Research on sorting reliability of cable-driven gangue sorting robot system based on fault tree

-

摘要: 拣矸机器人的分拣可靠性与煤的品质及分拣效率息息相关,对拣矸机器人系统分拣可靠性进行研究十分必要。现有机器人系统可靠性研究主要是针对其结构可靠性进行研究,而没有对其工作任务可靠性即分拣可靠性进行研究。针对该问题,以柔索驱动拣矸机器人系统为研究对象,采用故障树分析法对其分拣可靠性进行研究。首先,从拣矸机器人系统的结构出发,分析了拣矸机器人系统分拣故障的原因,采用演绎法构建拣矸机器人系统的分拣故障树;然后,将故障树底事件发生概率考虑为区间变量,根据区间性质、运算法则和顶事件的概率表达式得到分拣故障树顶事件概率区间参数,结合设计要求计算出反映拣矸机器人系统分拣可靠性的非概率可靠性指标;最后,基于非概率可靠性指标公式及模糊重要度定义,提出了一种区间重要度指标,对分拣故障树底事件的区间重要度进行求解并排序,结果表明分拣可靠性满足拣矸机器人可靠分拣要求,煤矸石流瞬时含矸率增大和工业相机故障是影响其分拣可靠性的重要因素。根据非概率可靠性指标计算结果和区间重要度排序找出了拣矸机器人系统的薄弱环节,并针对薄弱环节提出了3个改进措施:在分拣前对煤矸石流振荡混合;根据识别的矸石信息,智能控制带式输送机带速;在拣矸机器人系统中增加备用工业相机。Abstract: The sorting reliability of the gangue sorting robot is closely related to coal quality and sorting efficiency. It is necessary to study the sorting reliability of the sorting robot system. The existing reliability research of robot system mainly focuses on the structural reliability. There is no research on the task reliability of robot system, namely sorting reliability. In order to solve this problem, taking the cable-driven gangue sorting robot system as the research object, the sorting reliability is studied by fault tree analysis. Firstly, based on the structure of the gangue sorting robot system, the reasons for the sorting failure of the gangue sorting robot system are analyzed. The deductive method is used to construct the sorting fault tree of the gangue sorting robot system. Secondly, the occurrence probability of the bottom event of the fault tree is considered as an interval variable. The probability interval parameter of the top event of the sorting fault tree is obtained according to the interval property, the algorithm and the probability expression of the top event. According to the design requirements, the non-probabilistic reliability index which reflects the sorting reliability of the gangue sorting robot system is calculated. Finally, based on the formula of the non-probabilistic reliability index and the definition of fuzzy importance, an interval importance index is proposed. The interval importance of the events at the bottom of the sorting fault tree is solved and ranked. The results show that the sorting reliability can meet the requirements of sorting reliability of the gangue sorting robot. The increase of instantaneous gangue content in coal gangue flow and the failure of the industrial camera are important factors affecting the sorting reliability. According to the calculation result of the non-probability reliability index and the ranking of interval importance, the weak link of the gangue sorting robot system is found. Three improvement measures are proposed for the weak link. It is suggested to shake and mix the coal gangue flow before sorting. According to the identified gangue information, it is suggested to intelligently control the belt speed of the belt conveyor. It is suggested to add spare industrial camera in the gangue sorting robot system.

-

0. 引言

矸石是煤炭开采的伴生废品,直接使用未经处理的原煤会造成资源浪费与环境污染,因此将煤矸分离是煤矿生产过程中的必要工序。而现有的人工分拣工作环境差、劳动强度大,重介洗选消耗介质、生产成本高,浮选污染矿山环境,跳汰分选指标不稳定,已无法适应我国煤炭行业高质量发展要求。采用拣矸机器人进行矸石分拣,可以有效解决传统分选方式存在的问题。目前,国内外学者在拣矸机器人的煤矸识别[1-4]、拣矸路径轨迹规划[5-6]、等效位置工作空间[7]、柔性分拣[8-9]和多机协作分拣[10-12]等方面做了大量研究,但针对拣矸机器人的分拣可靠性研究相对较少。而拣矸机器人的分拣可靠性与煤的品质及分拣效率息息相关,对拣矸机器人系统分拣可靠性进行研究十分必要。

故障树分析法是一种由结果推断原因的图形演绎分析方法,因其简单、直观、有效等优点被广泛应用于机器人可靠性研究。Jiang Guangjun等[13]采用模糊故障树对竞技机器人系统的可靠性进行了分析,为其故障诊断提供理论依据。陈霞[14]采用模糊故障树对蠕动式缆索机器人的可靠性进行了研究,为其可靠性设计提供了理论依据。韩雪等[15]将失效模式与影响分析法和模糊故障树结合,对可缠绕式混合驱动柔索并联机器人可靠性进行了分析。T.A.Ferguson等[16]基于故障树分析对核电站巡检机器人可靠性进行了研究,确定了辐射损害敏感部件故障的故障路径。H.Fazlollahtabar等[17]将故障树分析、可靠性框图和风险决策树结合,对工业机器人可靠性进行了评估。M.Balasundaram等[18]利用改进故障树对机器人系统中出现的故障进行识别,分析了故障概率及故障传播方式。由以上研究可知,故障树分析法既可以对机器人的可靠性进行评估,又可以通过找出机器人的薄弱环节,以提高机器人系统的可靠性,是机器人系统可靠性研究的一种有效方法。但上述研究主要是针对机器人系统结构可靠性进行研究,而没有对机器人工作任务可靠性,即分拣可靠性进行研究。为此,本文以柔索驱动拣矸机器人系统(以下简称拣矸机器人系统)为研究对象,针对其不可靠分拣而降低煤质的问题,采用故障树分析法对拣矸机器人系统分拣可靠性进行研究。通过对造成拣矸机器人系统分拣故障的各种因素进行分析,构建分拣故障树,从而判定拣矸机器人系统是否分拣可靠及寻找出系统的薄弱环节,并采取相应的改进措施,以提高拣矸机器人系统的分拣可靠性。

1. 拣矸机器人系统

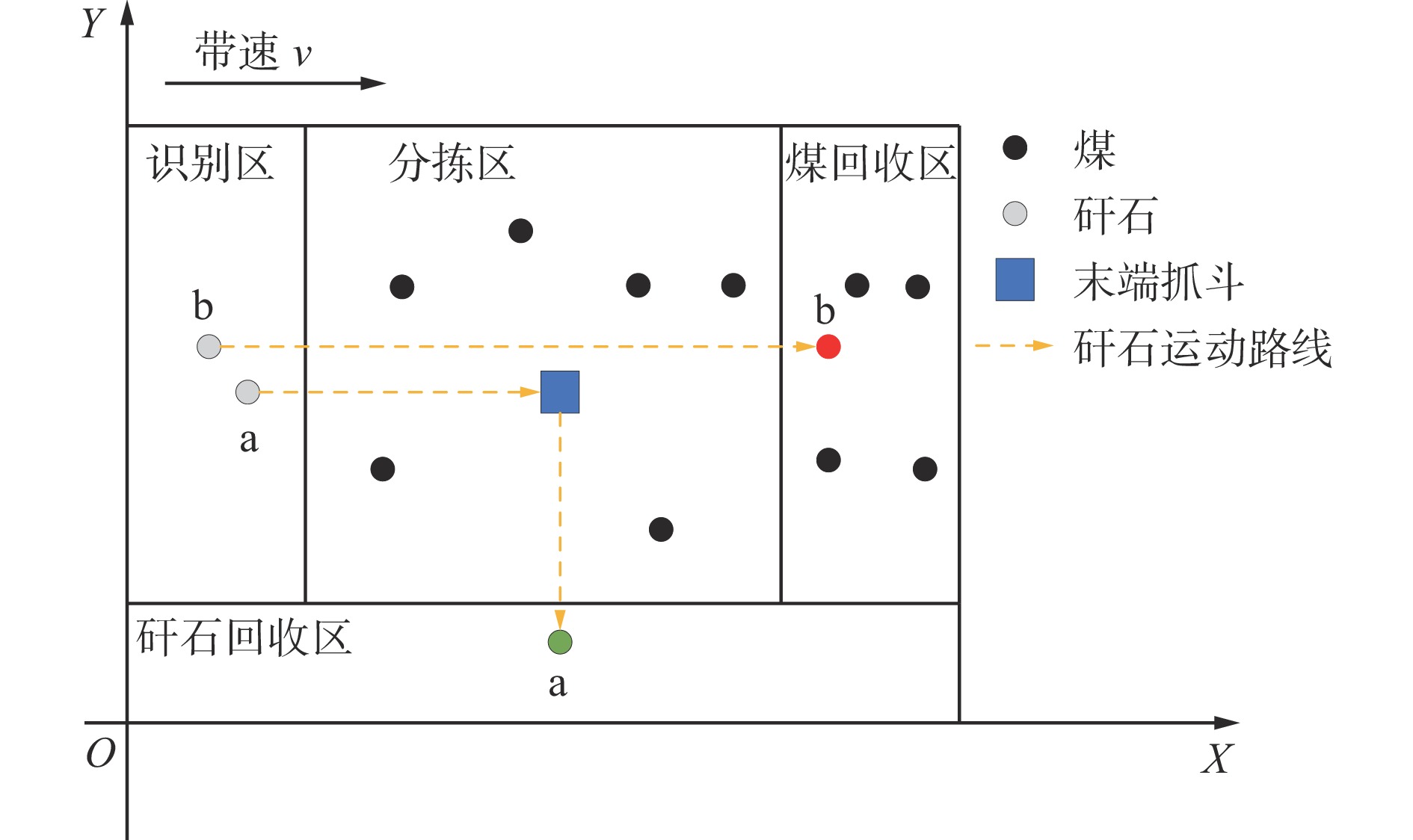

拣矸机器人系统通过4根柔索驱动末端抓斗抓取矸石,完成分拣任务,其结构如图1所示,主要由机械子系统、动力子系统、控制子系统和工业相机构成。机械子系统包括柔索、索架、卷筒、定滑轮和末端抓斗。动力子系统包括伺服电动机、驱动器、编码器、继电器、变压器、熔断器和开关。控制子系统包括工控机和控制程序。在拣矸机器人系统工作时,带式输送机将煤矸石流送至拣矸机器人的识别区,拣矸机器人前端的工业相机获取煤矸石信息,控制子系统中的控制程序将煤矸石信息、带式输送机带速和末端抓斗位置信息处理为控制信号,控制信号经通信线路传递至工控机,工控机将控制信号传输给编码器,编码器控制伺服电动机转动并带动卷筒转动,缠绕在卷筒上的柔索驱动末端抓斗运动到目标矸石位置,进而完成矸石分拣。

2. 分拣故障因素分析与故障树构建

2.1 拣矸机器人系统分拣故障分析

定义拣矸机器人系统分拣出矸石为系统分拣可靠,反之为系统分拣故障。通过对系统分拣故障进行研究可以降低分拣故障发生的概率,进一步提高系统的分拣可靠性。拣矸机器人系统分拣故障包括拣矸机器人系统故障和系统漏拣。

2.1.1 拣矸机器人系统故障

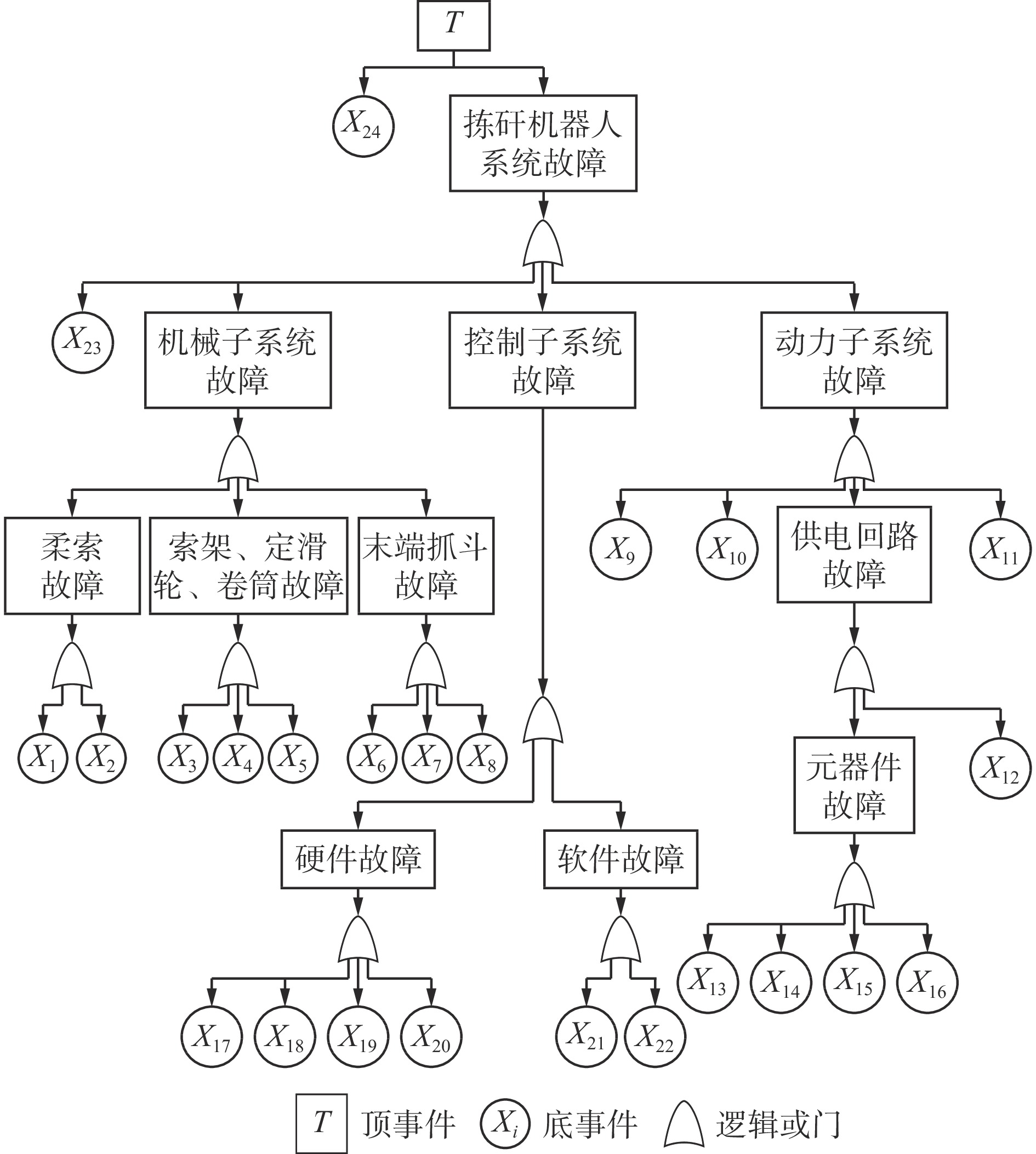

从拣矸机器人系统结构出发,分析拣矸机器人系统故障,将拣矸机器人系统故障分为工业相机故障、机械子系统故障、动力子系统故障和控制子系统故障。机械子系统故障表现在机械结构上,即零件的损坏和零件之间的相互关系破坏。在工作时,柔索收放与定滑轮和卷筒摩擦,长期积累将导致柔索断裂、变形、卷筒磨损破坏和定滑轮磨损破坏等故障。在抓取冲击力和矸石的重力作用下,会引起索架断裂故障。末端抓斗抓取矸石进行上升运动时,末端抓斗的松动会造成矸石掉落,导致末端抓斗抓取掉落故障。在工作过程中,末端抓斗、柔索和卷筒等的连接处出现松动,会导致抓取不到矸石,即末端抓斗空抓故障。动力子系统故障包括驱动器故障、伺服电动机故障、变压器故障和供电回路故障。供电回路故障可分为元器件故障和线路故障。元器件故障包含继电器故障、熔断器故障、开关故障、编码器通信故障。控制子系统故障分为硬件故障和软件故障。软件故障是指控制程序上的加载故障,拣矸机器人在工作时可能出现控制程序无法加载故障和控制程序跑飞故障。硬件故障是指控制元器件故障,有传感器故障、控制卡板故障和工控机故障等。

2.1.2 拣矸机器人系统漏拣

开采的煤炭中矸石分布不均,即带式输送机上的煤矸石流瞬时含矸率动态变化。当瞬时含矸率增大时,矸石之间距离较短。拣矸机器人分拣过程如图2所示,距离较短的a,b两块矸石由识别区进入分拣区,分拣区的末端抓斗首先对前方的a矸石进行分拣,a矸石沿运动路线进入矸石回收区,分拣成功;然后对b矸石进行分拣,因a,b距离较短,在末端抓斗分拣a矸石时,b矸石沿运动路线进入煤回收区,末端抓斗不能进入煤回收区工作,造成b矸石漏拣。

2.2 拣矸机器人系统分拣故障树构建

采用演绎法构建拣矸机器人系统分拣故障树,如图3所示。故障代码对应的事件内容见表1。

表 1 拣矸机器人系统分拣故障树底事件Table 1. Bottom event of sorting fault tree of gangue sorting robot system事件代号 事件内容 事件代号 事件内容 X1 柔索断裂 X13 继电器故障 X2 柔索变形 X14 熔断器故障 X3 索架破坏 X15 开关故障 X4 定滑轮破坏 X16 编码器通信故障 X5 卷筒破坏 X17 传感器故障 X6 末端抓斗定位不准 X18 控制卡板故障 X7 末端抓斗抓取掉落 X19 工控机故障 X8 末端抓斗空抓 X20 集成电路故障 X9 伺服电动机故障 X21 控制程序无法加载 X10 驱动器故障 X22 控制程序跑飞 X11 变压器故障 X23 瞬时含矸率增大 X12 线路故障 X24 工业相机故障 3. 拣矸机器人系统分拣故障树分析

3.1 系统分拣非概率可靠性指标计算

由图3可知,拣矸机器人系统分拣故障树全部由或门构成,并且分拣故障树底事件相互独立,可得顶事件的概率表达式为

$$\begin{split} P = 1 - \prod\limits_{i = 1}^{24} {\left( {1 - {q_i}} \right)} \end{split} $$ (1) 式中

$ P,{q}_{i} $ 分别为分拣故障树顶事件和第$i$ (i=1,2,$\cdots,$ 24)个底事件的发生概率。在传统故障树分析中,要求事件发生的概率精确已知。然而在实际中,由于拣矸机器人的工作环境变化和数据缺乏,无法得到事件精确的发生概率,在此将式(1)中分拣故障树底事件发生概率考虑为区间变量,即

${q_i} \in \left[ {q_i^{\rm{L}},q_i^{\rm{U}}} \right]$ ,对现有数据进行统计分析,给出其下界$q_i^{\rm{L}}$ 和上界$q_i^{\rm{U}}$ ,见表2。表 2 底事件发生概率区间变量的上界和下界Table 2. Upper and lower bounds of the bottom event probability interval底事件

发生概率区间变量

下界区间变量

上界底事件

发生概率区间变量

下界区间变量

上界q1 2.0×10−5 4.0×10−5 q13 5.8×10−4 7.8×10−4 q2 1.6×10−4 2.4×10−4 q14 5.8×10−4 8.2×10−4 q3 1.8×10−4 2.4×10−4 q15 3.0×10−5 5.0×10−5 q4 2.5×10−4 3.5×10−4 q16 5.4×10−4 7.8×10−4 q5 1.3×10−4 1.7×10−4 q17 2.6×10−4 3.8×10−4 q6 5.0×10−4 7.2×10−4 q18 8.0×10−5 1.6×10−4 q7 1.5×10−4 1.9×10−4 q19 3.5×10−4 5.5×10−4 q8 1.0×10−5 3.0×10−5 q20 1.2×10−3 1.6×10−3 q9 5.0×10−4 7.0×10−4 q21 6.0×10−4 1.8×10−3 q10 5.9×10−4 8.1×10−4 q22 2.5×10−4 4.5×10−4 q11 4.0×10−4 6.0×10−4 q23 1.4×10−3 2.6×10−3 q12 1.0×10−5 3.0×10−5 q24 4.2×10−3 4.8×10−3 表2对于2个区间数

$A=[A^{{\rm{L}}}, A^{{\rm{U}}}]$ 和$B=[B^{{\rm{L}}}, B^{{\rm{U}}}]$ ,且区间上下界均为非负数时,其区间减法和乘法运算为$$\left\{ \begin{array}{l} \begin{array}{l}A-B=[{A}^{{\rm{L}}}-{B}^{{\rm{U}}}\text{,}{A}^{{\rm{U}}}-{B}^{{\rm{L}}}]\\ A\times B=[{A}^{{\rm{L}}}\times {B}^{{\rm{L}}}\text{,}{A}^{{\rm{U}}}\times {B}^{{\rm{U}}}]\end{array} \end{array} \right. $$ (2) 当分拣故障树底事件发生概率为区间变量时,顶事件发生概率也为区间变量,则顶事件发生概率区间上下界表达式为

$$ \left\{ {\begin{array}{*{20}{c}} {{P^{\rm{L}}} = 1 - \displaystyle \prod\limits_{i = 1}^{24} {\left( {1 - q_i^{\rm{L}}} \right)} } \\ {{P^{\rm{U}}} = 1 -\displaystyle \prod\limits_{i = 1}^{24} {\left( {1 - q_i^{\rm{U}}} \right)} } \end{array}} \right. $$ (3) 式中

$ {P}^{{\rm{L}}},{P}^{{\rm{U}}} $ 分别为分拣故障树顶事件发生概率区间的下界和上界。根据区间的性质,可得

$$ \left\{ {\begin{array}{*{20}{c}} {{P^{\rm{c}}} = \dfrac{{{P^{\rm{U}}} + {P^{\rm{L}}}}}{2} = 1 - \dfrac{{\displaystyle \prod\limits_{i = 1}^{24} {\left( {1 - q_i^{\rm{L}}} \right)} + \displaystyle \prod\limits_{i = 1}^{24} {\left( {1 - q_i^{\rm{U}}} \right)} }}{2}} \\ {{P^{\rm{r}}} = \dfrac{{{P^{\rm{U}}} - {P^{\rm{L}}}}}{2} = \dfrac{{\displaystyle \prod\limits_{i = 1}^{24} {\left( {1 - q_i^{\rm{L}}} \right)} - \displaystyle \prod\limits_{i = 1}^{24} {\left( {1 - q_i^{\rm{U}}} \right)} }}{2}} \end{array}} \right. $$ (4) 式中

$ {P}^{{\rm{c}}},{P}^{{\rm{r}}} $ 分别为分拣故障树顶事件发生概率区间的中值和离差。将式(4)代入拣矸机器人系统非概率可靠性指标

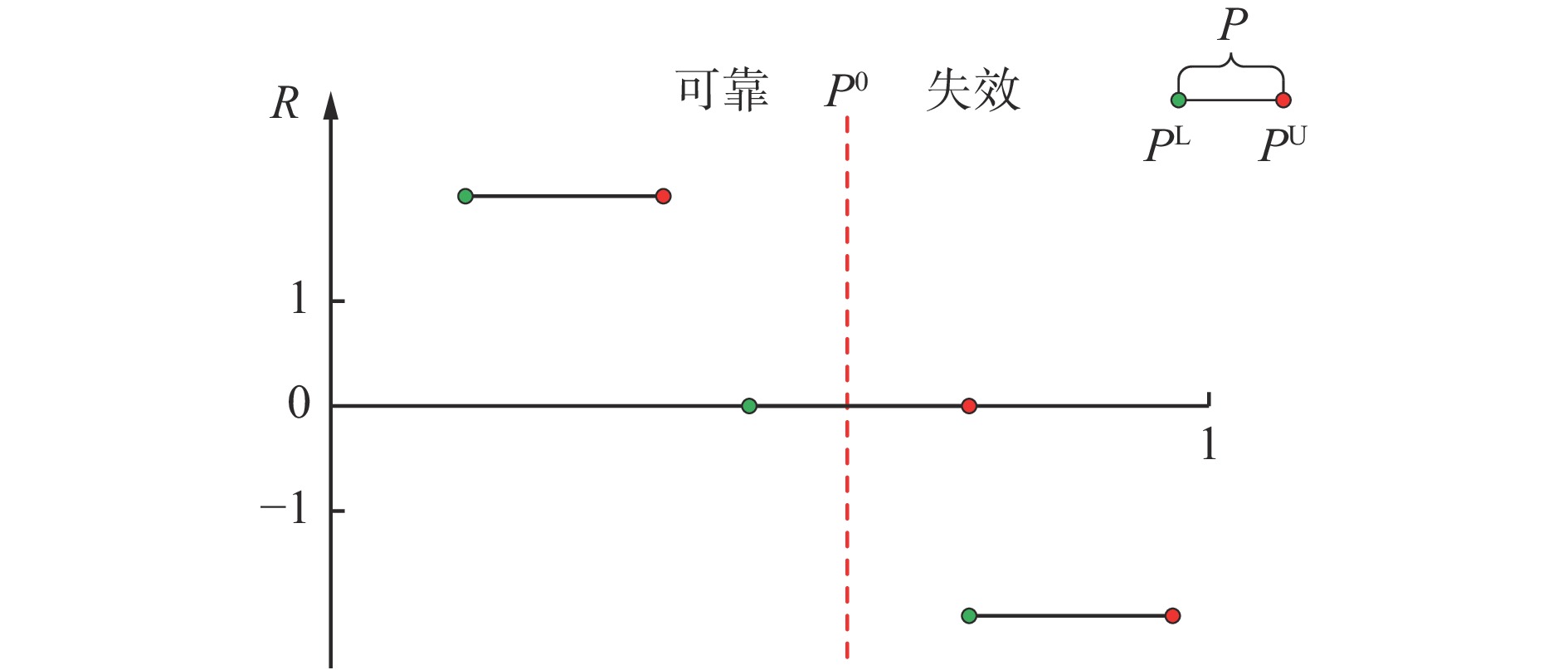

$R$ [19]的表达式,得到非概率可靠性指标R与底事件发生概率区间下界$q_i^{\rm{L}}$ 和上界$q_i^{\rm{U}}$ 的函数表达式为$$ R = \frac{{{P^0} - {P^{\rm{c}}}}}{{{P^{\rm{r}}}}} = \frac{{2{P^0} - 2 + \displaystyle \prod\limits_{i = 1}^{24} {\left( {1 - q_i^{\rm{L}}} \right)} + \displaystyle \prod\limits_{i = 1}^{24} {\left( {1 - q_i^{\rm{U}}} \right)} }}{{\displaystyle \prod\limits_{i = 1}^{24} {\left( {1 - q_i^{\rm{L}}} \right)} - \displaystyle \prod\limits_{i = 1}^{24} {\left( {1 - q_i^{\rm{U}}} \right)} }} $$ (5) 通过商品煤的含矸率标准设计的拣矸机器人系统分拣率为98%,由分拣率得到拣矸机器人系统分拣可靠性要求

${P^0}$ (阈值)为$2 \times 10^{-2}$ ,即拣矸机器人系统未分拣出矸石的概率不得超过$2 \times 10^{-2}$ 。将${P^0}$ 和表2中的数据代入式(5),得到拣矸机器人系统非概率可靠性指标R。用非概率可靠性指标R判定拣矸机器人系统的可靠性是否满足要求,如图4所示。(1) 当

$ R>1 $ 时,即${P^{\rm{U}}} < {P^0}$ ,拣矸机器人系统分拣故障概率的所有可能取值均小于$ P^{0} $ ,系统可靠。(2) 当

$ -1 \leq R \leq 1 $ 时,即${P^{\rm{L}}} < {P^0} < {P^{\rm{U}}}$ ,拣矸机器人系统分拣故障概率区间部分可靠,部分失效,系统可靠性不确定。(3) 当

$ R<-1 $ 时,即${P^0} < {P^{\rm{L}}}$ ,拣矸机器人系统分拣故障概率的所有可能取值均大于$ P^{0} $ ,系统失效。根据计算得到

$R = 1.9277 > 1$ ,可以判定拣矸机器人系统分拣可靠性满足要求。3.2 底事件区间重要度评判

为进一步提高拣矸机器人系统分拣可靠性,需要找出拣矸机器人系统的薄弱环节,并对薄弱环节进行优化处理。

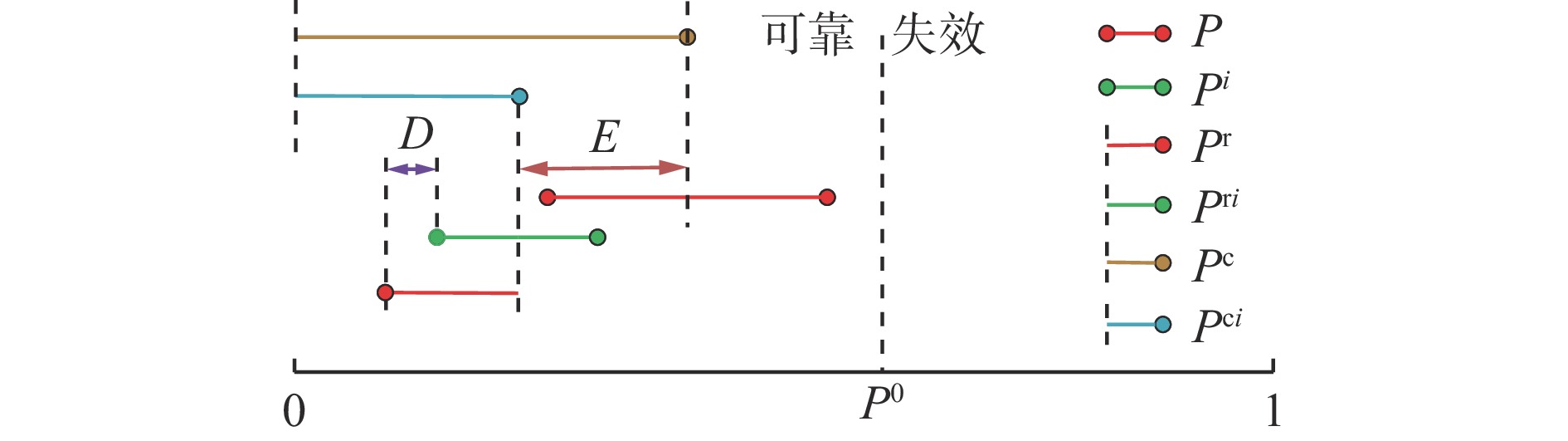

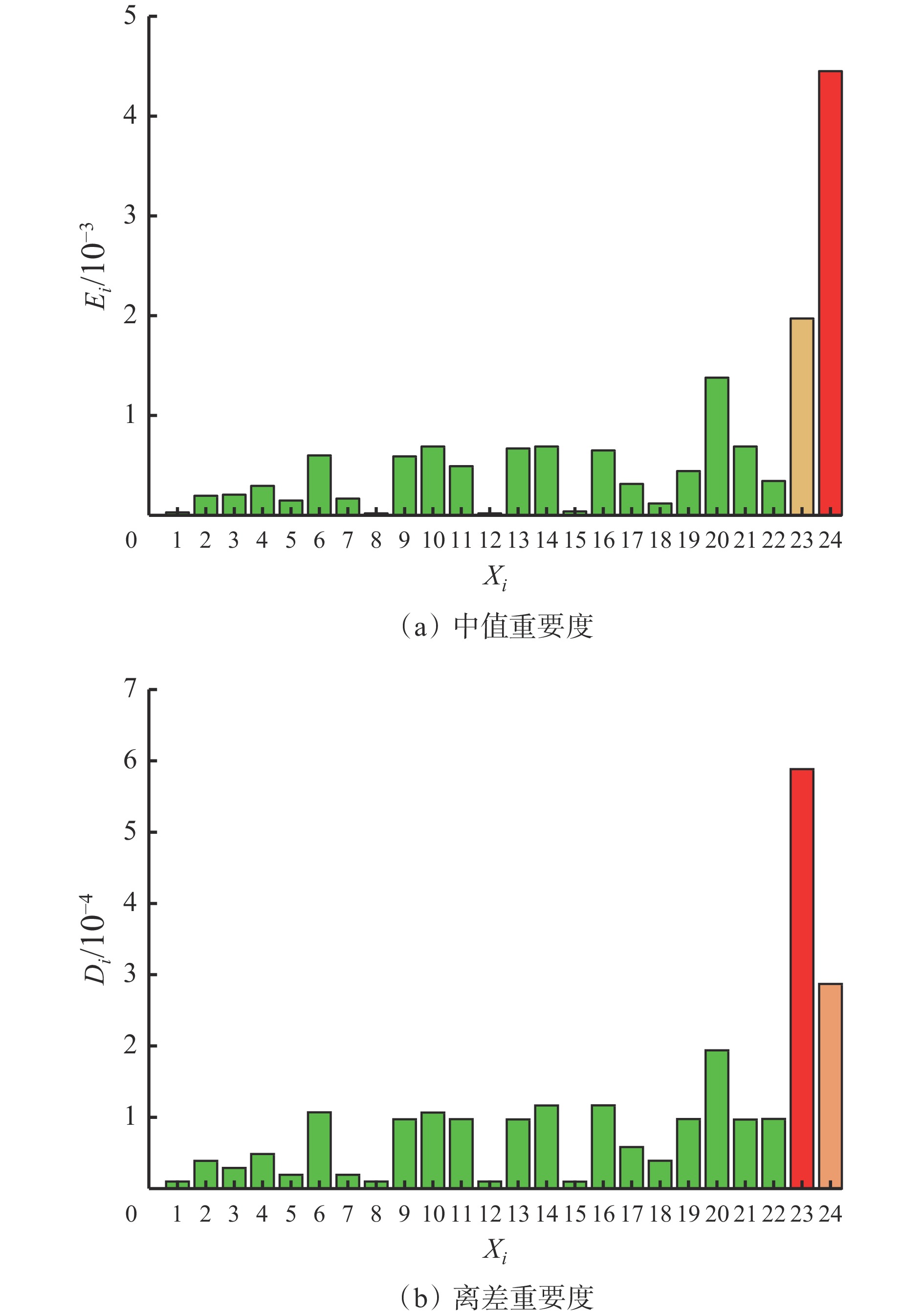

在故障树分析中,用底事件重要度来衡量底事件对顶事件发生的贡献度,其值越大,说明该底事件所处的环节越薄弱,其位置越重要。传统的重要度如结构重要度[20]、概率重要度[21]和关键性重要度[22],未考虑底事件的不确定性,具有局限性。为此,本文基于非概率可靠性指标,借鉴文献[23]提出的模糊重要度概念,提出了一种区间重要度概念,以衡量底事件对顶事件发生的贡献度。中值重要度与离差重要度如图5所示。

$P^{{\rm{r}} i}$ 与$P^{{\rm{c}} i}$ 分别为第$i$ 个底事件不发生情况下顶事件概率区间的中值和离差,E和D分别为$ P^{{\rm{c}}} $ ,$ P^{{\rm{c}} i } $ ,$ P^{{\rm{r}}} $ ,$ P^{{\rm{r}} i } $ 差值的绝对值,$ E $ 与$ D $ 值越大,表明该底事件的概率区间对顶事件的概率区间中值和离差影响越大。Ei,Di具体表达式为

$$\left\{ \begin{array}{l} \begin{gathered} {E_i} = \left| {{P^{\rm{c}}} - {P^{{\rm{c}}i}}} \right| = \frac{{\left| {\displaystyle \prod\limits_{j = 1,i \ne j}^{24} {\left( {1 - q_j^{\rm{L}}} \right)q_i^{\rm{L}}} + \displaystyle \prod\limits_{j = 1,i \ne j}^{24} {\left( {1 - q_j^{\rm{U}}} \right)q_i^{\rm{U}}} } \right|}}{2} \\ {D_i} = \left| {{P^{\rm{r}}} - {P^{{\rm{r}}i}}} \right| = \frac{{\left| {\displaystyle \prod\limits_{j = 1,i \ne j}^{24} {\left( {1 - q_j^{\rm{U}}} \right)q_i^{\rm{U}}} - \displaystyle \prod\limits_{j = 1,i \ne j}^{24} {\left( {1 - q_j^{\rm{L}}} \right)q_i^{\rm{L}}} } \right|}}{2} \\ \end{gathered} \end{array} \right.$$ (6) 式中:

$ {E}_{i},{D}_{i} $ 分别为第$i$ 个底事件的中值重要度和离差重要度;$ q_j^{\rm{L}} $ 和$ q_j^{\rm{U}} $ 分别为第$j$ 个底事件发生概率区间的下界和上界。将表2中的数据代入式(6),可计算得到底事件的中值重要度和离差重要度,见表3。

表 3 底事件区间重要度计算结果Table 3. Calculation results of the interval importance degree of the bottom event底事件 Ei Di 底事件 Ei Di X1 2.95×10−5 9.77×10−6 X13 6.70×10−4 9.70×10−5 X2 1.97×10−4 3.89×10−5 X14 6.89×10−4 1.16×10−4 X3 2.07×10−4 2.90×10−5 X15 3.94×10−5 9.75×10−6 X4 2.95×10−4 4.85×10−5 X16 6.50×10−4 1.16×10−4 X5 1.48×10−4 1.93×10−5 X17 3.15×10−4 5.83×10−5 X6 6.01×10−4 1.07×10−4 X18 1.18×10−4 3.91×10−5 X7 1.67×10−4 1.93×10−5 X19 4.43×10−4 9.75×10−5 X8 1.97×10−5 9.80×10−6 X20 1.38×10−3 1.94×10−4 X9 5.91×10−4 9.71×10−5 X21 6.90×10−4 9.70×10−5 X10 6.90×10−4 1.07×10−4 X22 3.45×10−4 9.77×10−5 X11 4.92×10−4 9.73×10−5 X23 1.97×10−3 5.88×10−4 X12 1.97×10−5 9.80×10−6 X24 4.45×10−3 2.87×10−4 对表3中的底事件的中值和离差重要度进行排序,结果如下:E24>E23>E20>E21=E10>E14>E13>E16>E6>E9>E11>E19>E22>E17>E4>E3>E2>E7>E5>E18>E15>E1>E8=E12;D23>D24>D20>D16=D14>D6>D10>D22>D19>D11>D9>D13=D21>D17>D4>D18>D2>D3>D5=D7>D8=D12>D1>D15。

为便于直观分析,图6给出了底事件中值重要度与离差重要度对比。

从图6可看出,对拣矸机器人系统分拣故障树顶事件发生概率区间中值贡献最大的底事件是

${X_{24}}$ ,其次是${X_{23}}$ ,剩余底事件贡献较小;而对拣矸机器人系统分拣故障树顶事件发生概率区间离差贡献最大的底事件是${X_{23}}$ ,其次是${X_{24}}$ ,剩余底事件贡献较小。基于上述判断,可采取如下措施提高拣矸机器人系统的分拣可靠性:

(1) 在分拣前对煤矸石流振荡混合,使煤矸石流中的矸石分布均匀,减小其瞬时含矸率的波动。

(2) 根据识别的矸石信息,对带式输送机的带速进行智能控制,当瞬时含矸率大时,降低带速;当瞬时含矸率小时,提高带速。

(3) 在拣矸机器人系统中增加备用工业相机,当工作相机故障时启用备用相机对煤矸石进行识别。

4. 结论

(1) 将故障树分析法应用于拣矸机器人系统的分拣可靠性研究,通过分析拣矸机器人系统分拣故障原因,构建了分拣故障树。

(2) 结合区间理论对分拣故障树进行定量分析,计算出拣矸机器人系统的非概率可靠性指标,计算结果显示拣矸机器人系统满足分拣可靠性要求。

(3) 给出了区间重要度定义及计算公式,得到底事件的中值重要度和离差重要度排序,综合确定煤矸石流瞬时含矸率增大和工业相机故障是影响系统分拣可靠性的关键因素,并针对关键因素提出了振荡混合煤矸石流、智能控制带速和增加备用工业相机3个改进措施。

-

表 1 拣矸机器人系统分拣故障树底事件

Table 1 Bottom event of sorting fault tree of gangue sorting robot system

事件代号 事件内容 事件代号 事件内容 X1 柔索断裂 X13 继电器故障 X2 柔索变形 X14 熔断器故障 X3 索架破坏 X15 开关故障 X4 定滑轮破坏 X16 编码器通信故障 X5 卷筒破坏 X17 传感器故障 X6 末端抓斗定位不准 X18 控制卡板故障 X7 末端抓斗抓取掉落 X19 工控机故障 X8 末端抓斗空抓 X20 集成电路故障 X9 伺服电动机故障 X21 控制程序无法加载 X10 驱动器故障 X22 控制程序跑飞 X11 变压器故障 X23 瞬时含矸率增大 X12 线路故障 X24 工业相机故障 表 2 底事件发生概率区间变量的上界和下界

Table 2 Upper and lower bounds of the bottom event probability interval

底事件

发生概率区间变量

下界区间变量

上界底事件

发生概率区间变量

下界区间变量

上界q1 2.0×10−5 4.0×10−5 q13 5.8×10−4 7.8×10−4 q2 1.6×10−4 2.4×10−4 q14 5.8×10−4 8.2×10−4 q3 1.8×10−4 2.4×10−4 q15 3.0×10−5 5.0×10−5 q4 2.5×10−4 3.5×10−4 q16 5.4×10−4 7.8×10−4 q5 1.3×10−4 1.7×10−4 q17 2.6×10−4 3.8×10−4 q6 5.0×10−4 7.2×10−4 q18 8.0×10−5 1.6×10−4 q7 1.5×10−4 1.9×10−4 q19 3.5×10−4 5.5×10−4 q8 1.0×10−5 3.0×10−5 q20 1.2×10−3 1.6×10−3 q9 5.0×10−4 7.0×10−4 q21 6.0×10−4 1.8×10−3 q10 5.9×10−4 8.1×10−4 q22 2.5×10−4 4.5×10−4 q11 4.0×10−4 6.0×10−4 q23 1.4×10−3 2.6×10−3 q12 1.0×10−5 3.0×10−5 q24 4.2×10−3 4.8×10−3 表 3 底事件区间重要度计算结果

Table 3 Calculation results of the interval importance degree of the bottom event

底事件 Ei Di 底事件 Ei Di X1 2.95×10−5 9.77×10−6 X13 6.70×10−4 9.70×10−5 X2 1.97×10−4 3.89×10−5 X14 6.89×10−4 1.16×10−4 X3 2.07×10−4 2.90×10−5 X15 3.94×10−5 9.75×10−6 X4 2.95×10−4 4.85×10−5 X16 6.50×10−4 1.16×10−4 X5 1.48×10−4 1.93×10−5 X17 3.15×10−4 5.83×10−5 X6 6.01×10−4 1.07×10−4 X18 1.18×10−4 3.91×10−5 X7 1.67×10−4 1.93×10−5 X19 4.43×10−4 9.75×10−5 X8 1.97×10−5 9.80×10−6 X20 1.38×10−3 1.94×10−4 X9 5.91×10−4 9.71×10−5 X21 6.90×10−4 9.70×10−5 X10 6.90×10−4 1.07×10−4 X22 3.45×10−4 9.77×10−5 X11 4.92×10−4 9.73×10−5 X23 1.97×10−3 5.88×10−4 X12 1.97×10−5 9.80×10−6 X24 4.45×10−3 2.87×10−4 -

[1] HOU Wei. Identification of coal and gangue by feed-forward neural network based on data analysis[J]. International Journal of Coal Preparation and Utilization,2019,39(1):33-43. DOI: 10.1080/19392699.2017.1290609

[2] 来文豪,周孟然,胡锋,等. 基于多光谱成像和改进YOLO v4的煤矸石检测[J]. 光学学报,2020,40(24):72-80. LAI Wenhao,ZHOU Mengran,HU Feng,et al. Coal gangue detection based on multi-spectral imaging and improved YOLO v4[J]. Acta Optica Sinica,2020,40(24):72-80.

[3] LI Man,DUAN Yong,HE Xianli,et al. Image positioning and identification method and system for coal and gangue sorting robot[J]. International Journal of Coal Preparation and Utilization,2020,40(4):1759-1777.

[4] SUN Zhiyuan, HUANG Linlin, JIA Ruiqing. Coal and gangue separating robot system based on computer vision[J]. Sensors, 2021, 21(4): 1349. DOI: 10.3390/s21041349.

[5] 夏晶,张昊,周世宁,等. 煤矸分拣机器人动态拣取避障路径规划[J]. 煤炭学报,2021,46(增刊1):570-577. DOI: 10.13225/j.cnki.jccs.2020.1448 XIA Jing,ZHANG Hao,ZHOU Shining,et al. Dynamic picking and obstacle avoidance path planning of coal gangue sorting robot[J]. Journal of China Coal Society,2021,46(S1):570-577. DOI: 10.13225/j.cnki.jccs.2020.1448

[6] 赵明辉. 双臂并联煤矸石分拣机器人及其轨迹规划研究[J]. 工矿自动化,2020,46(9):57-63. DOI: 10.13272/j.issn.1671-251x.2020040059 ZHAO Minghui. Research on dual-arm parallel coal gangue sorting robot and its trajectory planning[J]. Industry and Mine Automation,2020,46(9):57-63. DOI: 10.13272/j.issn.1671-251x.2020040059

[7] LIU Peng, MA Hongwei, ZHANG Xuhui, et al. On the equivalent position workspace for a coal gangue picking robot [J]. Journal of Physics: Conference Series, 2019, 1267(1). DOI: 10.1088/1742-6596/1267/1/012078.

[8] WANG Zixiang,XIE Shuxin,CHEN Guodong,et al. An online flexible sorting model for coal and gangue based on multi-information fusion[J]. IEEE Access,2021,9:90816-90827. DOI: 10.1109/ACCESS.2021.3090780

[9] 刘鹏,马宏伟,乔心州,等. 柔索驱动拣矸机器人最小索拉力等值曲面研究[J]. 西安科技大学学报,2020,40(5):797-804. DOI: 10.13800/j.cnki.xakjdxxb.2020.0507 LIU Peng,MA Hongwei,QIAO Xinzhou,et al. On the contour surfaces of minimum tensions for a cable-driven coal-gangue picking gangue robot[J]. Journal of Xi'an University of Science and Technology,2020,40(5):797-804. DOI: 10.13800/j.cnki.xakjdxxb.2020.0507

[10] 曹现刚,吴旭东,王鹏,等. 面向煤矸分拣机器人的多机械臂协同策略[J]. 煤炭学报,2019,44(增刊2):763-774. DOI: 10.13225/j.cnki.jccs.2019.0734 CAO Xiangang,WU Xudong,WANG Peng,et al. Collaborative strategy of multi-manipulator for coal-gangue sorting robot[J]. Journal of China Coal Society,2019,44(S2):763-774. DOI: 10.13225/j.cnki.jccs.2019.0734

[11] 曹现刚,费佳浩,王鹏,等. 基于多机械臂协同的煤矸分拣方法研究[J]. 煤炭科学技术,2019,47(4):7-12. DOI: 10.13199/j.cnki.cst.2019.04.002 CAO Xiangang,FEI Jiahao,WANG Peng,et al. Study on coal-gangue sorting method based on multi-manipulator collaboration[J]. Coal Science and Technology,2019,47(4):7-12. DOI: 10.13199/j.cnki.cst.2019.04.002

[12] 王鹏,曹现刚,夏晶,等. 基于机器视觉的多机械臂煤矸石分拣机器人系统研究[J]. 工矿自动化,2019,45(9):47-53. DOI: 10.13272/j.issn.1671-251x.17442 WANG Peng,CAO Xiangang,XIA Jing,et al. Research on multi-manipulator coal and gangue sorting robot system based on machine vision[J]. Industry and Mine Automation,2019,45(9):47-53. DOI: 10.13272/j.issn.1671-251x.17442

[13] JIANG Guangjun,GAO Le. Reliability analysis of martial arts arena robot systems based on fuzzy set theory[J]. Journal of Mechanical Science and Technology,2018,32(11):5069-5077. DOI: 10.1007/s12206-018-1003-1

[14] 陈霞. 蠕动式缆索机器人模糊故障树分析与应用[J]. 机械设计,2015,32(8):31-35. DOI: 10.13841/j.cnki.jxsj.2015.08.007 CHEN Xia. Analysis and application of the worming cable robot fuzzy fault tree[J]. Journal of Machine Design,2015,32(8):31-35. DOI: 10.13841/j.cnki.jxsj.2015.08.007

[15] 韩雪,訾斌,孙辉辉. 可缠绕式混合驱动柔索并联机器人可靠性分析[J]. 机械设计与制造,2015(4):155-158,162. DOI: 10.3969/j.issn.1001-3997.2015.04.043 HAN Xue,ZI Bin,SUN Huihui. The reliability analysis of the winding hybrid-driven cable parallel manipulator[J]. Machinery Design & Manufacture,2015(4):155-158,162. DOI: 10.3969/j.issn.1001-3997.2015.04.043

[16] FERSGUSON T A, LU Lixuan. Fault tree analysis for an inspection robot in a nuclear power plant[EB/OL]. [2022-03-11]. https://iopscience.iop.org/article/10.1088/1757-899X/235/1/012003/meta.

[17] FAZLOLLAHTABAR H,NIAKI S. Integration of fault tree analysis,reliability block diagram and hazard decision tree for industrial robot reliability evaluation[J]. Industrial Robot,2017,44(6):754-764. DOI: 10.1108/IR-06-2017-0103

[18] BALASUNDARAM M,MUTHUSWAMY S. Implementation of role assignment and fault tree analysis for multi robot interaction[J]. International Journal of Robotics and Automation,2017,32(3):214-223.

[19] 周长聪, 常琦, 周春苹, 等. 基于非概率模型的飞机襟翼故障树分析[J]. 清华大学学报(自然科学版), 2021, 61(6): 636-642. ZHOU Changcong, CHANG Qi, ZHOU Chunping,et al. Fault tree analysis of an aircraft flap system based on a non-probability model[J]. Journal of Tsinghua University (Science and Technology), 2021, 61(6): 636-642.

[20] 方坤,陶军. 液压ABS系统的故障树分析[J]. 液压与气动,2020,44(2):155-161. FANG Kun,TAO Jun. Fault tree analysis of hydraulic ABS system[J]. Chinese Hydraulics and Pneumatics,2020,44(2):155-161.

[21] 庞楠,贾鹏,王立权,等. 水下连接器结构可靠性分析[J]. 哈尔滨工程大学学报,2021,42(1):68-73. PANG Nan,JIA Peng,WANG Liquan,et al. Reliability analysis of subsea connector structure[J]. Journal of Harbin Engineering University,2021,42(1):68-73.

[22] 罗承昆,陈云翔,何桢,等. 基于故障树分析的航空装备体系结构贡献率评估方法[J]. 国防科技大学学报,2021,43(1):155-162. LUO Chengkun,CHEN Yunxiang,HE Zhen,et al. Evaluation method of aviation equipment's structure contribution rate to system-of-system based on fault tree analysis[J]. Journal of National University of Defense Technology,2021,43(1):155-162.

[23] CHENG S R,LIU B S,HSU B M,et al. Fault-tree analysis for liquefied natural gas terminal emergency shutdown system[J]. Expert Systems with Applications,2009,36(9):11918-11924.

-

期刊类型引用(4)

1. 谢雨,邱伊健. 基于改进贪心算法的工业机器人分拣装配协同控制系统设计. 计算机测量与控制. 2025(03): 105-112+137 .  百度学术

百度学术

2. 张宇轩,马增强,远松灵. 基于动态故障树的交通信号灯监测系统故障分析. 国防交通工程与技术. 2024(04): 27-30+56+61 .  百度学术

百度学术

3. 梁倍源,陈路. 基于OMRON视觉的工业机器人分拣控制系统设计. 计算机测量与控制. 2024(07): 105-111 .  百度学术

百度学术

4. 黄文财,钟远生,朱晓鹏,蒋美玲. 基于组合赋权的配送机器人软件易用性评估. 机电工程技术. 2023(11): 120-122+155 .  百度学术

百度学术

其他类型引用(4)

下载:

下载: