Analysis and optimization method of monitoring capability of coal mine microseismic monitoring network

-

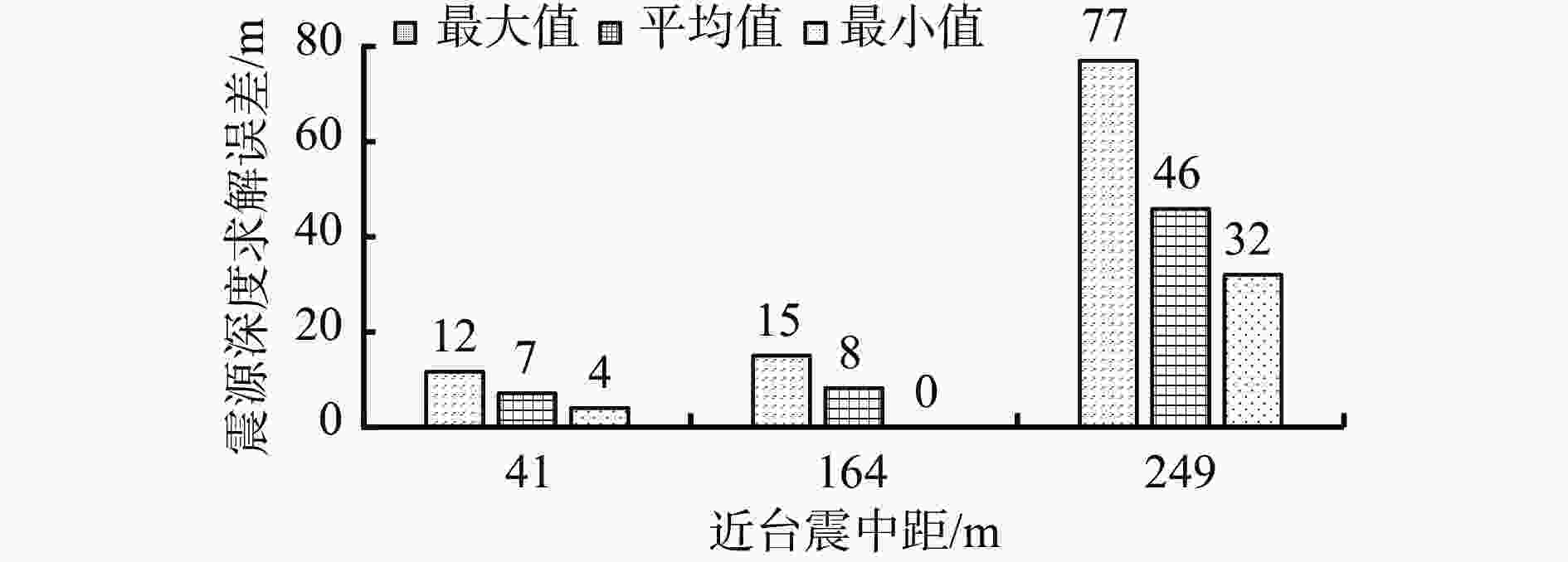

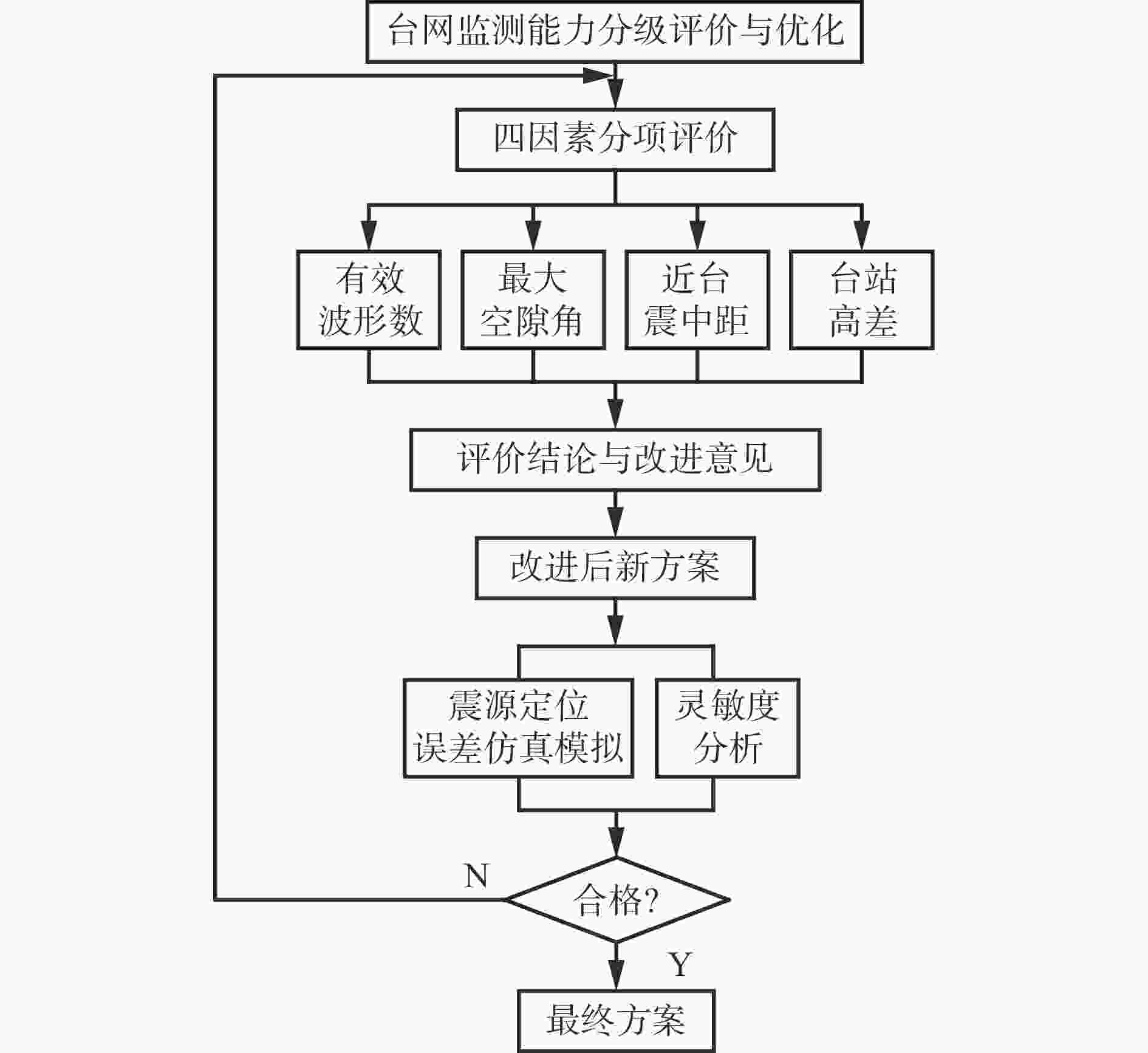

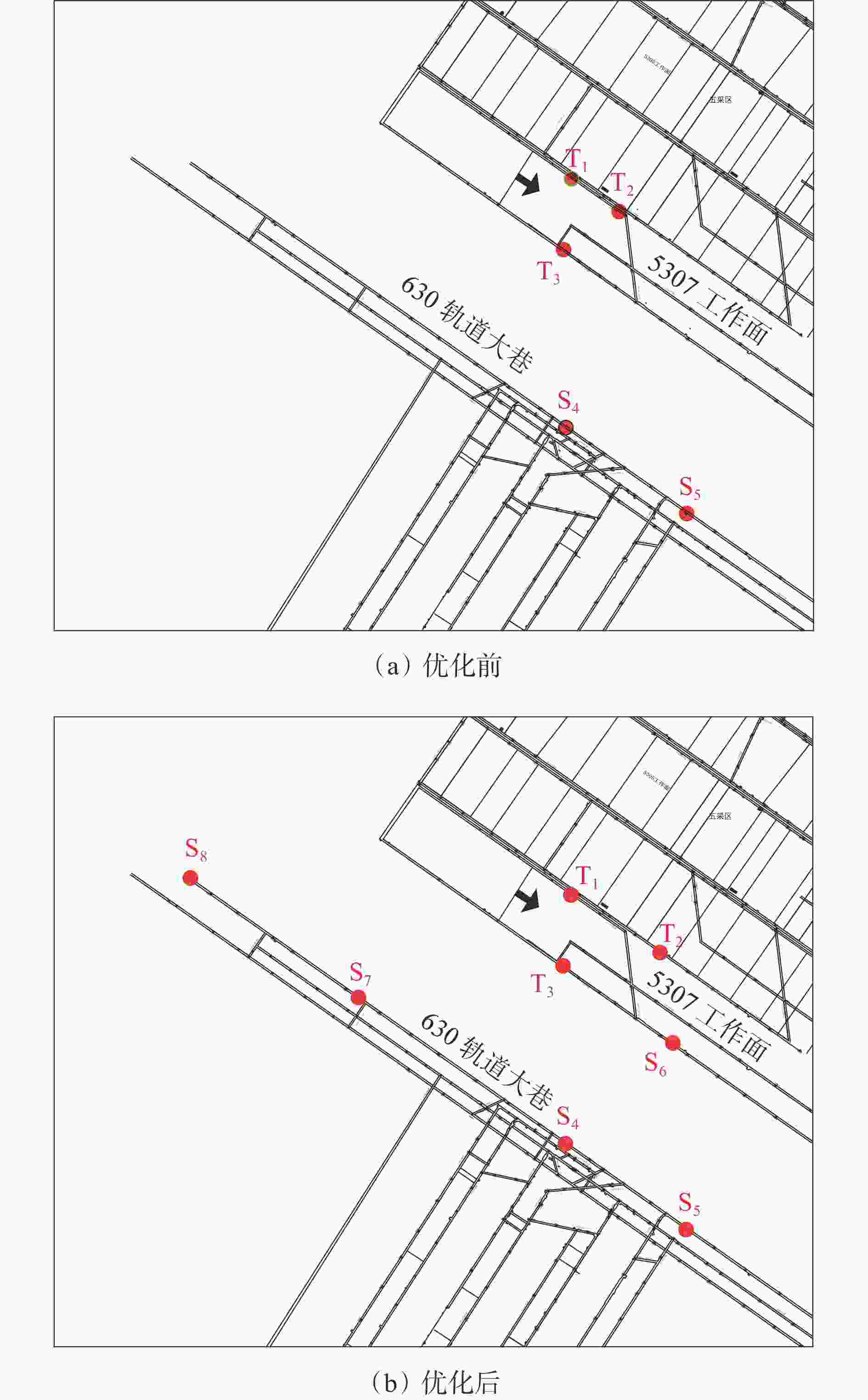

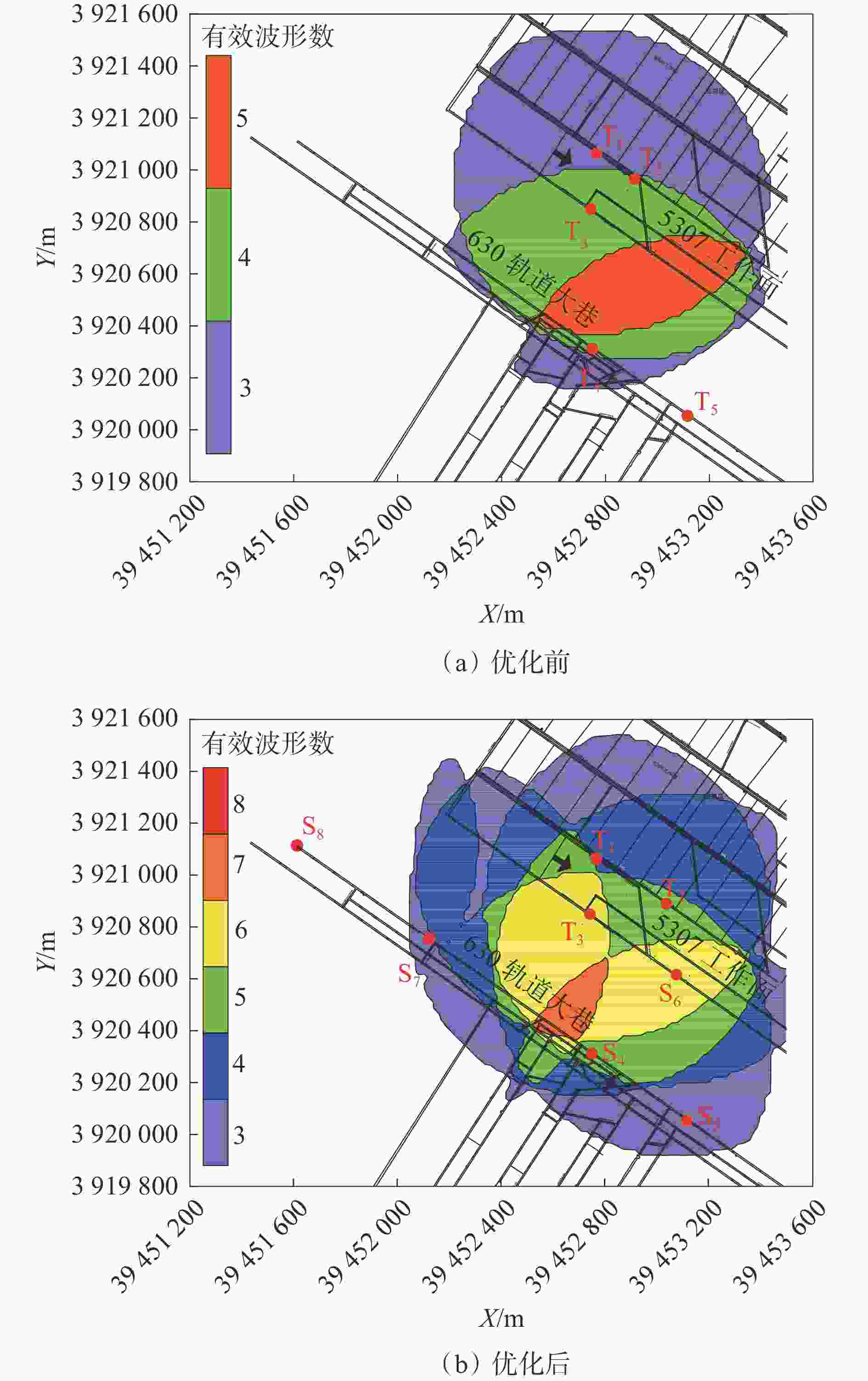

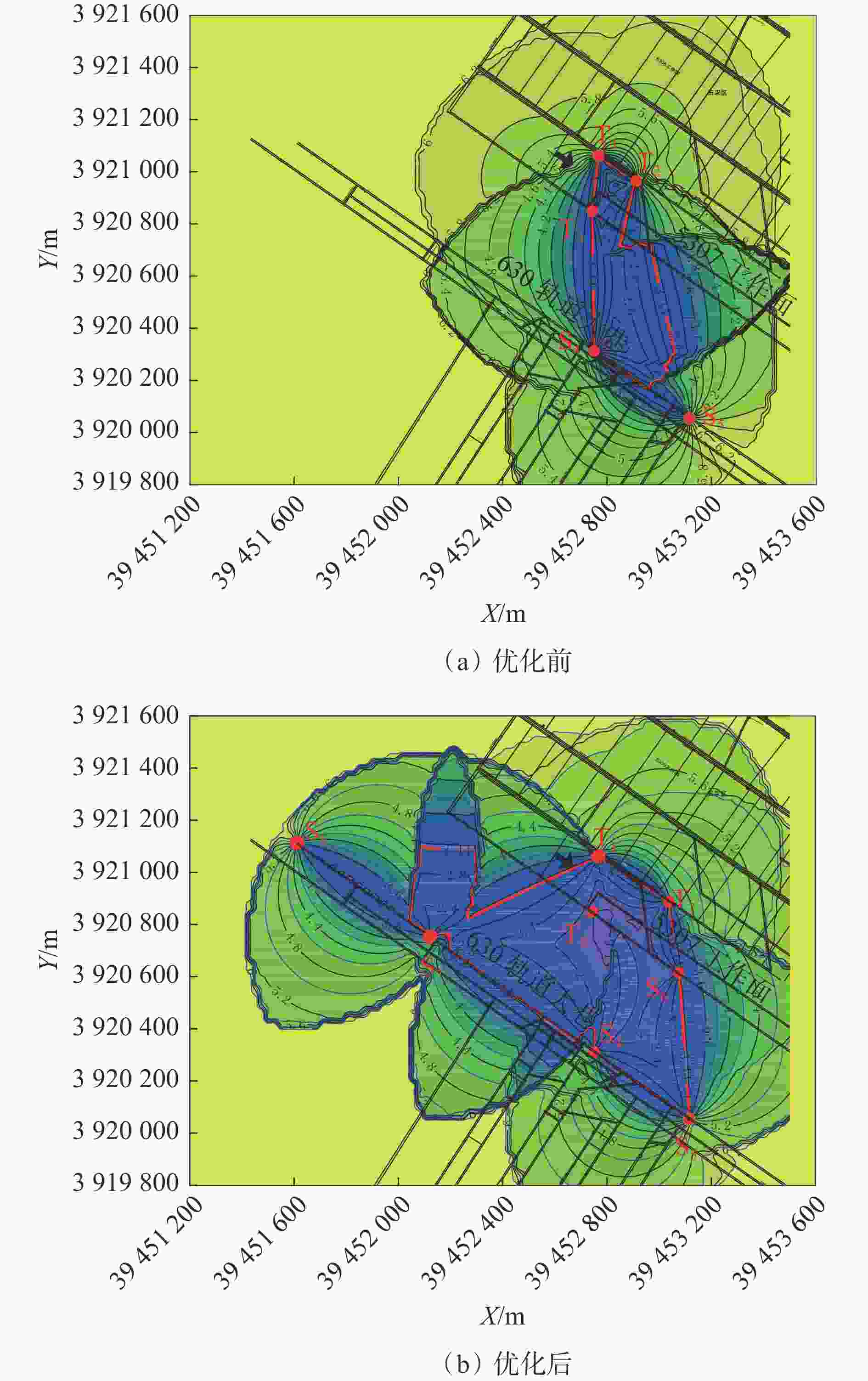

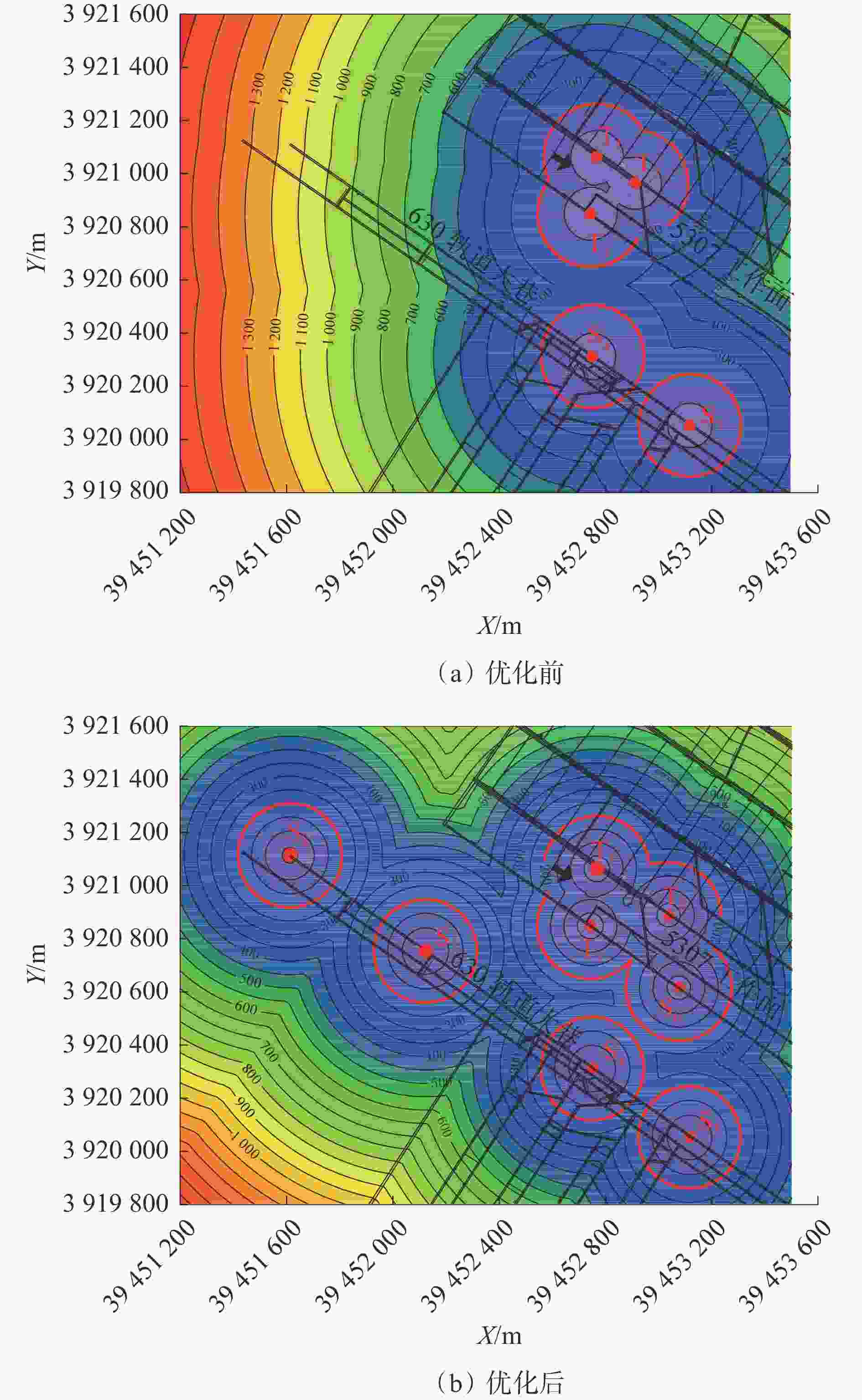

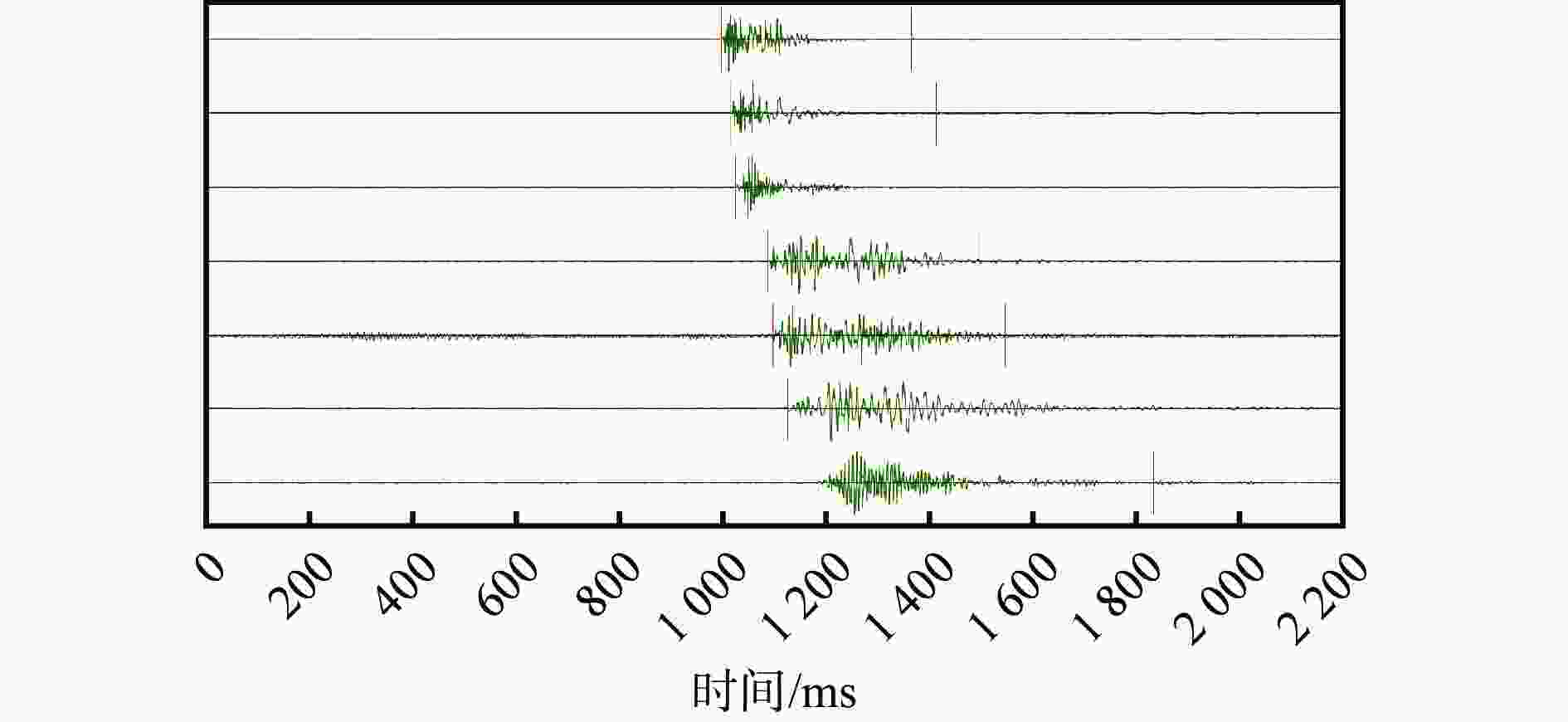

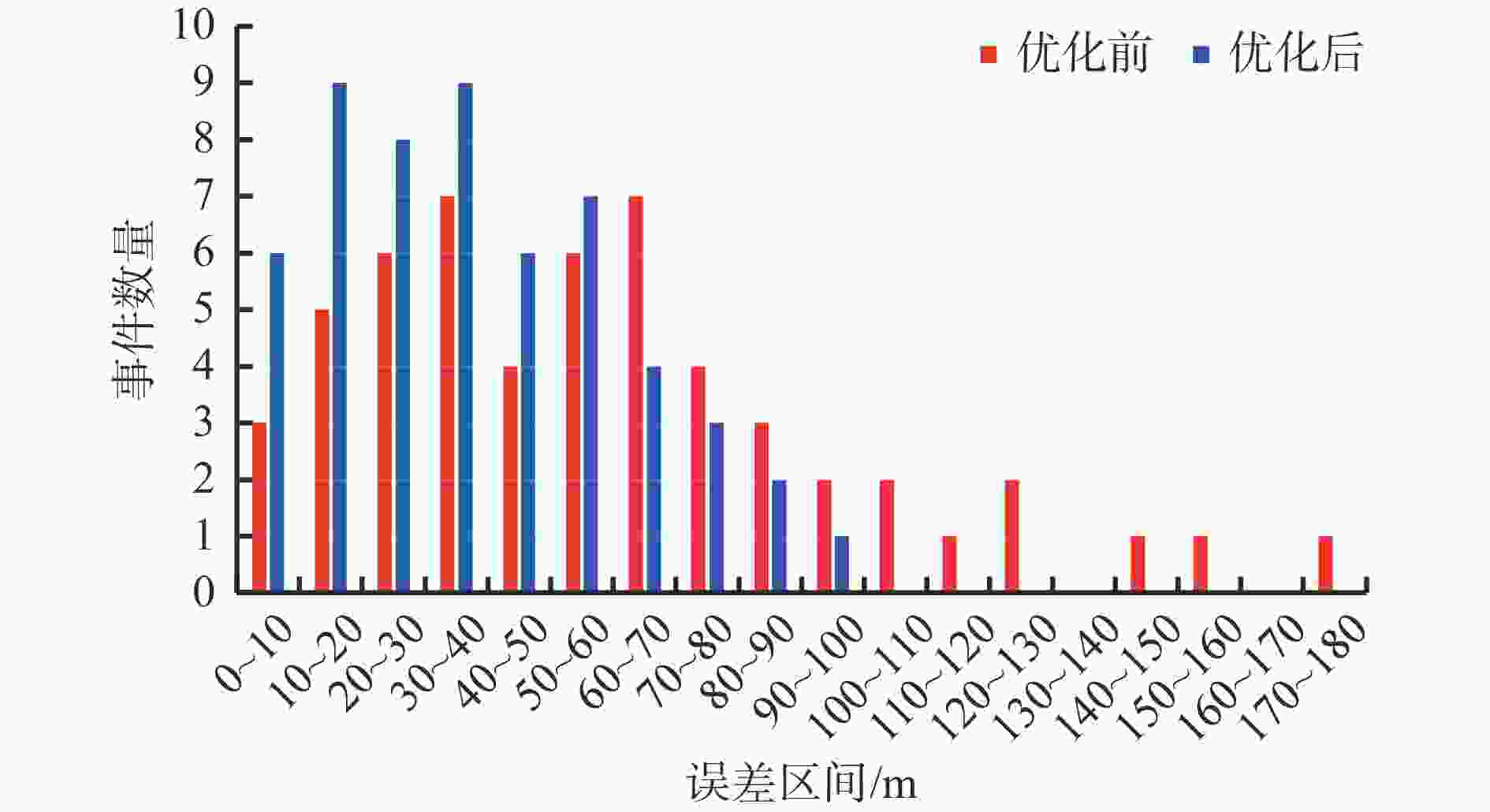

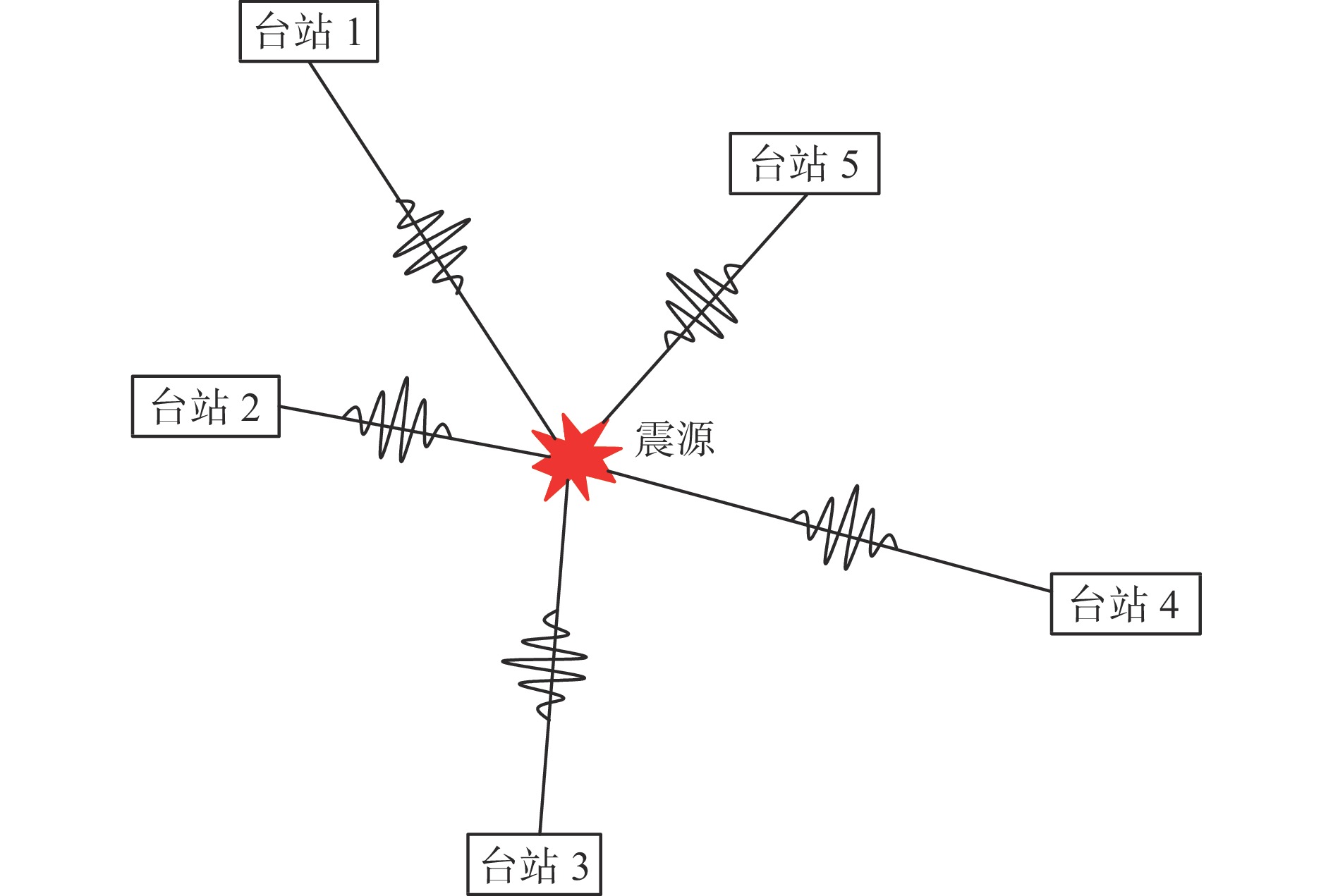

摘要: 微震监测台网的监测能力取决于多种因素,如台网布置、速度模型、震相读取误差、走时区域异常、定位算法、设备运行状态和环境噪声等,其中台网布置现阶段可以人为优化。为了对微震监测台网的监测能力进行有效评价,并在此基础上对台网布置进行优化,提出了一种煤矿微震监测台网监测能力分析与优化方法。分析了台网布置因素中对微震监测台网监测能力影响最大、最直接的四因素:有效波形数、最大空隙角、近台震中距和台站高差,指出有效波形数、近台震中距和台站高差对震源深度求解误差起决定性作用,有效波形数和最大空隙角对震中定位精度起决定性作用。结合现有台网和工作面情况,得出四因素的分布云图,通过四因素分布云图逐项对微震监测台网监测能力进行评价,根据评价结果进行优化,得出新的台网布置方案;对新方案进行定位误差与灵敏度分析,得出全矿井的震中定位误差、震源定位误差及区域灵敏度,对新方案进行二次评价;若二次评价结果满足要求,则可将新方案作为最佳台网布置方案;若二次评价结果不满足要求,则重新进行四因素分项评价并对方案进行优化,直至满足要求为止。现场试验结果表明,利用提出的方法对唐口煤矿5307工作面的微震监测台网进行优化后,爆破震源定位误差均值由59.2 m降到37.2 m,定位误差最大值降到100 m以下,误差在50 m以下的爆破事件占总数的69.0%,说明提出的方法能够有效提高微震定位精度,优化台网监测能力。Abstract: The monitoring capability of microseismic monitoring network depends on many factors, such as network layout, velocity model, seismic phase reading error, regional anomaly of travel time, positioning algorithm, equipment running state and environmental noise. Among these factors, the network layout can be artificially optimized at present stage. In order to effectively evaluate the monitoring capacity of microseismic monitoring network and optimize the network layout, the analysis and optimization method of monitoring capacity of coal mine microseismic monitoring network is proposed. This study analyzes four factors which have the greatest and most direct influence on the monitoring capability of the microseismic monitoring network. The four factors are the number of effective waveforms, the maximum gap angle, the near-station epicenter distance and the height difference between stations. It is pointed out that the number of effective waveforms, the near-station epicenter distance and the height difference between stations play a decisive role in the error of hypocenter depth solution. The number of effective waveforms and the maximum gap angle play a decisive role in the precision of epicenter positioning. According to the situation of the existing network and the working face, the distribution cloud pictures of the four factors are obtained. The monitoring capability of the microseismic network is evaluated item by item through the distribution cloud pictures of the four factors. The new network arrangement scheme is obtained through optimization of the evaluation result. The positioning error and sensitivity of the new scheme are analyzed. The epicenter positioning error, hypocenter positioning error and regional sensitivity of the whole mine are obtained. The second evaluation of the new scheme is carried out. If the secondary evaluation results meet the requirements, the new scheme can be regarded as the best network layout scheme. If the secondary evaluation results do not meet the requirements, the four factors sub item evaluation will be carried out again and the scheme will be optimized until the requirements are met. The field test results show that after the proposed method is used to optimize the microseismic monitoring network of 5307 working face in Tangkou Coal Mine, the average value of blasting hypocenter positioning error is reduced from 59.2 m to 37.2 m. The maximum value of positioning error is reduced to less than 100 m, and the blasting events with error less than 50 m account for 69.0% of the total. The results show that the proposed method can effectively improve the microseismic positioning precision and optimize the monitoring capability of the network.

-

表 1 2种情况下的台站坐标

Table 1. Station coordinates in 2 cases

m 台站编号 台站无高差 台站高差合理 xi yi zi xi yi zi 1 470 450 −600 470 450 −500 2 770 450 −600 770 450 −550 3 1070 450 −600 1070 450 −600 4 1370 550 −600 1370 550 −650 5 1070 650 −600 1070 650 −700 6 770 650 −600 770 650 −560 7 470 650 −600 470 650 −620 表 2 台网监测能力分级评价结论与改进措施

Table 2. Classification evaluation conclusions and improvement measures of network monitoring capability

研究项 评价结论 改进措施 有效波形数 台站数少 增加3个台站 最大空隙角 单侧布置 工作面后方增加S7,S8 近台震中距 低值区小 工作面前方增加S6 台站高差 需要扩大 S7,S8位于630轨道大巷内 表 3 优化前后台站坐标

Table 3. Station coordinates before and after optimization

m 阶段 台站 xi yi zi 优化前 T1 39452767 3921063 −901 T2 39452911 3920964 −891 T3 39452743 3920849 −903 S4 39452750 3920312 −958 S5 39453116 3920053 −964 优化后 T1 39452767 3921063 −901 T2 39453037 3920889 −888 T3 39452743 3920849 −903 S4 39452750 3920312 −958 S5 39453116 3920053 −964 S6 39453076 3920616 −889 S7 39452123 3920745 −958 S8 39451613 3921114 −949 表 4 震源定位误差对比

Table 4. Comparison of hypocenter positioning error

对比项 误差

均值/m误差

标准差/m误差

最大值/m误差≤50 m

事件占比/%优化前 59.2 38.7 175 45.5 优化后 37.2 23.2 96 69.0 改进度/% 37.2 40.1 45.1 51.6 -

[1] 姜福兴,杨淑华,成云海,等. 煤矿冲击地压的微地震监测研究[J]. 地球物理学报,2006,49(5):1511-1516. doi: 10.3321/j.issn:0001-5733.2006.05.032JIANG Fuxing,YANG Shuhua,CHENG Yunhai,et al. A study on microseismic monitoring of rock burst in coal mine[J]. Chinese Journal of Geophysics,2006,49(5):1511-1516. doi: 10.3321/j.issn:0001-5733.2006.05.032 [2] 徐奴文,唐春安,沙椿,等. 锦屏一级水电站左岸边坡微震监测系统及其工程应用[J]. 岩石力学与工程学报,2010,29(5):915-925.XU Nuwen,TANG Chun'an,SHA Chun,et al. Microseismic monitoring system establishment and its engineering applications to left bank slope of Jinping I Hydropower Station[J]. Chinese Journal of Rock Mechanics and Engineering,2010,29(5):915-925. [3] 巩思园,窦林名,曹安业,等. 煤矿微震监测台网优化布设研究[J]. 地球物理学报,2010,53(2):457-465. doi: 10.3969/j.issn.0001-5733.2010.02.025GONG Siyuan,DOU Linming,CAO Anye,et al. Study on optimal configuration of seismological observation network for coal mine[J]. Chinese Journal of Geophysics,2010,53(2):457-465. doi: 10.3969/j.issn.0001-5733.2010.02.025 [4] 唐礼忠,杨承祥,潘长良. 大规模深井开采微震监测系统站网布置优化[J]. 岩石力学与工程学报,2006,25(10):2036-2042. doi: 10.3321/j.issn:1000-6915.2006.10.014TANG Lizhong,YANG Chengxiang,PAN Changliang. Optimization of microseismic monitoring network for large-scale deep well mining[J]. Chinese Journal of Rock Mechanics and Engineering,2006,25(10):2036-2042. doi: 10.3321/j.issn:1000-6915.2006.10.014 [5] 邱宇,蒋长胜,司政亚. 地震监测台网优化布局技术方法综述[J]. 地球物理学进展,2020,35(3):866-873. doi: 10.6038/pg2020DD0069QIU Yu,JIANG Changsheng,SI Zhengya. Summary of technical methods for optimizing layout of seismic monitoring network[J]. Progress in Geophysics,2020,35(3):866-873. doi: 10.6038/pg2020DD0069 [6] 李楠,王恩元,李保林,等. 传感器台网布设对震源定位的影响规律及机制研究[J]. 中国矿业大学学报,2017,46(2):229-236.LI Nan,WANG Enyuan,LI Baolin,et al. Research on the influence law and mechanisms of sensors network layouts for the source location[J]. Journal of China University of Mining & Technology,2017,46(2):229-236. [7] 曹英莉,刘玉桥,邓红卫. 矿山微震监测台网多目标优化决策模型研究及应用[J]. 矿业研究与开发,2021,41(11):34-43.CAO Yingli,LIU Yuqiao,DENG Hongwei. Research and application on multi-objective optimization decision model for mine microseismic monitoring network[J]. Mining Research and Development,2021,41(11):34-43. [8] 崔宇,李夕兵,董陇军,等. 玲珑金矿微震监测台网布设优化[J]. 黄金科学技术,2019,27(3):417-424.CUI Yu,LI Xibing,DONG Longjun,et al. Optimization of micro-seismic monitoring network layout in Linglong Gold Mine[J]. Gold Science and Technology,2019,27(3):417-424. [9] 梁姗姗,邹立晔,赵博,等. 中国测震台网地震监测能力初步分析[J]. 地震地磁观测与研究,2021,42(6):68-75. doi: 10.3969/j.issn.1003-3246.2021.06.010LIANG Shanshan,ZOU Liye,ZHAO Bo,et al. Preliminary analysis of seismic monitoring capability of China Seismic Network[J]. Seismological and Geomagnetic Observation and Research,2021,42(6):68-75. doi: 10.3969/j.issn.1003-3246.2021.06.010 [10] 胡先明,邵玉平. 水库地震台网监测能力计算方法−基于G−R关系式[J]. 地震地质,2010,32(4):647-655. doi: 10.3969/j.issn.0253-4967.2010.04.012HU Xianming,SHAO Yuping. Calculation method of monitoring capability of reservoir seismic network:based on G-R relationship[J]. Seismology and Geology,2010,32(4):647-655. doi: 10.3969/j.issn.0253-4967.2010.04.012 [11] 徐刚,陈法兵,张振金,等. 井上下微震联合监测震源垂直定位精度优化研究[J]. 煤炭科学技术,2020,48(2):80-88.XU Gang,CHEN Fabing,ZHANG Zhenjin,et al. Study on optimization of vertical location accuracy of seismic source based on joint monitoring of surface and underground micro-seismic monitoring[J]. Coal Science and Technology,2020,48(2):80-88. [12] 蔡永顺,张龙,张达,等. 基于Sigma−Optimal方法的微震监测台网设计及优化[J]. 有色金属(矿山部分),2019,71(1):79-84. doi: 10.3969/j.issn.1671-4172.2019.01.016CAI Yongshun,ZHANG Long,ZHANG Da,et al. Design and optimization of microseismic monitoring network based on Sigma-Optimal method[J]. Nonferrous Metals(Mining Section),2019,71(1):79-84. doi: 10.3969/j.issn.1671-4172.2019.01.016 [13] 陈法兵. 矿山微震定位子台网的分布对定位精度的影响[J]. 煤矿开采,2016,21(4):107-114.CHEN Fabing. Influence of mine microseism location sub network distribution to positioning precision[J]. Coal Mining Technology,2016,21(4):107-114. -

下载:

下载: