Optimization of multi-hole hydraulic cutting combined extraction parameters under superposition effect

-

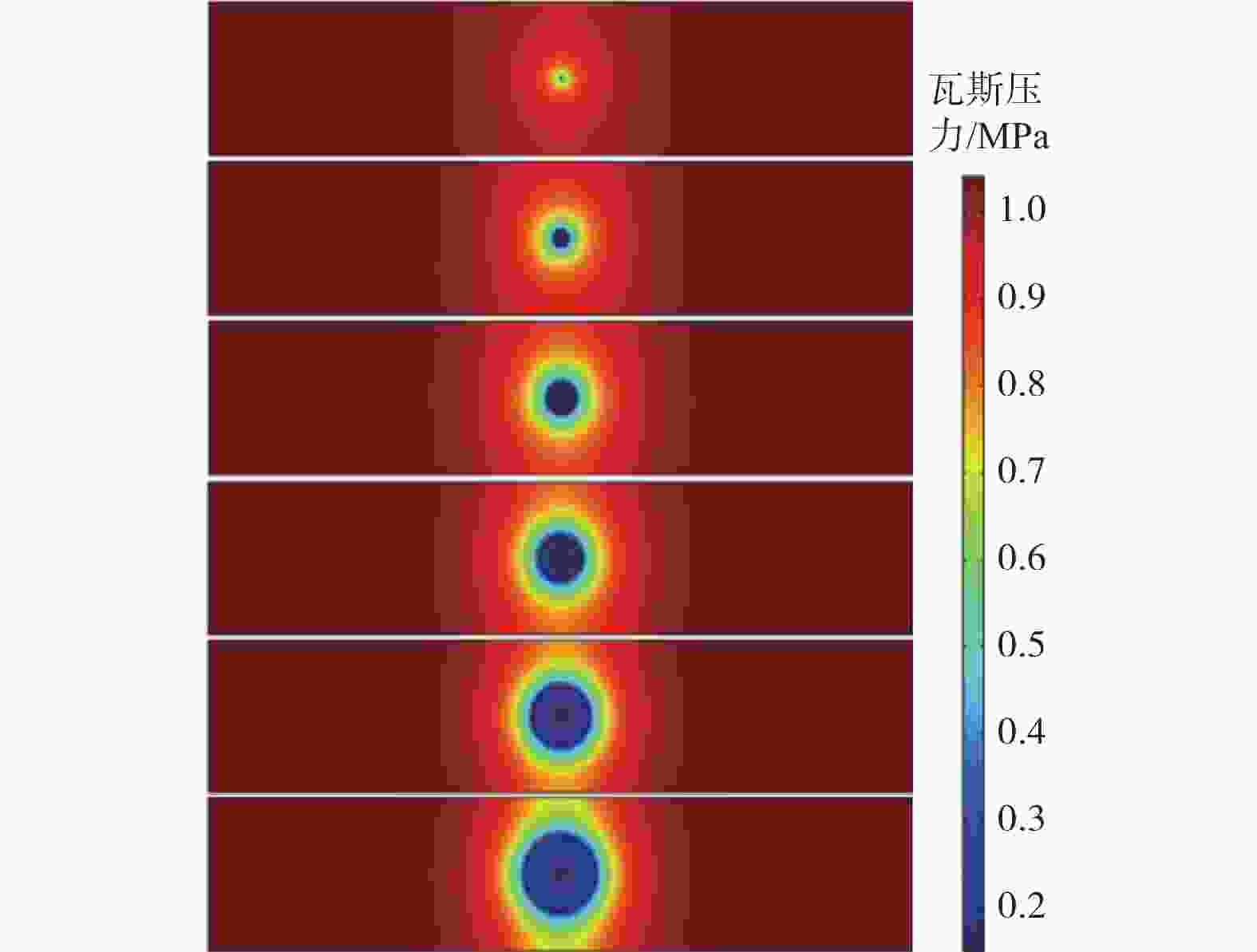

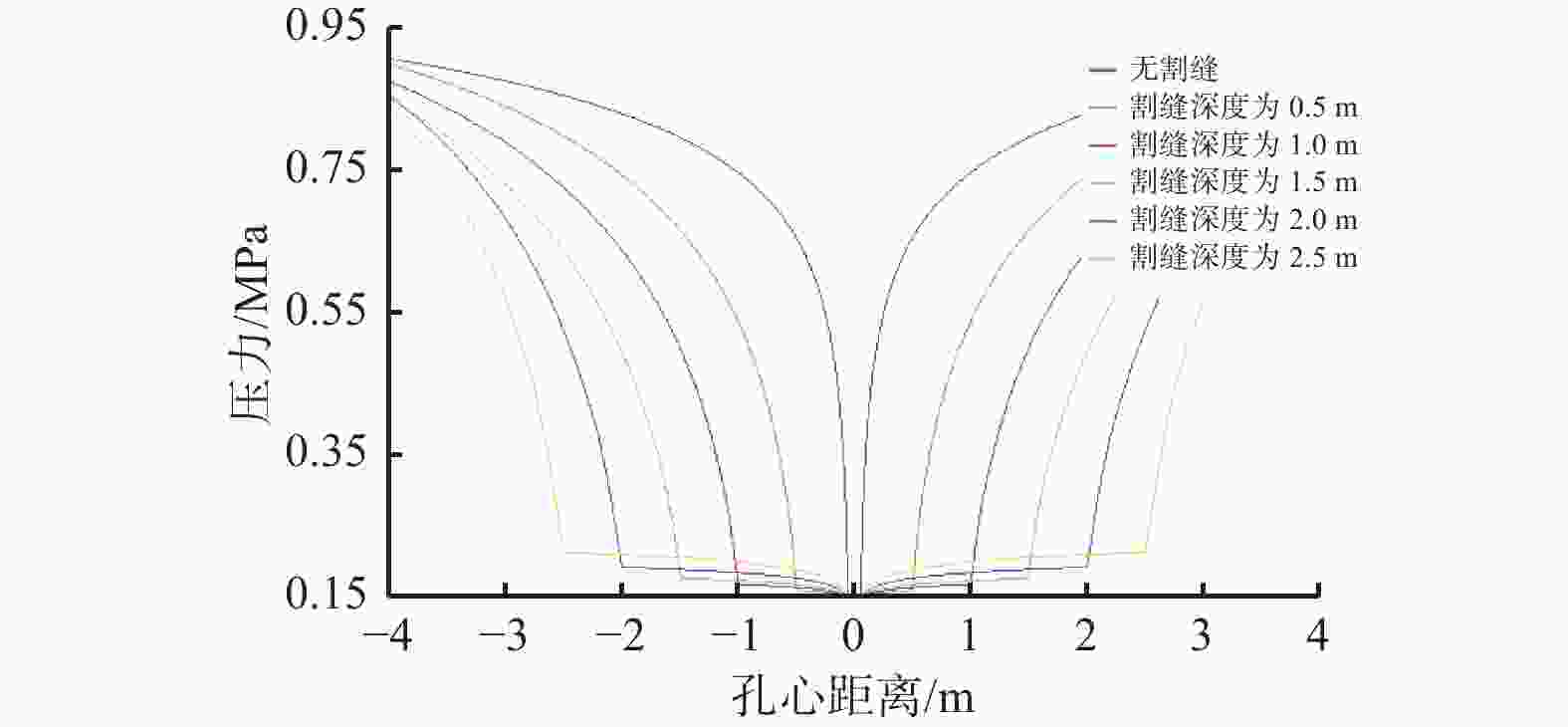

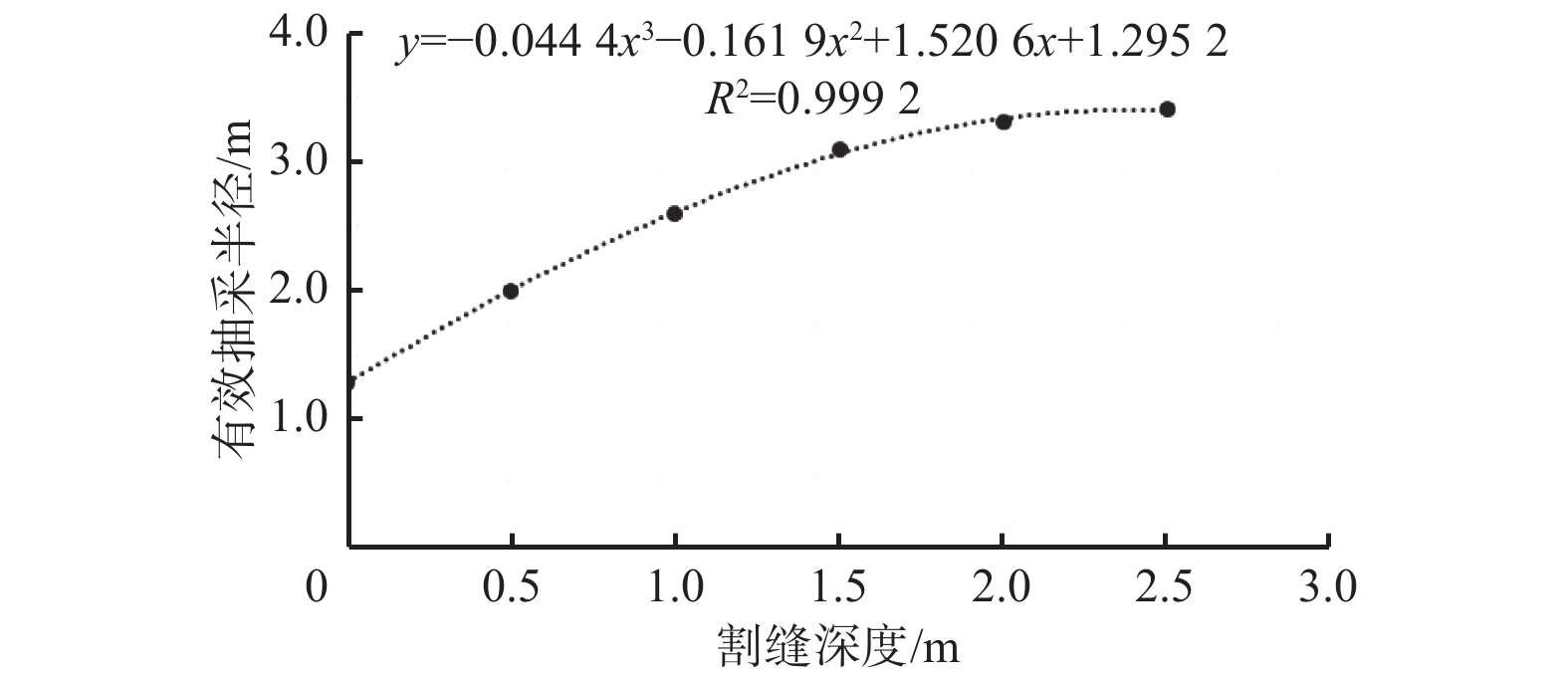

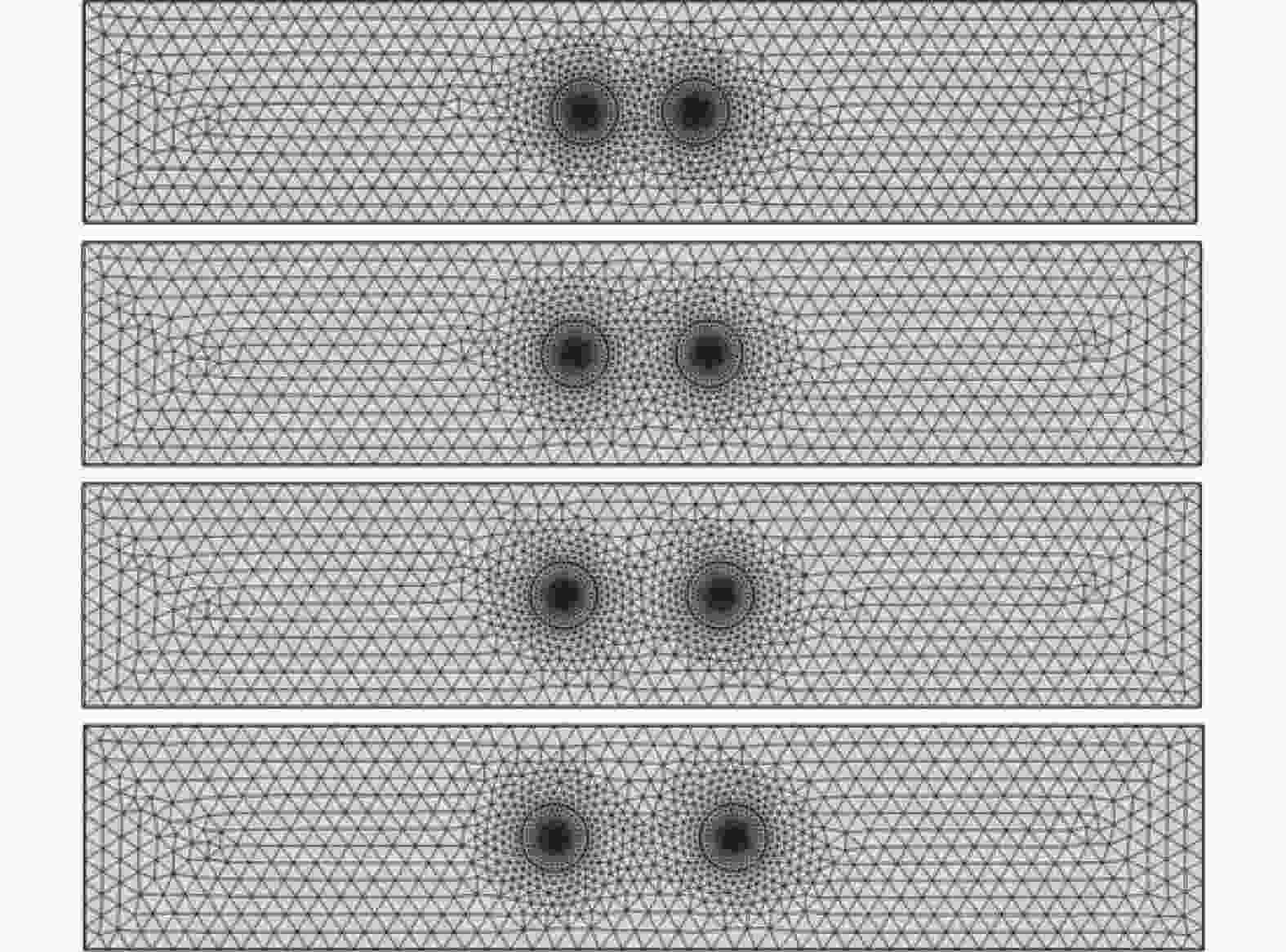

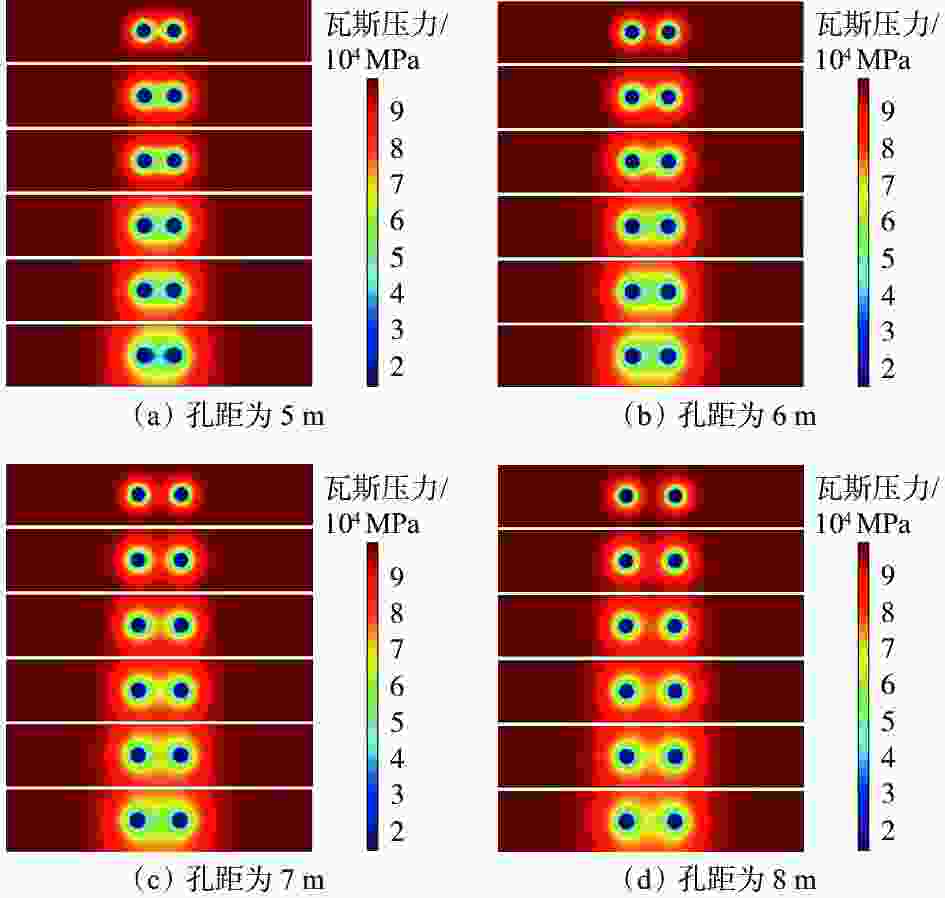

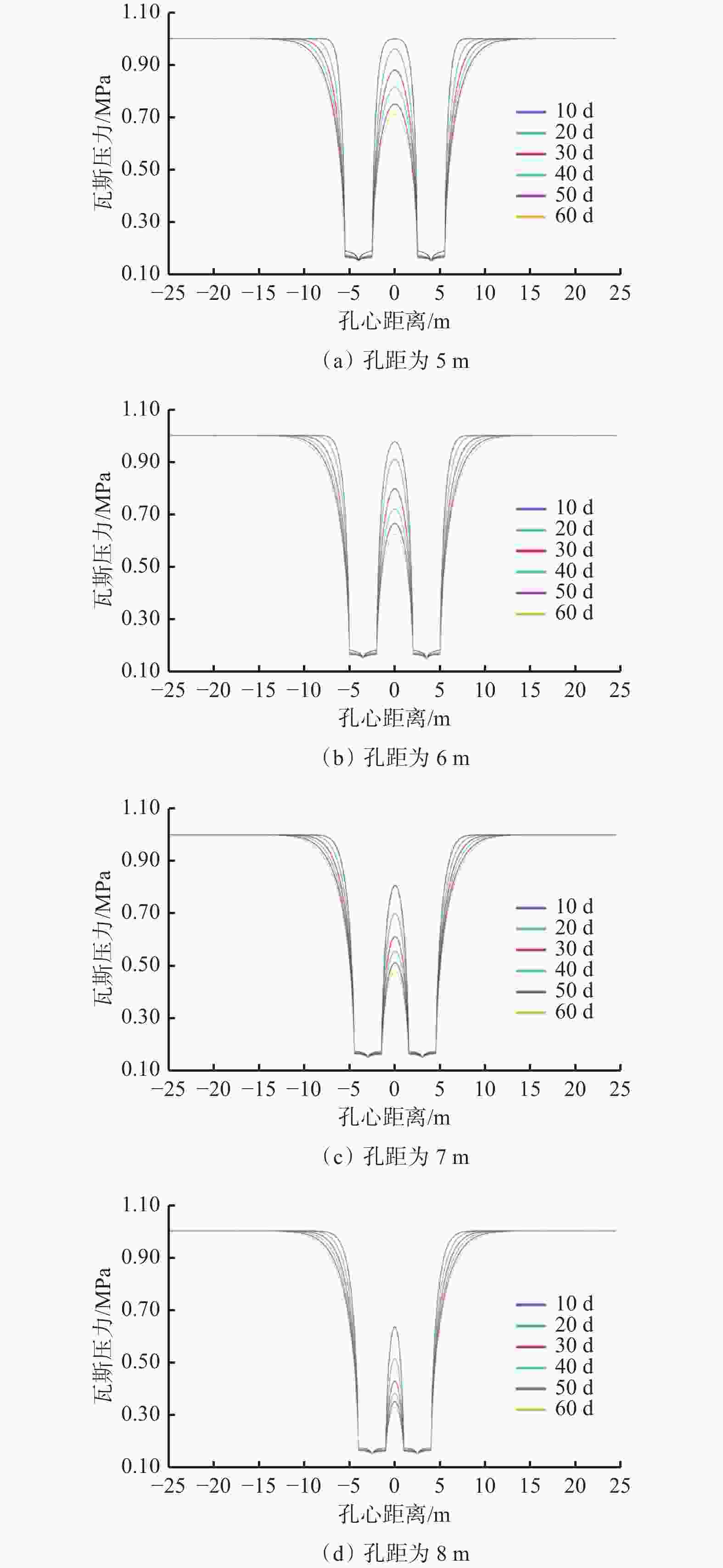

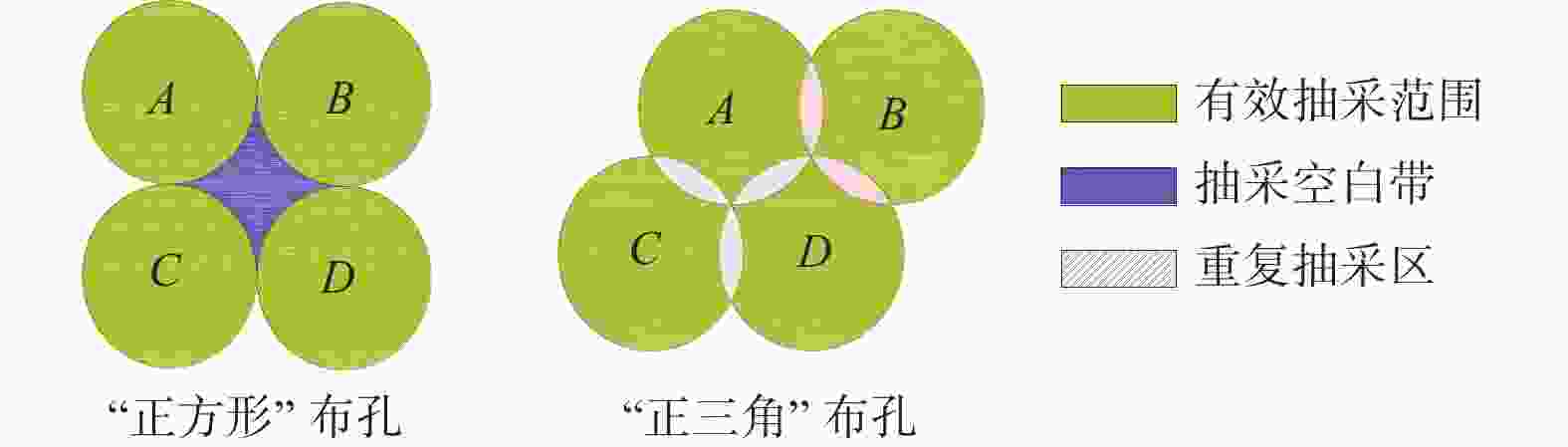

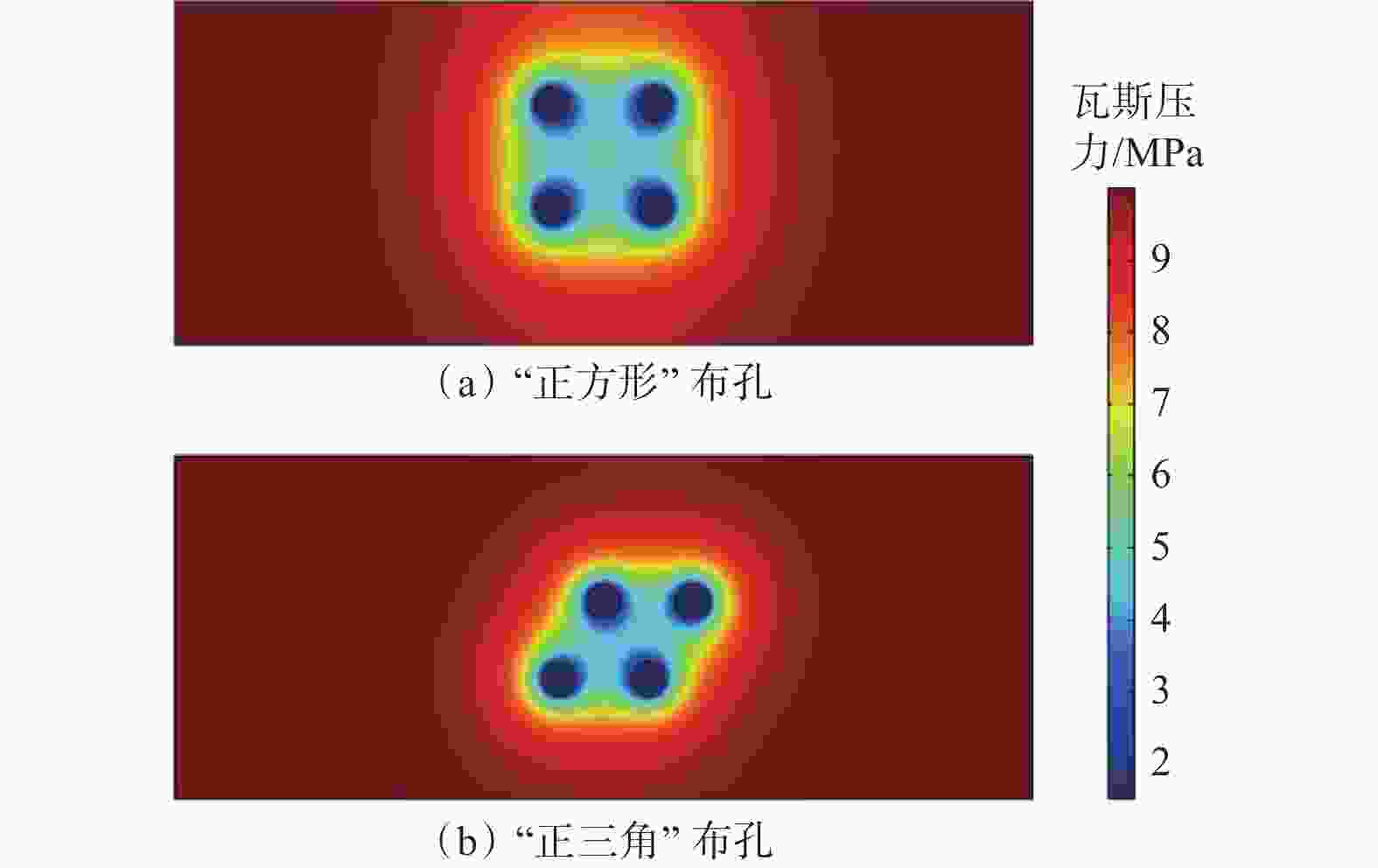

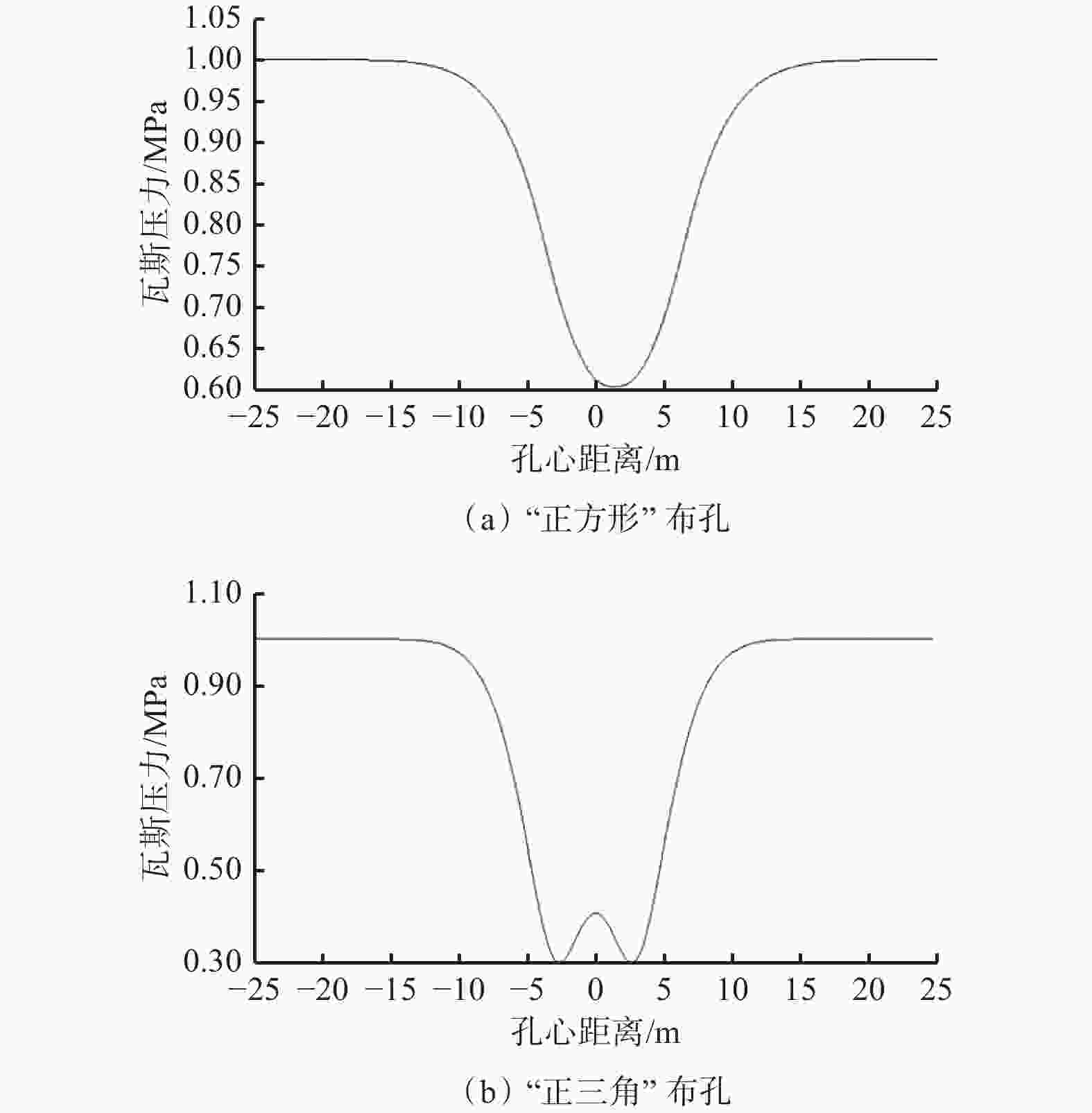

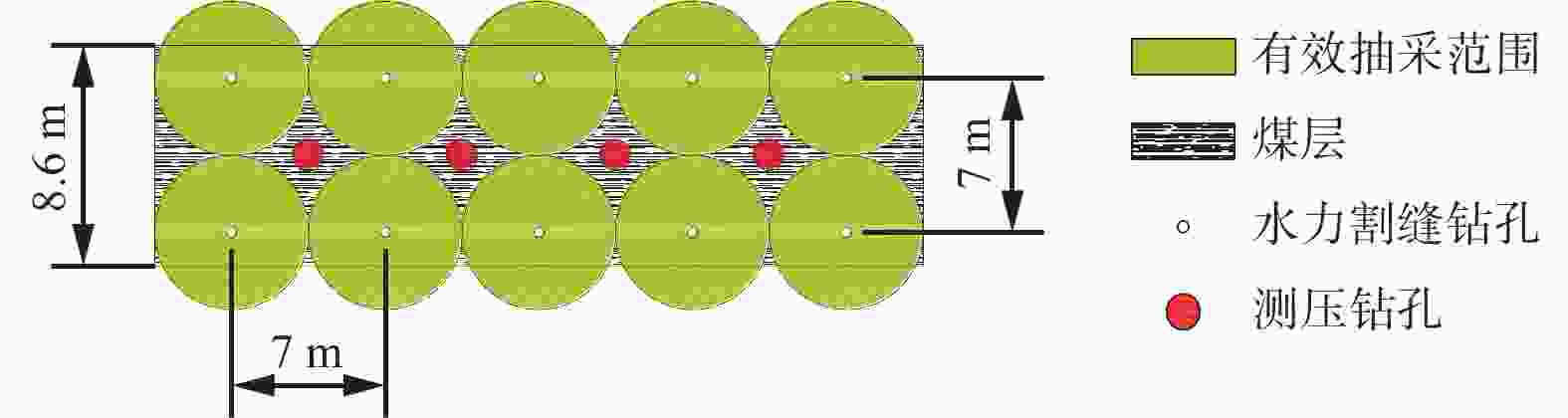

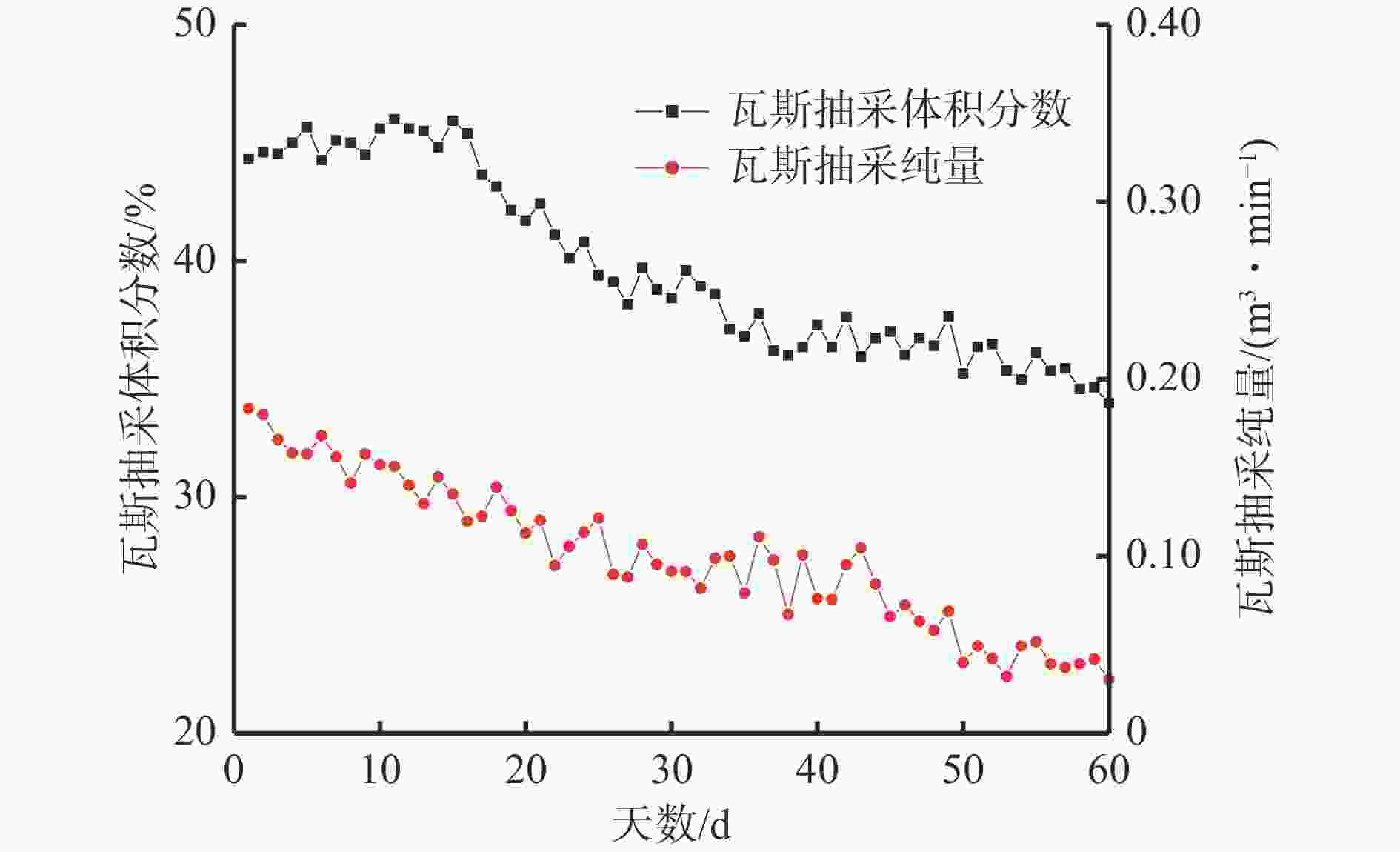

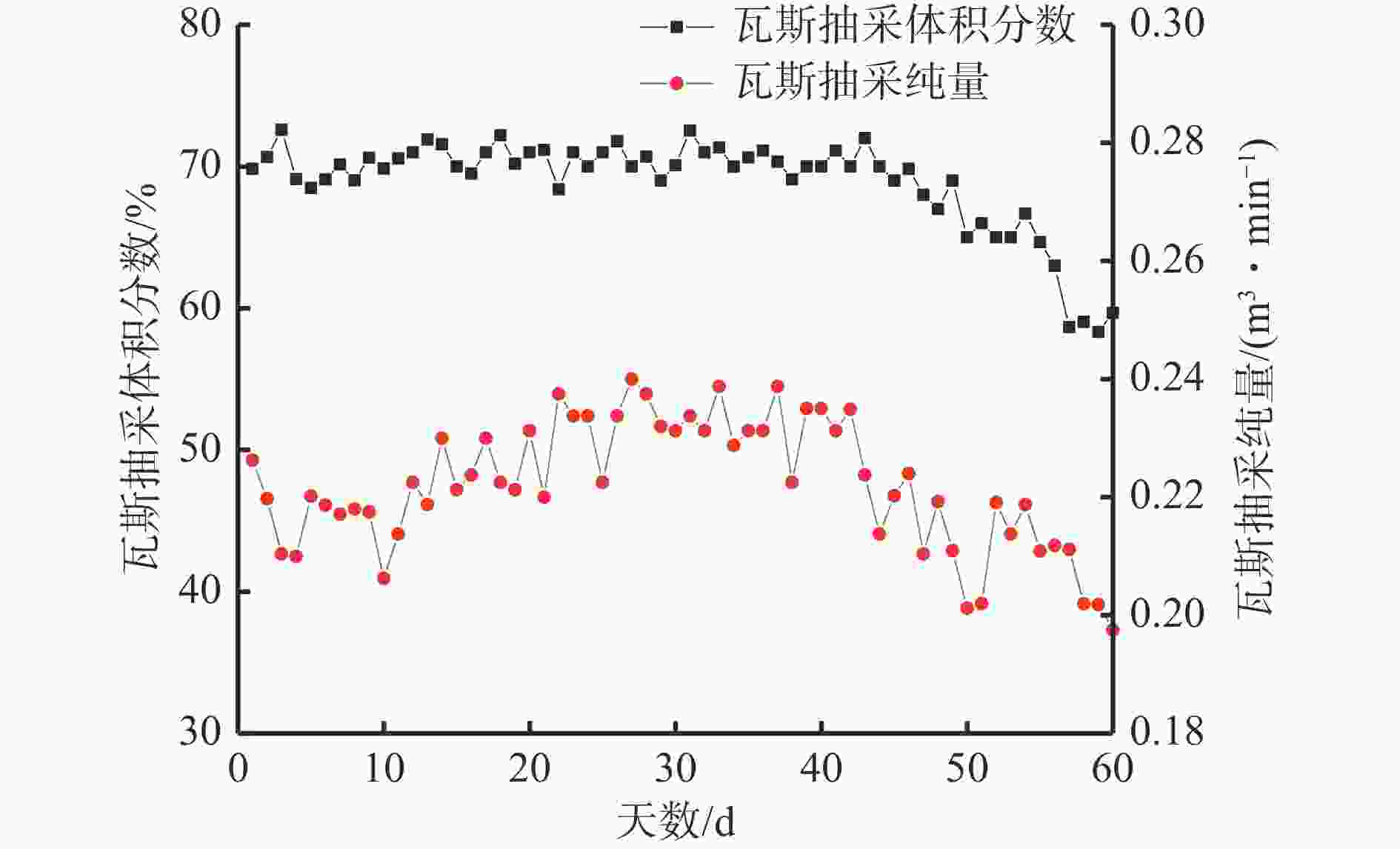

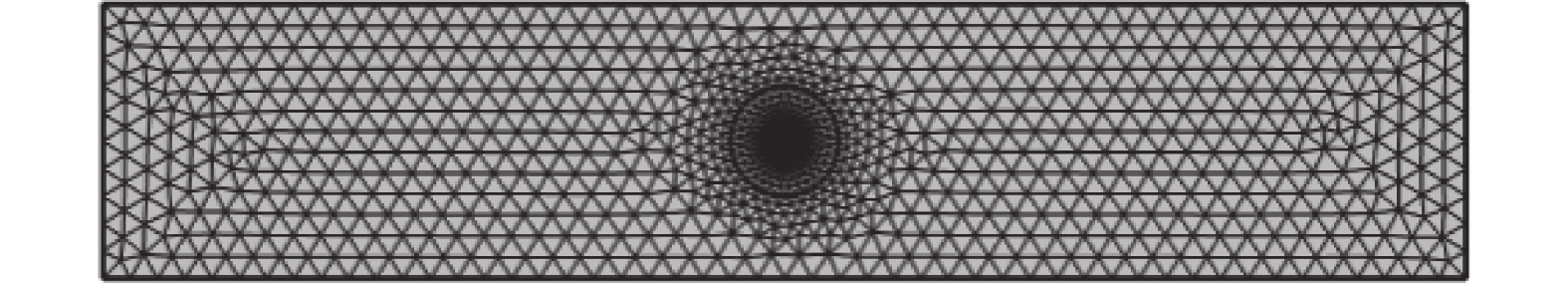

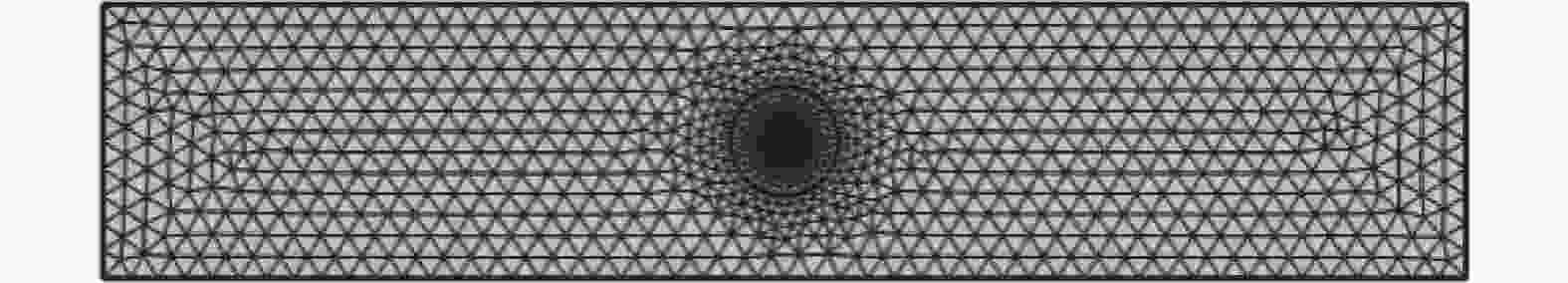

摘要: 针对低透高瓦斯煤层在水力割缝过程中存在割缝扰动范围不清、割缝钻孔最佳布孔间距不明确的问题,以贵州豫能高山煤矿1908工作面为研究背景,在建立水力割缝煤体瓦斯抽采流固耦合模型的基础上,借助COMSOL数值模拟软件对高山煤矿1908工作面水力割缝钻孔有效抽采半径、孔周瓦斯压力变化情况进行了研究,并依据模拟结果深入分析了水力割缝钻孔在多孔布置时,受孔间抽采叠加效应影响下有效抽采范围及孔间瓦斯压力变化情况,最终得出其最佳布孔间距及抽采时间。结果表明:① 水力割缝钻孔单孔抽采效果随割缝深度显著提升,但钻孔有效抽采半径增速变缓,为得到最佳割缝深度,对各钻孔有效抽采半径进行三项式拟合,随着水力割缝深度的增加,有效抽采半径范围在快速增加后放缓且最终趋于平稳,并得出了高山煤矿最佳割缝深度为1.5 m,有效抽采半径达为3.1 m。② 在相同抽采时间下,煤体内瓦斯压力随两孔距的缩短而降低,说明孔间距越小,孔间受水力割缝所造成的扰动越剧烈,抽采叠加效应影响越显著。③ 在保证消突达标的前提下,选择孔距为7 m进行水力割缝钻孔布置效果最佳。④ 原本在“正方形”布孔方式中,孔心位置可能出现抽采盲区的点最大瓦斯压力仅为0.67 MPa,小于临界值,“正方形”布孔较“正三角”布孔的有效覆盖面积更大且减少了抽采重复区域,从而减少了钻孔施工量,提高了瓦斯治理效率。⑤ 通过现场试验得出在60 d抽采周期内,水力割缝钻孔布置采用孔距为7 m的“正方形”布孔可有效提高瓦斯抽采浓度及抽采纯量,并达到了延长高效抽采周期的效果,且可消除孔间煤体瓦斯抽采空白带,实现孔间区域煤体消突达标。Abstract: In the process of hydraulic cutting in low permeability and high gas coal seams, there are problems such as unclear cutting disturbance range and unclear optimal hole spacing for cutting drilling. In order to solve the above problems, the 1908 working face of Gaoshan Coal Mine in Yuneng, Guizhou Province is taken as the research background. On the basis of establishing the fluid-solid coupling model of gas extraction in coal body with hydraulic cutting, with the help of COMSOL numerical simulation software, the effective extraction radius of hydraulic cutting borehole and the change of gas pressure around the borehole in the 1908 working face of Gaoshan Coal Mine are studied. Based on the simulation results, the effective extraction range and gas pressure change between holes are analyzed under the influence of the extraction superposition effect between holes when the hydraulic cutting drilling holes are arranged in multiple holes. Finally, the optimal hole spacing and extraction time are obtained. The results show the following points. ① The single hole extraction effect of hydraulic cutting drilling is significantly improved with the cutting depth. However, the effective extraction radius of the borehole increases slowly. In order to obtain the best cutting depth, the effective extraction radius of each borehole is fitted in a trinomial way. With the increase of hydraulic cutting depth, the range of effective extraction radius slows down after rapid increase and finally tends to be stable. The optimal cutting depth of Gaoshan Coal Mine is 1.5 m, and the effective extraction radius is 3.1 m. ② Under the same extraction time, the gas pressure in the coal body decreases with the shortening of the distance between two holes. It shows that the smaller the hole spacing is, the more serious the disturbance caused by hydraulic cutting between holes is, and the more significant the influence of the extraction superposition effect is. ③ On the premise of ensuring that the outburst elimination meets the standard, it is best to choose a hole spacing of 7 m for arranging hydraulic cutting drilling. ④ Originally, in the "square" hole arrangement, the maximum gas pressure at the point where the blind area may occur at the hole center is only 0.67 MPa, which is less than the critical value. The effective coverage area of the "square" hole arrangement is larger than that of the "triangle" hole arrangement, and the repeated area of drainage is reduced. This reduces the amount of drilling and improves the efficiency of gas control. ⑤ Through field test, it is concluded that in the 60 d extraction period, the hydraulic cutting drilling arrangement with a hole spacing of 7 m and a "square" hole arrangement can effectively improve the concentration and purity of gas extraction. It can also extend the period of high efficiency extraction. It can eliminate the blank zone of gas extraction in the coal body between boreholes to eliminate the outburst of the coal body in the area between boreholes.

-

表 1 数值模拟基础参数

Table 1. Numerical simulation of the basic parameters

参数 参数值 煤层初始瓦斯压力/MPa 1.04 孔隙率 0.048 煤体初始渗透率/m2 5.7×10−15 割裂煤体渗透率/m2 3.4×10−11 煤密度/(kg·m−3) 1 492 瓦斯密度/(kg·m−3) 0.719 泊松比 0.29 黏聚力/MPa 0.92 瓦斯动力黏度/(Pa·s) 1.71×10−5 空气动力黏度/(Pa·s) 1.07×10−5 表 2 试验测点残余瓦斯压力、瓦斯含量

Table 2. Residual gas pressure and gas content of test measuring points

孔号 残余瓦斯压力/MPa 残余瓦斯含量/(m3·t−1) 抽采率/% 1 0.61 2.7 62.50 2 0.57 3.3 54.17 3 0.59 3.1 57.04 4 0.62 2.9 59.72 -

[1] 荆俊杰,于丽雅,延婧. 高瓦斯低渗煤层水力造穴增透技术优化研究[J]. 煤矿安全,2022,53(1):8-14,23.JING Junjie,YU Liya,YAN Jing. Research on optimization of hydraulic flushing and permeability enhancement technology in high gas and low permeability coal seam[J]. Safety in Coal Mines,2022,53(1):8-14,23. [2] 袁亮,林柏泉,杨威. 我国煤矿水力化技术瓦斯治理研究进展及发展方向[J]. 煤炭科学技术,2015,43(1):45-49. doi: 10.13199/j.cnki.cst.2015.01.011YUAN Liang,LIN Baiquan,YANG Wei. Research progress and development direction of gas control with mine hydraulic technology in China coal mine[J]. Coal Science and Technology,2015,43(1):45-49. doi: 10.13199/j.cnki.cst.2015.01.011 [3] 许克南,王佰顺,刘青宏. 基于动态流固耦合模型的瓦斯 抽采半径及孔间距研究[J]. 煤炭科学术,2018,46(5):102-108.XU Kenan,WANG Baishun,LIU Qinghong. Study on gas drainage radius and distance between boreholes based on dynamic fluid-solid coupling model[J]. Coal Science and Technology,2018,46(5):102-108. [4] 杜金磊,张民波,张电吉,等. 低透气突出煤层水力割缝协同卸压增透技术[J]. 工矿自动化,2021,47(7):98-105. doi: 10.13272/j.issn.1671-251x.17698DU Jinlei,ZHANG Minbo,ZHANG Dianji,et al. Hydraulic cutting cooperative pressure relief and premeability enhancement technology in low permeability outburst coal seam[J]. Industry and Mine Automation,2021,47(7):98-105. doi: 10.13272/j.issn.1671-251x.17698 [5] 刘生龙,朱传杰,林柏泉,等. 水力割缝空间分布模式对煤层卸压增透的作用规律[J]. 采矿与安全工程学报,2020,37(5):983-990. doi: 10.13545/j.cnki.jmse.2020.05.015LIU Shenglong,ZHU Chuanjie,LIN Baiquan,et al. The effect of spatial distribution mode of hydraulic slotting on pressure relief and permeability enhancement of the coal seam[J]. Journal of Mining & Safety Engineering,2020,37(5):983-990. doi: 10.13545/j.cnki.jmse.2020.05.015 [6] 孙鑫,王海东,路丽刚. 煤层水力割缝转速对切割半径影 响规律研究[J]. 煤炭工程,2020,52(5):116-120.SUN Xin,WANG Haidong,LU Ligang. Research on the influence of coal seam hydraulic cutting speed on cutting radius[J]. Coal Engineering,2020,52(5):116-120. [7] 袁本庆. 煤巷条带水力化增透技术措施适用条件及评价指标初探[J]. 煤矿安全,2018,49(12):164-168. doi: 10.13347/j.cnki.mkaq.2018.12.042YUAN Benqing. Application conditions and evaluation indexes of hydraulic permeability enhancement technology in coal roadway strip mining[J]. Safety in Coal Mines,2018,49(12):164-168. doi: 10.13347/j.cnki.mkaq.2018.12.042 [8] 林柏泉,赵洋,刘厅,等. 水力割缝煤体多场耦合响应规律研究[J]. 西安科技大学学报,2017,37(5):662-667. doi: 10.13800/j.cnki.xakjdxxb.2017.0510LIN Baiquan,ZHAO Yang,LIU Ting,et al. Coupling response law of multi-field in coal seam after hydraulic slotting[J]. Journal of Xi'an University of Science and Technology,2017,37(5):662-667. doi: 10.13800/j.cnki.xakjdxxb.2017.0510 [9] 徐刚,张剀文,范亚飞. 叠加效应影响下钻孔有效抽采半径的数值模拟及布孔间距优化[J]. 矿业安全与环保,2021,48(1):91-96. doi: 10.19835/j.issn.1008-4495.2021.01.018XU Gang,ZHANG Kaiwen,FAN Yafei. Numerical simulation of effective drainage radius and optimization of hole spacing under the influence of stack effect[J]. Mining Safety & Environmental Protection,2021,48(1):91-96. doi: 10.19835/j.issn.1008-4495.2021.01.018 [10] ZHANG Hongbin,LIU Jishan,ELSWORTH D. How sorption-induced matrix deformation affects gas flow in coal seams:a new FE model[J]. International Journal of Rock Mechanics and Mining Sciences,2008,45(8):1226-1236. doi: 10.1016/j.ijrmms.2007.11.007 [11] 刘泉霖,王恩元,李忠辉,等. 夹矸对煤层瓦斯抽采影响的数值模拟研究[J]. 工矿自动化,2018,44(2):55-62. doi: 10.13272/j.issn.1671-251x.2017100046LIU Quanlin,WANG Enyuan,LI Zhonghui,et al. Numerical simulation study on influence of gangue on coal seam gas drainage[J]. Industry and Mine Automation,2018,44(2):55-62. doi: 10.13272/j.issn.1671-251x.2017100046 [12] 李文,王广宏,欧聪,等. 不同布孔方式下梳状定向长钻孔水力压裂数值模拟及工程应用[J]. 煤矿安全,2021,52(5):72-77. doi: 10.13347/j.cnki.mkaq.2021.05.013LI Wen,WANG Guanghong,OU Cong,et al. Numerical simulation and engineering application of comb-shaped directional long borehole hydraulic fracturing under different arrangement of holes[J]. Safety in Coal Mines,2021,52(5):72-77. doi: 10.13347/j.cnki.mkaq.2021.05.013 -

下载:

下载: