Real-time 3D mapping method of fully mechanized working face based on laser SLAM

-

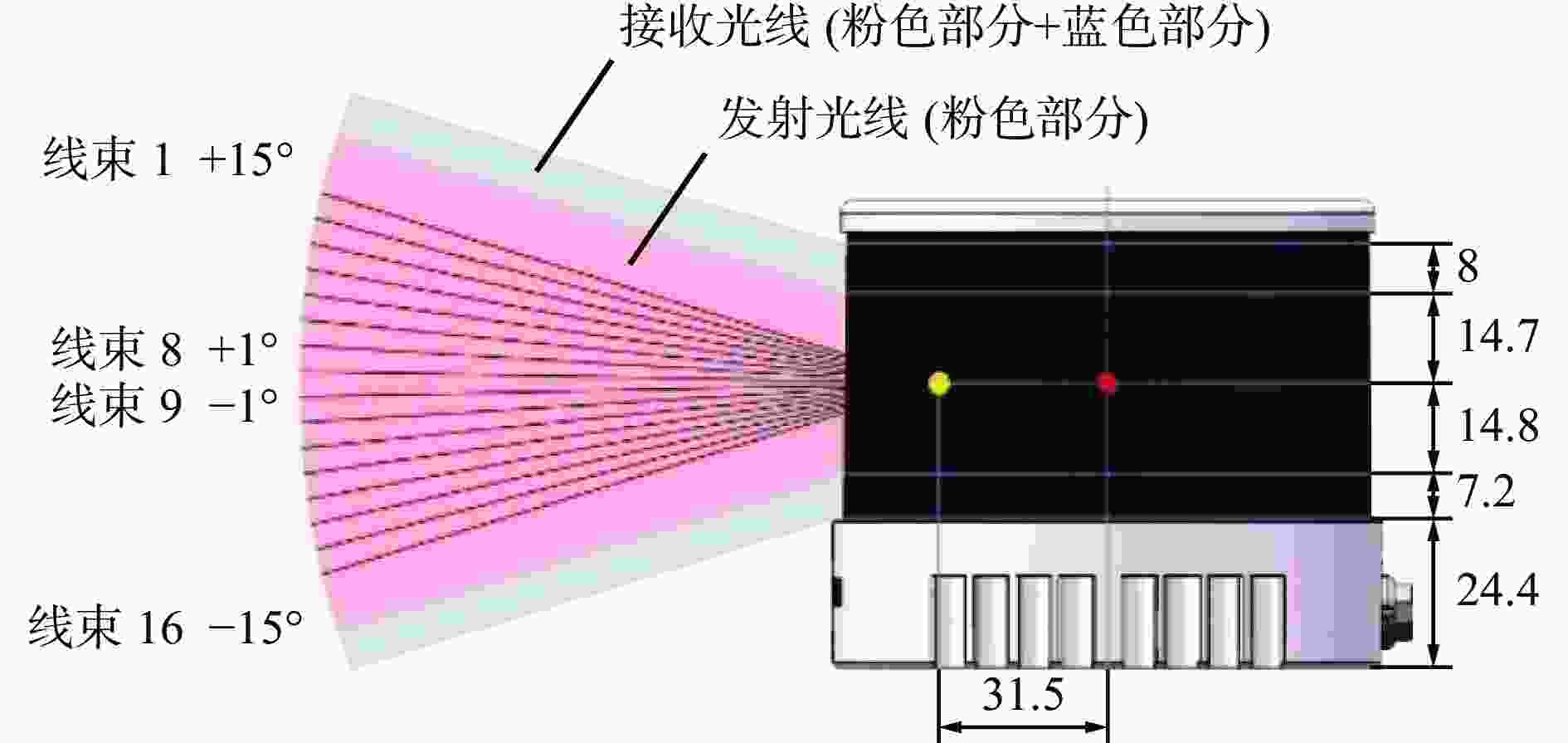

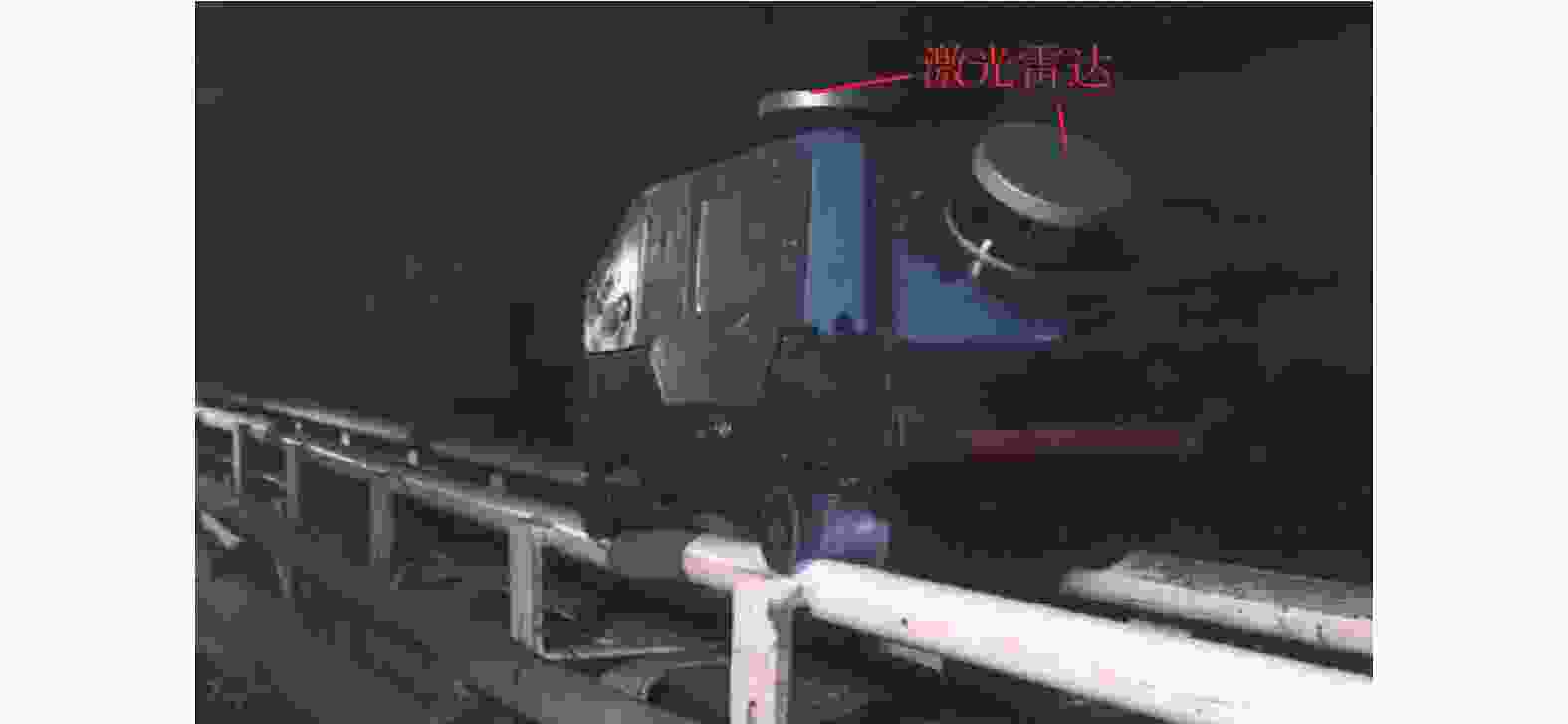

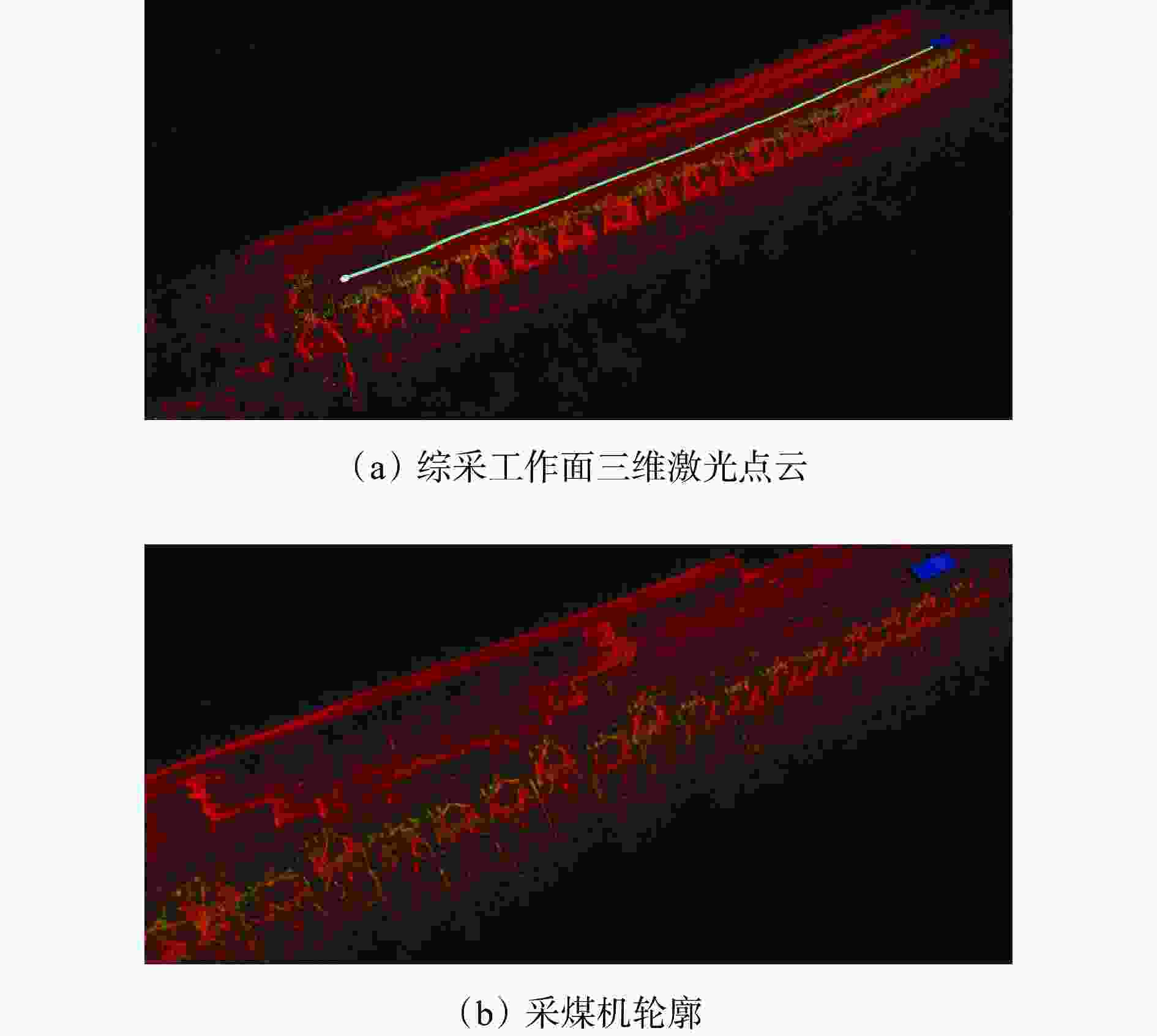

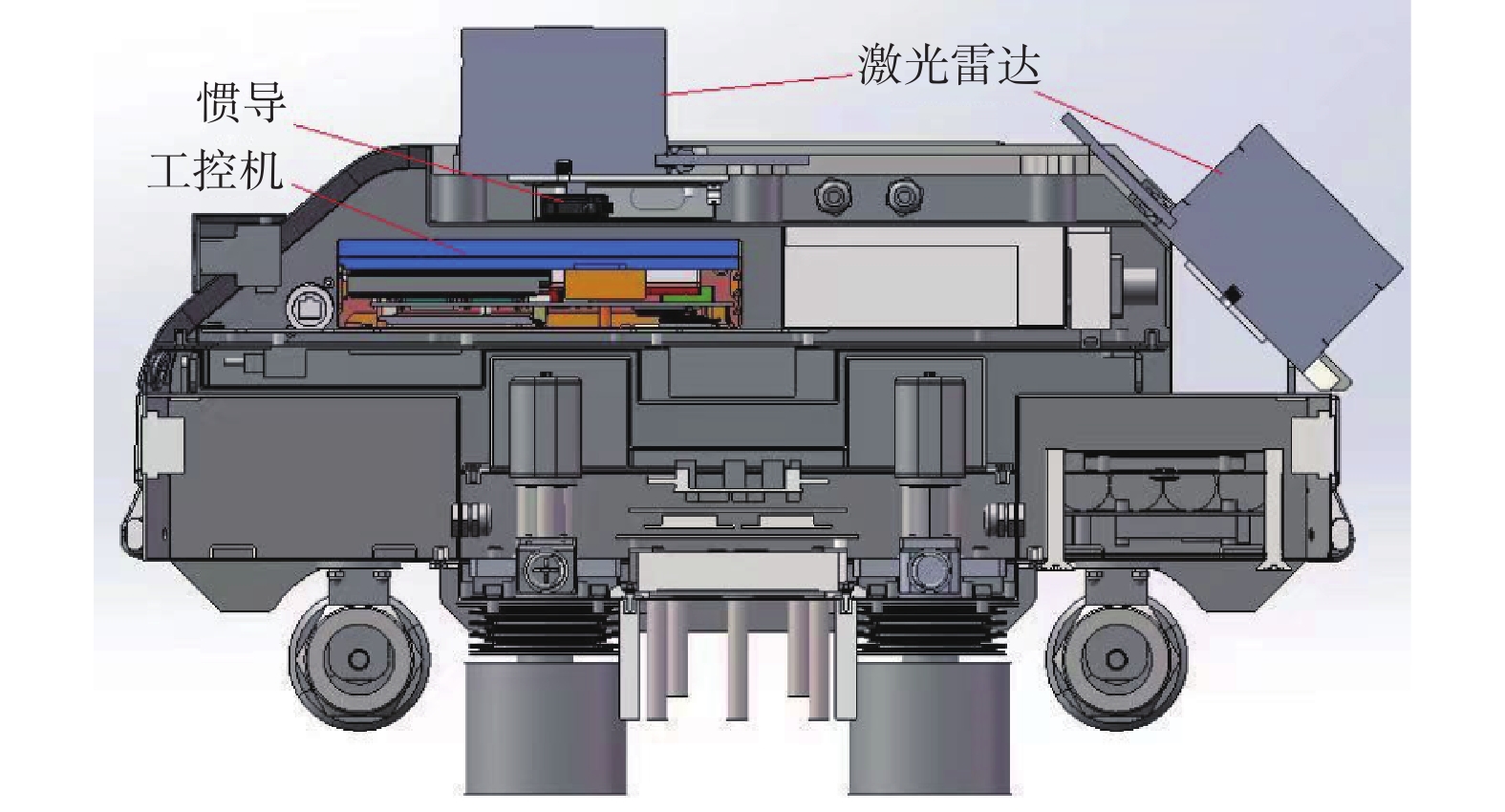

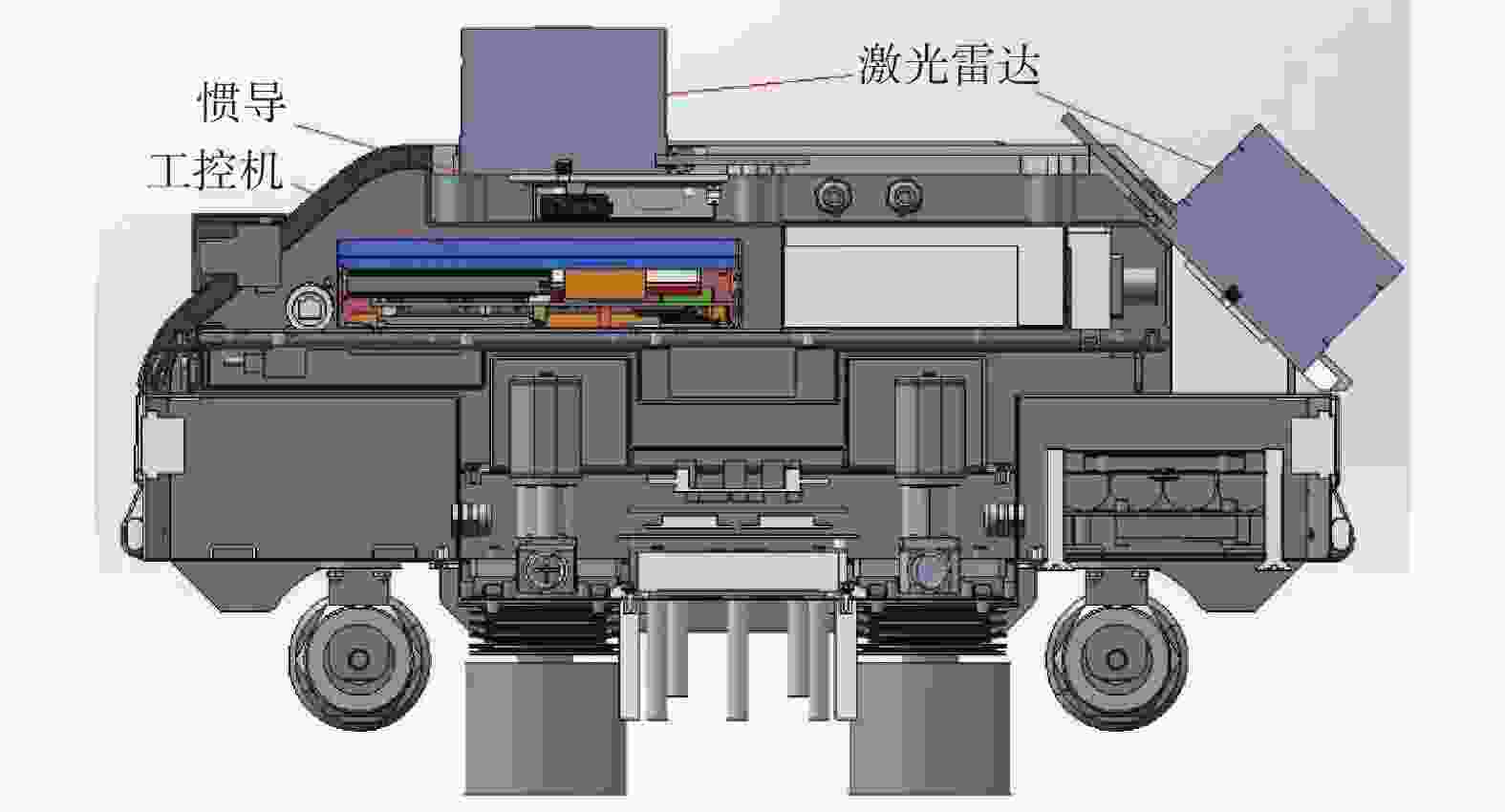

摘要: 移动式建图方法依赖高精度的光纤惯导和里程计进行位姿计算,而在实际工程实践中里程计精度难以满足应用需求,导致获取的工作面三维激光点云不完整。针对该问题,提出了一种基于激光SLAM的综采工作面实时三维建图方法。该方法主要包括激光点云去畸变、特征提取、位姿估计、优化建图等步骤。通过惯导数据消除激光点云的畸变,根据点云中每个点的时间戳检索惯导数据,获得对应每个点的姿态角,如果没有检索到对应姿态角,则采用四元数法进行插补。采用主成分分析法提取点云的几何张量特征,先求解点集的协方差矩阵,再进行特征值分解,得到几何张量特征。计算相邻2帧中特征点之间的距离,构建目标函数,采用Levenberg−Marquardt算法求解目标函数,获取变换矩阵,从而实现位姿估计。采用增量式优化算法,使用GTSAM优化库对历史关键帧与当前关键帧进行联合优化,将获得的所有关键帧点云叠加到一起,即为全局实时三维地图。井下工业性试验结果表明,该方法能实时、完整、高精度地构建全工作面范围的三维地图,最大绝对误差均值为0.19 m,满足综采工作面监控及刮板输送机找直精度需求。Abstract: The mobile mapping method relies on fiber optic inertial navigation with high precision and odometer to calculate the position and attitude. But in the actual engineering practice, the precision of odometer is difficult to meet the application requirements, resulting in incomplete 3D laser point cloud of working face. In order to solve this problem, a real-time 3D mapping method of fully mechanized working face based on laser SLAM is proposed. The method mainly comprises the steps of distortion removal of laser point cloud, feature extraction , position and attitude estimation and optimization mapping. The distortion of laser point cloud is eliminated through the inertial navigation data. The inertial navigation data is retrieved according to the time stamp of each point in the point cloud to obtain the attitude angle corresponding to each point. If the corresponding attitude angle is not retrieved, the quaternion method is adopted for interpolation. The geometric tensor feature of the point cloud is extracted by principal component analysis. Firstly, the covariance matrix of the point set is solved. Secondly, the eigenvalue decomposition is performed to obtain the geometric tensor feature. The distance between the feature points in two adjacent frames is calculated to construct an objective function. The Levenberg-Marquardt algorithm is used to solve the objective function and obtain the transformation matrix, so as to realize position and attitude estimation. The incremental optimization algorithm is adopted. The GTSAM optimization library is used for carrying out joint optimization on the historical keyframe and the current keyframe. All obtained keyframe point clouds are superposed together to obtain the global 3D real-time map. The results of the underground industrial test show that this method can construct the 3D map of the whole working face in real-time, completely and accurately. The maximum mean absolute error is 0.19 m, which meets the precision requirements of monitoring of fully mechanized working face and straightening of the scraper conveyor.

-

表 1 激光点云标记点坐标测量误差分析结果

Table 1. The error analysis result of marked points coordinate of laser point cloud

m 标记点 实测值 测量值1 测量值2 测量值3 1 (12.76,0.51,1.21) (12.77,0.42,1.27) (12.65,0.45,1.31) (12.69,0.49,1.31) 2 (30.30,0.81,1.31) (30.41,0.78,1.42) (30.55,0.89,1.50) (30.23,0.75,1.41) 3 (47.52, 1.51,1.88) (47.60, 1.32,1.83) (47.78, 1.41,1.71) (47.63, 1.41,1.92) 4 (65.77,2.52,1.23) (65.90,2.48,1.01) (65.88,2.31,1.24) (65.57,2.43,1.38) 5 (83.27,2.21,1.84) (83.42,2.41,1.69) (83.57,2.61,1.54) (83.97,2.41,1.74) 6 (101.98,2.75,1.83) (101.89,2.73,1.79) (101.92,2.77,1.79) (101.79,2.63,1.89) 7 (112.03,2.67,1.92) (112.04,2.69,1.96) (112.05,2.65,1.94) (112.06,2.68,1.95) 8 (129.53,2.69,1.90) (129.41,2.68,1.89) (129.61,2.67,1.87) (129.51,2.67,1.84) 绝对误差均值 0.18 0.19 0.14 -

[1] 李森,王峰,刘帅,等. 综采工作面巡检机器人关键技术研究[J]. 煤炭科学技术,2020,48(7):218-225. doi: 10.13199/j.cnki.cst.2020.07.022LI Sen,WANG Feng,LIU Shuai,et al. Study on key technology of patrol robots for fully-mechanized mining face[J]. Coal Science and Technology,2020,48(7):218-225. doi: 10.13199/j.cnki.cst.2020.07.022 [2] 王国法,范京道,徐亚军,等. 煤炭智能化开采关键技术创新进展与展望[J]. 工矿自动化,2018,44(2):5-12. doi: 10.13272/j.issn.1671-251x.17307WANG Guofa,FAN Jingdao,XU Yajun,et al. Innovation progress and prospect on key technologies of intelligent coal mining[J]. Industry and Mine Automation,2018,44(2):5-12. doi: 10.13272/j.issn.1671-251x.17307 [3] 李首滨,李森,张守祥,等. 综采工作面智能感知与智能控制关键技术与应用[J]. 煤炭科学技术,2021,49(4):28-39. doi: 10.13199/j.cnki.cst.2021.04.004LI Shoubin,LI Sen,ZHANG Shouxiang,et al. Key technology and application of intelligent perception and intelligent control in fully mechanized mining face[J]. Coal Science and Technology,2021,49(4):28-39. doi: 10.13199/j.cnki.cst.2021.04.004 [4] 黄曾华,王峰,张守祥. 智能化采煤系统架构及关键技术研究[J]. 煤炭学报,2020,45(6):1959-1972. doi: 10.13225/j.cnki.jccs.zn20.0348HUANG Zenghua,WANG Feng,ZHANG Shouxiang. Research on the architecture and key technologies of intelligent coal mining system[J]. Journal of China Coal Society,2020,45(6):1959-1972. doi: 10.13225/j.cnki.jccs.zn20.0348 [5] 王海军,刘再斌,雷晓荣,等. 煤矿巷道三维激光扫描关键技术及工程实践[J]. 煤田地质与勘探,2022,50(1):109-117. doi: 10.12363/issn.1001-1986.21.10.0589WANG Haijun,LIU Zaibin,LEI Xiaorong,et al. Key technologies and engineering practice of 3D laser scanning in coal mine roadways[J]. Coal Geology & Exploration,2022,50(1):109-117. doi: 10.12363/issn.1001-1986.21.10.0589 [6] 李首滨. 煤炭智能化无人开采的现状与展望[J]. 中国煤炭,2019,45(4):5-12. doi: 10.3969/j.issn.1006-530X.2019.04.001LI Shoubin. Present situation and prospect on intelligent unmanned mining at work face[J]. China Coal,2019,45(4):5-12. doi: 10.3969/j.issn.1006-530X.2019.04.001 [7] CADENA C,CARLONE L,CARRILLO H,et al. Past,present,and future of simultaneous localization and mapping:toward the robust-perception age[J]. IEEE Transactions on Robotics,2016,32(6):1309-1332. doi: 10.1109/TRO.2016.2624754 [8] BOSSE M,ZLOT R,FLICK P. Zebedee:design of a spring-mounted 3-D range sensor with application to mobile mapping[J]. IEEE Transactions on Robotics,2012,28(5):1104-1119. doi: 10.1109/TRO.2012.2200990 [9] BOSSE M, ZLOT R. Continuous 3D scan-matching with a spinning 2D laser[C]. IEEE International Conference on Robotics and Automation, Kobe, 2009: 4312-4319. [10] PALIERI M,MORRELL B,THAKUR A,et al. LOCUS:a multi-sensor lidar-centric solution for high-precision odometry and 3D mapping in real-time[J]. IEEE Robotics and Automation Letters,2021,6(2):421-428. doi: 10.1109/LRA.2020.3044864 [11] KAESS M,RANGANATHAN A,DELLAERT F. iSAM:incremental smoothing and mapping[J]. IEEE Transactions on Robotics,2008,24(6):1365-1378. doi: 10.1109/TRO.2008.2006706 [12] HACKEL T,WEGNER J D,SCHINDLER K. Fast semantic segmentation of 3d point clouds with strongly varying density[J]. ISPRS Annals of the Photogrammetry,Remote Sensing and Spatial Information Sciences,2016,3:177-184. [13] CAI Zhipeng,CHIN T-J,BUSTOS A P,et al. Practical optimal registration of terrestrial LiDAR scan pairs[J]. ISPRS Journal of Photogrammetry and Remote Sensing,2019,147:118-131. doi: 10.1016/j.isprsjprs.2018.11.016 [14] SEGAL A V, HAEHNEL D, THRUN S. Generalized-ICP[EB/OL]. [2022-05-10]. https://www.robots.ox.ac.uk/~avsegal/resources/papers/Generalized_ICP.pdf. [15] RAMEZANI M, KHOSOUSSI K, CATT G, et al. Wildcat: online continuous-time 3D lidar-inertial SLAM[EB/OL]. [2022-05-10]. https://arxiv.org/abs/2205.12595. [16] GIAMMARINO L D, ALOISE I, STACHNISS C, et al. Visual place recognition using LiDAR intensity information[EB/OL]. [2022-05-10]. https://arxiv.org/abs/2103.09605. [17] MORDOHAI P, MEDIONI G. Tensor voting: a perceptual organization approach to computer vision and machine learning[M]. Cham: Springer, 2006. [18] PAN Yue, XIAO Pengchuan, HE Yujie, et al. MULLS: versatile LiDAR SLAM via multi-metric linear least square[C]. IEEE International Conference on Robotics and Automation, Xi'an, 2021. [19] KANATANI K. 3D rotations: parameter computation and lie algebra-based optimization[M]. Boca Raton: CRC Press, 2020. [20] HUBER P J, RONCHETTI E M. Robust statistics[M]. 2nd Edition. New York: Wiley, 2009. [21] GLADUNOVA O P,RODIONOV E D,SLAVSKII V V. Harmonic tensors on three-dimensional Lie groups with left-invariant Lorentz metric[J]. Doklady Mathematics,2009,80:755-758. doi: 10.1134/S1064562409050329 [22] OHTSUKA T,FUJII H A. Real-time optimization algorithm for nonlinear receding-horizon control[J]. Automatica,1997,33(6):1147-1154. doi: 10.1016/S0005-1098(97)00005-8 [23] KHOSOUSSI K, SUKHATME G S, HUANG S, et al. Designing sparse reliable pose-graph SLAM: a graph-theoretic approach[M]//GOLDBERG K, ABBEEL P, BEKRIS K, et al. Algorithmic foundations of robotics XII. Cham: Springer, 2020: 17-32. -

下载:

下载: