Research and application of hydraulic slotting gas extraction technology in coal seams containing gangue

-

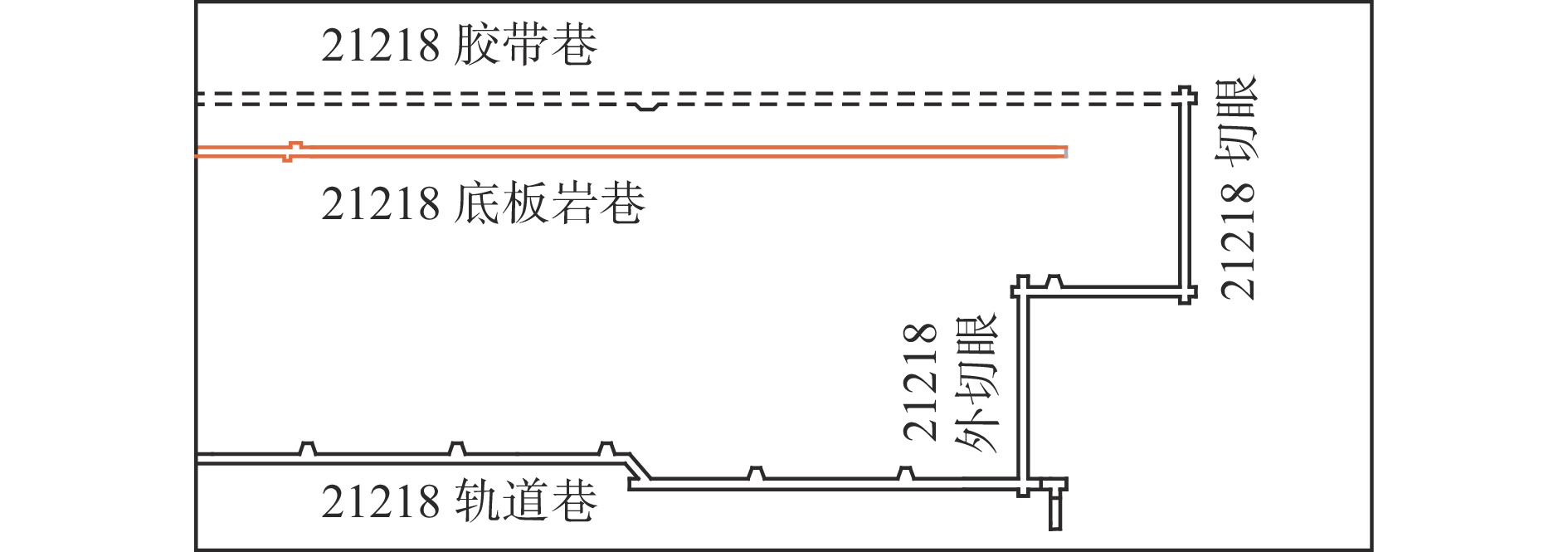

摘要: 为研究水力割缝强化瓦斯抽采技术在含夹矸煤层中的应用,通过理论分析得出,与普通钻孔相比,水力割缝钻孔可通过增加煤层渗透率、煤体暴露面积、瓦斯流动通道3个方面强化瓦斯抽采,并建立了考虑孔隙率和渗透率变化的煤层瓦斯流动控制方程。以东庞矿21218工作面为工程背景,采用COMSOL数值模拟软件建立了含夹矸煤层水力割缝瓦斯抽采数值模型,通过对煤层瓦斯流动控制方程进行解算,研究了不同割缝高度、不同钻孔间距条件下,水力割缝瓦斯抽采钻孔的瓦斯压力分布规律,从而确定了上煤层割缝0.3 m、下煤层割缝0.1 m、钻孔间距7.5 m的水力割缝瓦斯抽采钻孔施工参数。基于上述参数,在东庞矿21218工作面现场施工28组、每组7个水力割缝钻孔,对含夹矸煤层瓦斯进行抽采作业,结果表明:与普通钻孔相比,水力割缝钻孔的每百米巷道施工工程量减少了28.51%,瓦斯抽采纯量由11.53 万m3提升至21.43 万m3,增幅为85.86%,巷道掘进期间掘进工作面平均瓦斯体积分数由0.06%降至0.01%,瓦斯抽采效果好,且有效提高了瓦斯抽采效率。Abstract: In order to study the application of hydraulic slotting enhanced gas extraction technology in coal seams containing gangue, theoretical analysis shows the following points. Compared with ordinary drilling, hydraulic slotting borehole can enhance gas extraction by increasing coal seam permeability, coal body exposure area, and gas flow channels. A coal seam gas flow control equation has been established considering changes in porosity and permeability. Taking the 21218 working face of Dongpang Mine as the engineering background, a numerical model for hydraulic slotting gas extraction in coal seams containing gangue is established by using COMSOL numerical simulation software. By solving the control equation of coal seam gas flow, the gas pressure distribution law of hydraulic slotting gas extraction borehole under different slotting heights and drilling spacing conditions is studied. The construction parameters for hydraulic slotting gas extraction borehole with a slotting of 0.3 m in the upper coal seam, a slotting of 0.1 m in the lower coal seam, and a borehole spacing of 7.5 m are determined. Based on the above parameters, 28 groups of 7 hydraulic slotting borehole are constructed on-site at the 21218 working face of Dongpang Mine to extract gas from coal seams containing gangue. The results show that compared with ordinary borehole, the construction quantity of hydraulic slotting borehole per 100 meters of roadway decreases by 28.51%. The net amount of gas extraction increases from 115300 m3 to 214300 m3 with an increase of 85.86%. The average gas volume fraction of the excavation working face during the roadway excavation period decreases from 0.06% to 0.01%. The gas extraction effect is good and the gas extraction efficiency is effectively improved.

-

表 1 数值模型计算参数

Table 1. Calculation parameters of the numerical model

参数 数值 参数 数值 初始地应力/MPa 15.50 初始瓦斯压力/MPa 1.15 夹矸弹性模量/GPa 3.45 吸附常数a/(m3·kg−1) 24 夹矸泊松比 0.29 吸附常数b/MPa−1 1 夹矸黏聚力/MPa 4.63 煤的灰分/% 4.38 夹矸内摩擦角/(°) 27 煤的水分/% 1.85 夹矸密度/(kg·m−3) 2 530 瓦斯分子量/(g·mol−1) 16 煤层弹性模量/GPa 2.35 气体常数/(J·mol−1·K−1) 8.314 煤层泊松比 0.25 煤层温度/K 293 煤层黏聚力/MPa 2.97 初始渗透率/m2 1.14×10−8 煤层内摩擦角/(°) 28 瓦斯动力黏度/(Pa·s) 1.84×10−5 煤层密度/(kg·m−3) 1 430 初始孔隙率 0.06 表 2 普通钻孔和水力割缝钻孔瓦斯抽采效果对比

Table 2. Comparison of gas extraction effects between ordinary boreholes and hydraulic slotting boreholes

指标 普通钻孔 水力割缝钻孔 覆盖巷道长度/m 206 202 工程量/m 10 299 7 220 抽采纯量/万m3 11.53 21.43 掘进工作面平均瓦斯体积分数/% 0.06 0.01 -

[1] 胡千庭,周世宁,周心权. 煤与瓦斯突出过程的力学作用机理[J]. 煤炭学报,2008,33(12):1368-1372. doi: 10.3321/j.issn:0253-9993.2008.12.008HU Qianting,ZHOU Shining,ZHOU Xinquan. Mechanical mechanism of coal and gas outburst process[J]. Journal of China Coal Society,2008,33(12):1368-1372. doi: 10.3321/j.issn:0253-9993.2008.12.008 [2] 张保法,刘中一. “三软”高突煤层水力冲孔工艺优化[J]. 煤矿安全,2013,44(7):141-143. doi: 10.13347/j.cnki.mkaq.2013.07.074ZHANG Baofa,LIU Zhongyi. Hydraulic punching technology optimization in "three-soft" severe outburst coal seam[J]. Safety in Coal Mines,2013,44(7):141-143. doi: 10.13347/j.cnki.mkaq.2013.07.074 [3] 周福宝,孙玉宁,李海鉴,等. 煤层瓦斯抽采钻孔密封理论模型与工程技术研究[J]. 中国矿业大学学报,2016,45(3):433-439. doi: 10.13247/j.cnki.jcumt.000498ZHOU Fubao,SUN Yuning,LI Haijian,et al. Research on the theoretical model and engineering technology of the coal seam gas drainage hole sealing[J]. Journal of China University of Mining & Technology,2016,45(3):433-439. doi: 10.13247/j.cnki.jcumt.000498 [4] 韩颖,宋德尚. 低渗煤层高压水射流割缝增透技术试验研究[J]. 中国安全生产科学技术,2014,10(12):35-39.HAN Ying,SONG Deshang. Experimental study on permeability improvement technology by cutting seam using high pressure water jet in coal seam with low permeability[J]. Journal of Safety Science and Technology,2014,10(12):35-39. [5] 王登科,彭明,付启超,等. 瓦斯抽采过程中的煤层透气性动态演化规律与数值模拟[J]. 岩石力学与工程学报,2016,35(4):704-712. doi: 10.13722/j.cnki.jrme.2015.0931WANG Dengke,PENG Ming,FU Qichao,et al. Evolution and numerical simulation of coal permeability during gas drainage in coal seams[J]. Chinese Journal of Rock Mechanics and Engineering,2016,35(4):704-712. doi: 10.13722/j.cnki.jrme.2015.0931 [6] 秦江涛,陈玉涛. 高压水力割缝和压裂联合增透技术及应用[J]. 矿业安全与环保,2016,43(6):29-31,36. doi: 10.3969/j.issn.1008-4495.2016.06.008QIN Jiangtao,CHEN Yutao. Combined permeability improvement technology of high-pressure hydraulic slotting with hydraulic fracturing and its application[J]. Mining Safety & Environmental Protection,2016,43(6):29-31,36. doi: 10.3969/j.issn.1008-4495.2016.06.008 [7] 吴教锟. 水力割缝增透技术在石门揭煤中的应用[J]. 煤矿开采,2017,22(2):93-95. doi: 10.13532/j.cnki.cn11-3677/td.2017.02.023WU Jiaokun. Application of hydraulic slotting and permeability technology in uncovering coal in crosscut[J]. Coal Mining Technology,2017,22(2):93-95. doi: 10.13532/j.cnki.cn11-3677/td.2017.02.023 [8] 贾同千,饶孜,何庆兵,等. 复杂地质低渗煤层水力压裂−割缝综合瓦斯增透技术研究[J]. 中国安全生产科学技术,2017,13(4):59-64.JIA Tongqian,RAO Zi,HE Qingbing,et al. Research on comprehensive gas permeability improvement technology by hydraulic fracturing and slotting in coal seam with complex geological conditions and low permeability[J]. Journal of Safety Science and Technology,2017,13(4):59-64. [9] 刘志伟,高振勇. 超高压水力钻割一体化增透技术参数试验考察[J]. 煤矿开采,2019,24(1):133-135. doi: 10.13532/j.cnki.cn11-3677/td.2019.01.029LIU Zhiwei,GAO Zhenyong. Parameters experiment of integrated anti-reflection technology of super high pressure hydraulic cutting[J]. Coal Mining Technology,2019,24(1):133-135. doi: 10.13532/j.cnki.cn11-3677/td.2019.01.029 [10] 张帅,刘志伟,韩承强,等. 高突低渗透煤层超高压水力割缝卸压增透研究[J]. 煤炭科学技术,2019,47(4):147-151. doi: 10.13199/j.cnki.cst.2019.04.024ZHANG Shuai,LIU Zhiwei,HAN Chengqiang,et al. Study on coal pressure relief and permeability increase through ultra-high pressure hydraulic slotting in high outburst and low permeability coal seam[J]. Coal Science and Technology,2019,47(4):147-151. doi: 10.13199/j.cnki.cst.2019.04.024 [11] 孙振敏. 穿层割缝钻孔对煤体卸压增透效应的研究与应用[J]. 矿业安全与环保,2019,46(5):75-79,84. doi: 10.3969/j.issn.1008-4495.2019.05.016SUN Zhenmin. Research and application of pressure relived and permeability enhanced effect of perforated slotting borehole on coal[J]. Mining Safety & Environmental Protection,2019,46(5):75-79,84. doi: 10.3969/j.issn.1008-4495.2019.05.016 [12] 陈洪涛,李太训. 薛湖煤矿超高压水力割缝工艺参数优化试验[J]. 工矿自动化,2020,46(1):90-94. doi: 10.13272/j.issn.1671-251x.2019060067CHEN Hongtao,LI Taixun. Optimization test of ultra-high pressure hydraulic slotting process parameters in Xuehu Coal Mine[J]. Industry and Mine Automation,2020,46(1):90-94. doi: 10.13272/j.issn.1671-251x.2019060067 [13] 陈树亮,黄炳香,李丁,等. 煤岩体高压磨料水力割缝基本规律的试验研究[J]. 采矿与岩层控制工程学报,2020,2(4):90-96.CHEN Shuliang,HUANG Bingxiang,LI Ding,et al. Experiment study on the basic law of high pressure abrasive hydraulic cutting for coal-rock mass[J]. Journal of Mining and Strata Control Engineering,2020,2(4):90-96. [14] 李生舟,乔伟,王建. 深部突出煤层超高压水射流割缝工艺参数研究与应用[J]. 矿业安全与环保,2020,47(4):57-61. doi: 10.19835/j.issn.1008-4495.2020.04.011LI Shengzhou,QIAO Wei,WANG Jian. Research and application of technological parameters of ultra-high pressure water jet slotting in deep outburst coal seam[J]. Mining Safety & Environmental Protection,2020,47(4):57-61. doi: 10.19835/j.issn.1008-4495.2020.04.011 [15] 陆占金,李生舟. 赵固二矿坚硬煤层超高压水力割缝增透技术应用[J]. 煤炭工程,2021,53(4):76-80.LU Zhanjin,LI Shengzhou. Application of super-high pressure hydraulic slotting for permeability enhancing in hard coal seam of Zhaogu No.2 Mine[J]. Coal Engineering,2021,53(4):76-80. [16] 倪兴. 叠加效应下多孔水力割缝联合抽采参数优化研究[J]. 工矿自动化,2023,49(1):146-152. doi: 10.13272/j.issn.1671-251x.2022060110NI Xing. Optimization of multi-hole hydraulic cutting combined extraction parameters under superposition effect[J]. Journal of Mine Automation,2023,49(1):146-152. doi: 10.13272/j.issn.1671-251x.2022060110 [17] 鲁义,申宏敏,秦波涛,等. 顺层钻孔瓦斯抽采半径及布孔间距研究[J]. 采矿与安全工程学报,2015,32(1):156-162. doi: 10.13545/j.cnki.jmse.2015.01.025LU Yi,SHEN Hongmin,QIN Botao,et al. Gas drainage radius and borehole distance along seam[J]. Journal of Mining & Safety Engineering,2015,32(1):156-162. doi: 10.13545/j.cnki.jmse.2015.01.025 [18] 崔宝库,张根. 不同布置方式下穿层钻孔瓦斯抽采数值模拟研究[J]. 能源与环保,2020,42(8):45-49.CUI Baoku,ZHANG Gen. Numerical simulation research on gas drainage used by layer-through holes with different layouts[J]. China Energy and Environmental Protection,2020,42(8):45-49. [19] 葛兆龙,梅绪东,贾亚杰,等. 高压水射流割缝钻孔抽采影响半径研究[J]. 采矿与安全工程学报,2014,31(4):657-664. doi: 10.13545/j.issn1673-3363.2014.04.027GE Zhaolong,MEI Xudong,JIA Yajie,et al. Influence radius of slotted borehole drainage by high pressure water jet[J]. Journal of Mining & Safety Engineering,2014,31(4):657-664. doi: 10.13545/j.issn1673-3363.2014.04.027 [20] 郝富昌,孙丽娟,刘明举. 考虑卸压和抽采效果的水力冲孔布孔参数优化研究[J]. 采矿与安全工程学报,2014,31(5):756-763. doi: 10.13545/j.issn1673-3363.2014.05.015HAO Fuchang,SUN Lijuan,LIU Mingju. Research on boreholes space optimization of hydraulic flushing considering press relief and gas drainage effect[J]. Journal of Mining & Safety Engineering,2014,31(5):756-763. doi: 10.13545/j.issn1673-3363.2014.05.015 [21] 卢平,沈兆武,朱贵旺,等. 岩样应力应变全程中的渗透性表征与试验研究[J]. 中国科学技术大学学报,2002,32(6):678-684. doi: 10.3969/j.issn.0253-2778.2002.06.008LU Ping,SHEN Zhaowu,ZHU Guiwang,et al. Characterization and experimental study on the permeability of rock-samples during complete stress-strain course[J]. Journal of University of Science and Technology of China,2002,32(6):678-684. doi: 10.3969/j.issn.0253-2778.2002.06.008 [22] 张雷,周宏伟,王向宇,等. 考虑时效影响的深部煤层瓦斯运移特性[J]. 煤炭学报,2019,44(6):1771-1779. doi: 10.13225/j.cnki.jccs.2018.0820ZHANG Lei,ZHOU Hongwei,WANG Xiangyu,et al. Characteristics of deep coalbed gas migration based on the time-dependent effect[J]. Journal of China Coal Society,2019,44(6):1771-1779. doi: 10.13225/j.cnki.jccs.2018.0820 [23] XIE Shengrong, CUI Junqi, CHEN Dongdong, et al. Numerical simulation study on gas drainage by interval hydraulic flushing in coal seam working face[J]. Energy Exploration & Exploitation, 2021, 39(4): 1123-1142. [24] 褚廷湘,李品,晁江坤,等. 承压破碎煤体碎胀系数演变特征与机制[J]. 煤炭学报,2017,42(12):3182-3188.CHU Tingxiang,LI Pin,CHAO Jiangkun,et al. Bulking coefficient evolution characteristics and mechanism of compacted broken coal[J]. Journal of China Coal Society,2017,42(12):3182-3188. -

下载:

下载: