与勘探,2020,48(6):103-108,115. doi: 10.3969/j.issn.1001-1986.2020.06.014GUO Chaoqi,ZHAO Jizhan,LI Xiaojian,et al. Technology and application of high efficiency gas extraction by directional long borehole hydraulic fracturing in coal seams of medium hardness and low permeability[J]. Coal Geology & Exploration,2020,48(6):103-108,115. doi: 10.3969/j.issn.1001-1986.2020.06.014 [4] 张帅,刘志伟,韩承强,等. 高突低渗透煤层超高压水力割缝卸压增透研究[J]. 煤炭科学技术,2019,47(4):147-151.ZHANG Shuai,LIU Zhiwei,HAN Chengqiang,et al. Study on coal pressure relief and permeability increase through ultra-high pressure hydraulic slotting in high outburst and low permeability coal seam[J]. Coal Science and Technology,2019,47(4):147-151. [5] 刘见中,孙海涛,雷毅,等. 煤矿区煤层气开发利用新技术现状及发展趋势[J]. 煤炭学报,2020,45(1):258-267.LIU Jianzhong,SUN Haitao,LEI Yi,et al. Current situation and development trend of coalbed methane development and utilization technology in coal mine area[J]. Journal of China Coal Society,2020,45(1):258-267. [6] 陈洪涛,李太训. 薛湖煤矿超高压水力割缝工艺参数优化试验[J]. 工矿自动化,2020,46(1):90-94.CHEN Hongtao,LI Taixun. Optimization test of ultra-high pressure hydraulic slotting process parameters in Xuehu Coal Mine[J]. Industry and Mine Automation,2020,46(1):90-94. [7] 姜婷婷,张建华,黄刚. 煤岩水力压裂裂缝扩展形态试验研究[J]. 岩土力学,2018,39(10):3677-3684.JIANG Tingting,ZHANG Jianhua,HUANG Gang. Experimental study of fracture geometry during hydraulic fracturing in coal[J]. Rock and Soil Mechanics,2018,39(10):3677-3684. [8] 董志勇. 煤矿井下水力压裂切顶卸压护巷技术应用研究[J]. 工矿自动化,2019,45(10):99-103.DONG Zhiyong. Application research on roadway protection technology by hydraulic fracturing roof cutting pressure relief in underground coal mine[J]. Industry and Mine Automation,2019,45(10):99-103. [9] 张福旺,秦汝祥,杨应迪. 密集水力冲孔增透抽采瓦斯试验研究[J]. 煤炭科学技术,2022,50(4):142-148.ZHANG Fuwang,QIN Ruxiang,YANG Yingdi. Experimental study on gas extraction with intensive hydraulic punching and penetration enhancement[J]. Coal Science and Technology,2022,50(4):142-148. [10] 王恩元,汪皓,刘晓斐,等. 水力冲孔孔洞周围煤体地应力和瓦斯时空演化规律[J]. 煤炭科学技术,2020,48(1):39-45.WANG Enyuan,WANG Hao,LIU Xiaofei,et al. Spatio temporal evolution of geostress and gas field around hydraulic punching borehole in coal seam[J]. Coal Science and Technology,2020,48(1):39-45. [11] 刘东,刘文. 水力冲孔压裂卸压增透抽采瓦斯技术研究[J]. 煤炭科学技术,2019,47(3):136-141.LIU Dong,LIU Wen. Research on gas extraction technology:hydraulic stamping and hydrofracture to pressure relief and permeability improvement[J]. Coal Science and Technology,2019,47(3):136-141. [12] GU Beifang,HU Ruili,WANG Longkang,et al. Study on the influence rule of high-pressure water jet nozzle parameters on the effect of hydraulic slotting[J]. Geofluids,2022(8):1-10. [13] 杜金磊,张民波,张电吉,等. 低透气突出煤层水力割缝协同卸压增透技术[J]. 工矿自动化,2021,47(7):98-105.DU Jinlei,ZHANG Minbo,ZHANG Dianji,et al. Hydraulic cutting cooperative pressure relief and permeability enhancement technology in low permeability outburst coal seam[J]. Industry and Mine Automation,2021,47(7):98-105. [14] 王正帅. 碎软煤层顺层钻孔水力割缝增透技术研究[J]. 煤炭科学技术,2019,47(8):147-151.WANG Zhengshuai. Research on hydraulic slitting anti-reflection technology for borehole drilled along broken soft coal seam[J]. Coal Science and Technology,2019,47(8):147-151. [15] 梁银权,王进尚,冯星宇. 高瓦斯低透气性煤层深钻孔高压水力割缝增透技术[J]. 煤炭工程,2019,51(6):99-102.LIANG Yinquan,WANG Jinshang,FENG Xingyu. Permeability-increasing technology of deep drilling supper-high pressure hydraulic cutting in high gas and low permeability coal seam[J]. Coal Engineering,2019,51(6):99-102. [16] 卢义玉,李瑞,鲜学福,等. 地面定向井+水力割缝卸压方法高效开发深部煤层气探讨[J]. 煤炭学报,2021,46(3):876-884.LU Yiyu,LI Rui,XIAN Xuefu,et al. Discussion on the efficient exploitation method of deep coalbed methane with pressure relief by ground directional well+hydraulic slotting[J]. Journal of China Coal Society,2021,46(3):876-884. [17] 王正帅. 水力化增透技术在碎软煤层瓦斯抽采中的应用研究[J]. 煤炭工程,2021,53(2):85-89.WANG Zhengshuai. Application of hydraulic permeability-enhancing in gas extraction of broken soft coal seam in Xinjiang[J]. Coal Engineering,2021,53(2):85-89. [18] 司俊廷. 冲压一体化联合增透技术在软煤层瓦斯治理中的应用研究[J]. 中国矿业,2020,29(增刊2):348-352. doi: 10.12075/j.issn.1004-4051.2020.S2.017SI Junting. Research on the application of stamping integration combined anti-reflection technology in gas treatment of soft coal seam[J]. China Mining Magazine,2020,29(S2):348-352. doi: 10.12075/j.issn.1004-4051.2020.S2.017 [19] 苏现波,宋金星,郭红玉,等. 煤矿瓦斯抽采增产机制及关键技术[J]. 煤炭科学技术,2020,48(12):1-30.SU Xianbo,SONG Jinxing,GUO Hongyu,et al. Increasing production mechanism and key technology of gas extraction in coal mines[J]. Coal Science and Technology,2020,48(12):1-30. [20] 于世耀. 钻冲压一体化瓦斯抽采增产技术及应用研究[D]. 焦作:河南理工大学,2020.YU Shiyao. Study on the stimulation technology and application of gas drainage by hydraulic drilling flushing and fracturing integration[D]. Jiaozuo:Henan Polytechnic University,2020. [21] SONG Jinxing,ZHANG Huiyan,YU Shiyao,et al. Application of integrated drilling and stamping technology in gas extraction through layer drilling[J]. Energy Exploration & Exploitation,2022,40(4):1113-1130. -

下载:

下载: