Research on key technologies of 3D laser scanning modeling in fully mechanized working face

-

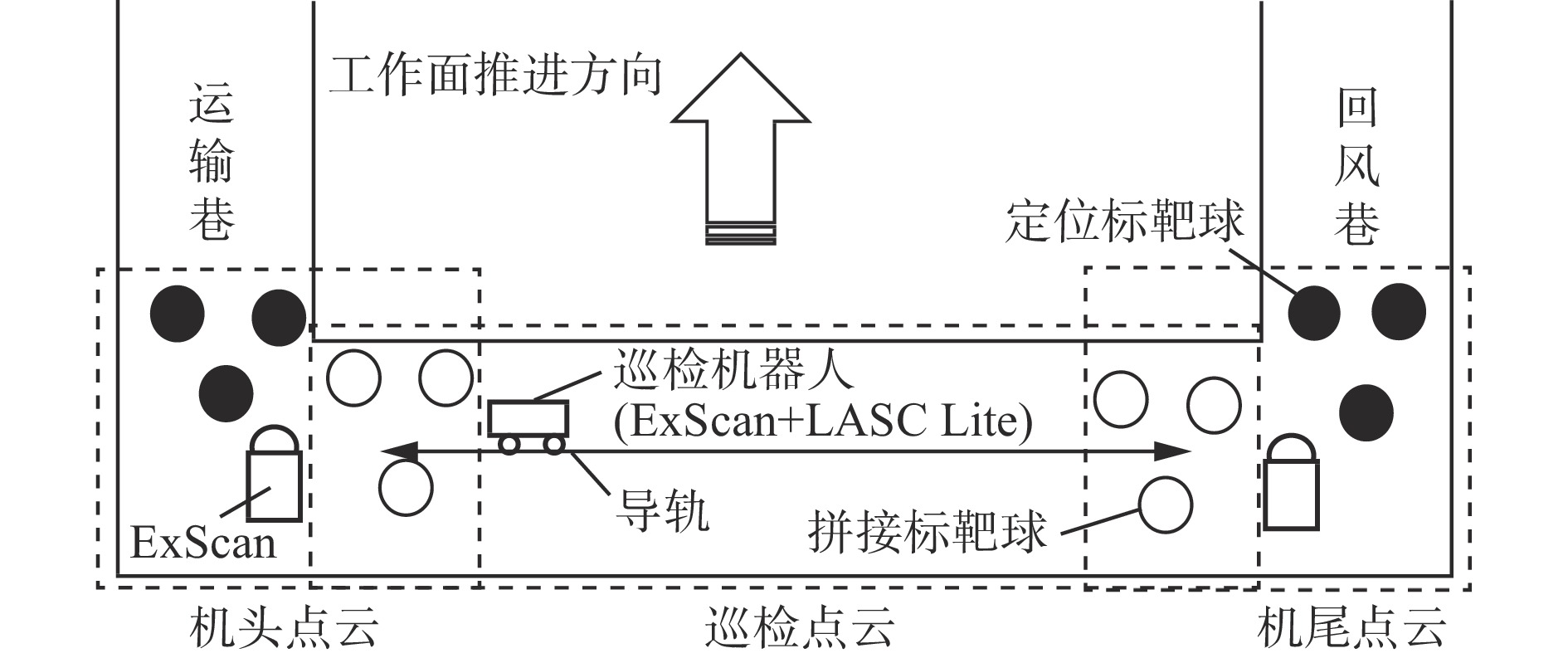

摘要: 根据综采工作面三维激光扫描模型中煤壁与顶板交线信息,采煤机可自动调整滚筒截割高度,实现煤炭精准开采。现有技术实现了基于工作面激光点云的割煤顶板线自动提取,但提取结果不能直接应用于数字化自主割煤。针对该问题,提出了综采工作面三维激光扫描建模总体方案,并对煤壁与顶板交线提取、标靶球检测、点云拼接及坐标转换等关键技术进行了研究,实现了三维地质坐标系下煤壁与顶板交线信息的近实时获取,该信息可直接发送给采煤机滚筒,为采煤机下一刀截割提供数据参考。通过巡检机器人完成工作面扫描,获取巡检点云;基于煤壁与顶板交线的曲率特性,采用弦法向量法对煤壁与顶板交线进行粗提取;引入数据点法向量与邻域点法向量的夹角信息,通过阈值排除明显的非煤壁与顶板交线点。由于巡检点云与提取的交线信息均位于局部坐标系,通过定位标靶球检测和配准,完成机头点云、机尾点云与巡检点云的拼接,得到工作面联合点云。根据定位标靶球的三维地质坐标与局部坐标,得到坐标间的转换关系,通过坐标转换将联合点云转换到三维地质坐标系下,从而得到三维地质坐标系下的煤壁与顶板交线信息。井下工业性试验结果表明,采用综采工作面三维激光扫描技术提取煤壁与顶板交线的误差在10 cm以内,所有采样点中误差小于4 cm的采样点占比为50%,误差小于8 cm的采样点占比为96.67%。Abstract: According to the boundary information of the coal wall and roof in the 3D laser scanning model of fully mechanized working face, the shearer can automatically adjust the cutting height of the drum to realize the coal precise mining. The existing technology realizes the automatic extraction of the roof line of coal cutting based on the laser point cloud of the working face. But the extraction results cannot be directly applied to the digital automatic coal cutting. In order to solve this problem, the overall scheme of 3D laser scanning modeling for fully mechanized working face is proposed. The key technologies such as boundary extraction of coal wall and roof, target ball detection, point cloud registration and coordinate transformation are studied. The near real-time acquisition of boundary information of coal wall and roof under 3D geological coordinate system is realized. The information can be directly sent to the shearer drum to provide data reference for the next cutting of the shearer. The scanning of the working surface is realized through an inspection robot to obtain the inspection point cloud. Based on the curvature characteristics of the boundary of the coal wall and roof, the string and normal vector method is used to extract the boundary of the coal wall and roof roughly. The angle information between the normal vector of data points and the normal vector of adjacent points is introduced. The obvious intersection points of non coal wall and roof are eliminated through the threshold. As the inspection point cloud and the extracted boundary information are both located in a local coordinate system, the head and tail point clouds and the inspection point cloud are registered through the detection and registration of the positioning target ball. The working face combined point cloud is obtained. According to the 3D geological coordinate and the local coordinate of the positioning target ball, the transformation relation between the coordinates is obtained. The combined point cloud is transformed into the 3D geological coordinate system through coordinate transformation. Therefore, the boundary information of the coal wall and the roof under the 3D geological coordinate system is obtained. The underground industrial test results show that the error of the boundary between the coal wall and roof extracted by 3D laser scanning technology in fully mechanized working face is less than 10 cm. The sampling points with error less than 4 cm account for 50%. The sampling points with error less than 8 cm account for 96.67%.

-

表 1 不同技术方案下煤壁与顶板交线提取结果对比

Table 1. Comparison of extraction results of coal wall and roof boundary under different technical schemes

技术方案 占比/% 误差小于4 cm 误差小于8 cm 文献[10]方案 84 96 本文方案 50 96.67 -

[1] 王国法,刘峰,孟祥军,等. 煤矿智能化(初级阶段)研究与实践[J]. 煤炭科学技术,2019,47(8):1-36. doi: 10.13199/j.cnki.cst.2019.08.001WANG Guofa,LIU Feng,MENG Xiangjun,et al. Research and practice on intelligent coal mine construction(primary stage)[J]. Coal Science and Technology,2019,47(8):1-36. doi: 10.13199/j.cnki.cst.2019.08.001 [2] 袁亮,张平松. 煤炭精准开采地质保障技术的发展现状及展望[J]. 煤炭学报,2019,44(8):2277-2284. doi: 10.13225/j.cnki.jccs.KJ19.0571YUAN Liang,ZHANG Pingsong. Development status and prospect of geological guarantee technology for precise coal mining[J]. Journal of China Coal Society,2019,44(8):2277-2284. doi: 10.13225/j.cnki.jccs.KJ19.0571 [3] 李首滨. 智能化开采研究进展与发展趋势[J]. 煤炭科学技术,2019,47(10):102-110. doi: 10.13199/j.cnki.cst.2019.10.012LI Shoubin. Progress and development trend of intelligent mining technology[J]. Coal Science and Technology,2019,47(10):102-110. doi: 10.13199/j.cnki.cst.2019.10.012 [4] 刘晓阳,胡乔森,李慧娟. 基于三维激光扫描技术的巷道顶板监测研究[J]. 中国煤炭,2017,43(7):81-84,107. doi: 10.3969/j.issn.1006-530X.2017.07.021LIU Xiaoyang,HU Qiaosen,LI Huijuan. Research on coal mine roof monitoring based on three-dimensional laser scanning technology[J]. China Coal,2017,43(7):81-84,107. doi: 10.3969/j.issn.1006-530X.2017.07.021 [5] DUNN M,REID P,MALOS J. Development of a protective enclosure for remote sensing applications—case study:laser scanning in underground coal mines[J]. Resources,2020,9(5):1-10. [6] 原长锁,王峰. 综采工作面透明化开采模式及关键技术[J]. 工矿自动化,2022,48(3):11-15,31. doi: 10.13272/j.issn.1671-251x.2021110048YUAN Changsuo,WANG Feng. Transparent mining mode and key technologies of fully mechanized working face[J]. Journal of Mine Automation,2022,48(3):11-15,31. doi: 10.13272/j.issn.1671-251x.2021110048 [7] 王国法,杜毅博. 智慧煤矿与智能化开采技术的发展方向[J]. 煤炭科学技术,2019,47(1):1-10. doi: 10.13199/j.cnki.cst.2019.01.001WANG Guofa,DU Yibo. Development direction of intelligent coal mine and intelligent mining technology[J]. Coal Science and Technology,2019,47(1):1-10. doi: 10.13199/j.cnki.cst.2019.01.001 [8] 谷彬,赵云飞. 自主智能割煤技术在榆家梁煤矿43101综采工作面的实践应用[J]. 能源科技,2020,18(7):29-32.GU Bin,ZHAO Yunfei. Practical application of autonomous intelligent coal-cutting technology in the fully-mechanized working face 43101 of Yujialiang Coal Mine[J]. Energy Science and Technology,2020,18(7):29-32. [9] 李森,王峰,刘帅,等. 综采工作面巡检机器人关键技术研究[J]. 煤炭科学技术,2020,48(7):218-225. doi: 10.13199/j.cnki.cst.2020.07.022LI Sen,WANG Feng,LIU Shuai,et al. Study on key technology of patrol robots for fully-mechanized mining face[J]. Coal Science and Technology,2020,48(7):218-225. doi: 10.13199/j.cnki.cst.2020.07.022 [10] 姜龙飞,毛善君,李梅,等. 基于激光点云的割煤顶板线提取技术研究[J]. 煤炭科学技术,2022,50(6):286-291. doi: 10.13199/j.cnki.cst.BMC20-010JIANG Longfei,MAO Shanjun,LI Mei,et al. Research on extraction technology of coal wall and roof boundary based on laser point cloud[J]. Coal Science and Technology,2022,50(6):286-291. doi: 10.13199/j.cnki.cst.BMC20-010 [11] 张冰容. 基于特征分析的点云数据逆向建模研究[D]. 保定: 华北电力大学, 2021.ZHANG Bingrong. Research on reverse modeling of point cloud data based on feature analysis[D]. Baoding: North China Electric Power University, 2021. [12] 程旭. 复杂零件三维重建与点云配准技术研究[D]. 武汉: 华中科技大学, 2019.CHENG Xu. Research on 3D reconstruction and point cloud registration technology of complex parts[D]. Wuhan: Huazhong University of Science and Technology, 2019. [13] 李自胜. 点云数据处理与特征识别关键技术研究[D]. 成都: 西南交通大学, 2017.LI Zisheng. Studies on key technology of data processing and feature recognition in point clouds[D]. Chengdu: Southwest Jiaotong University, 2017. [14] 余汪江. 基于激光雷达的无人驾驶汽车动态障碍物检测与识别研究[D]. 哈尔滨: 哈尔滨工业大学, 2020.YU Wangjiang. Research on dynamic obstacles detection and recognition of driverless vehicles based on lidar[D]. Harbin: Harbin Institute of Technology, 2020. [15] 童子良. 空间散乱三维点云数据处理与规则曲面点云拟合[D]. 淮南: 安徽理工大学, 2021.TONG Ziliang. Spatial scattered 3D point cloud data processing and regular surface point cloud fitting[D]. Huainan: Anhui University of Science and Technology, 2021. -

下载:

下载: