Fault diagnosis of mine drainage system based on fuzzy Bayesian network

-

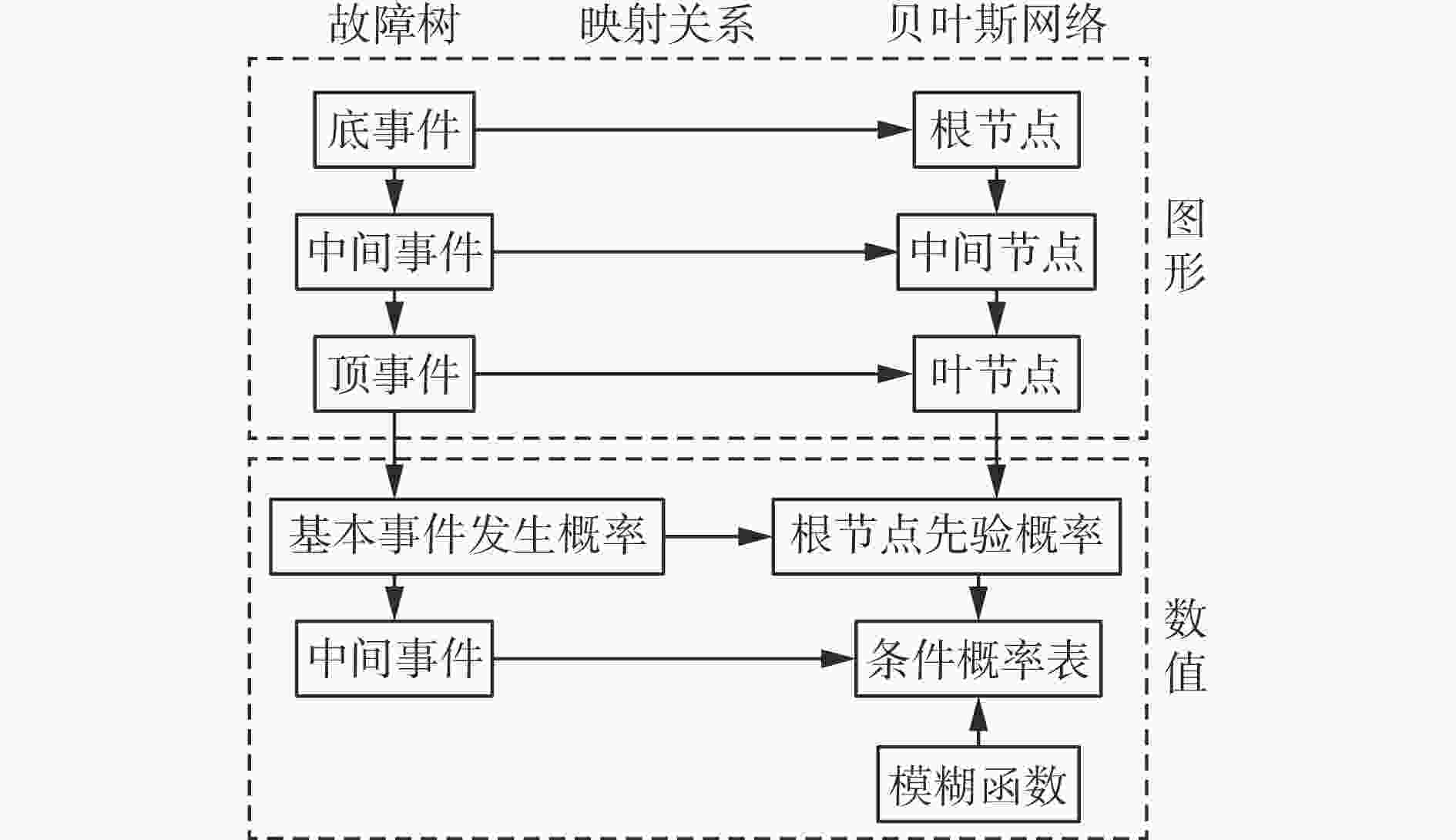

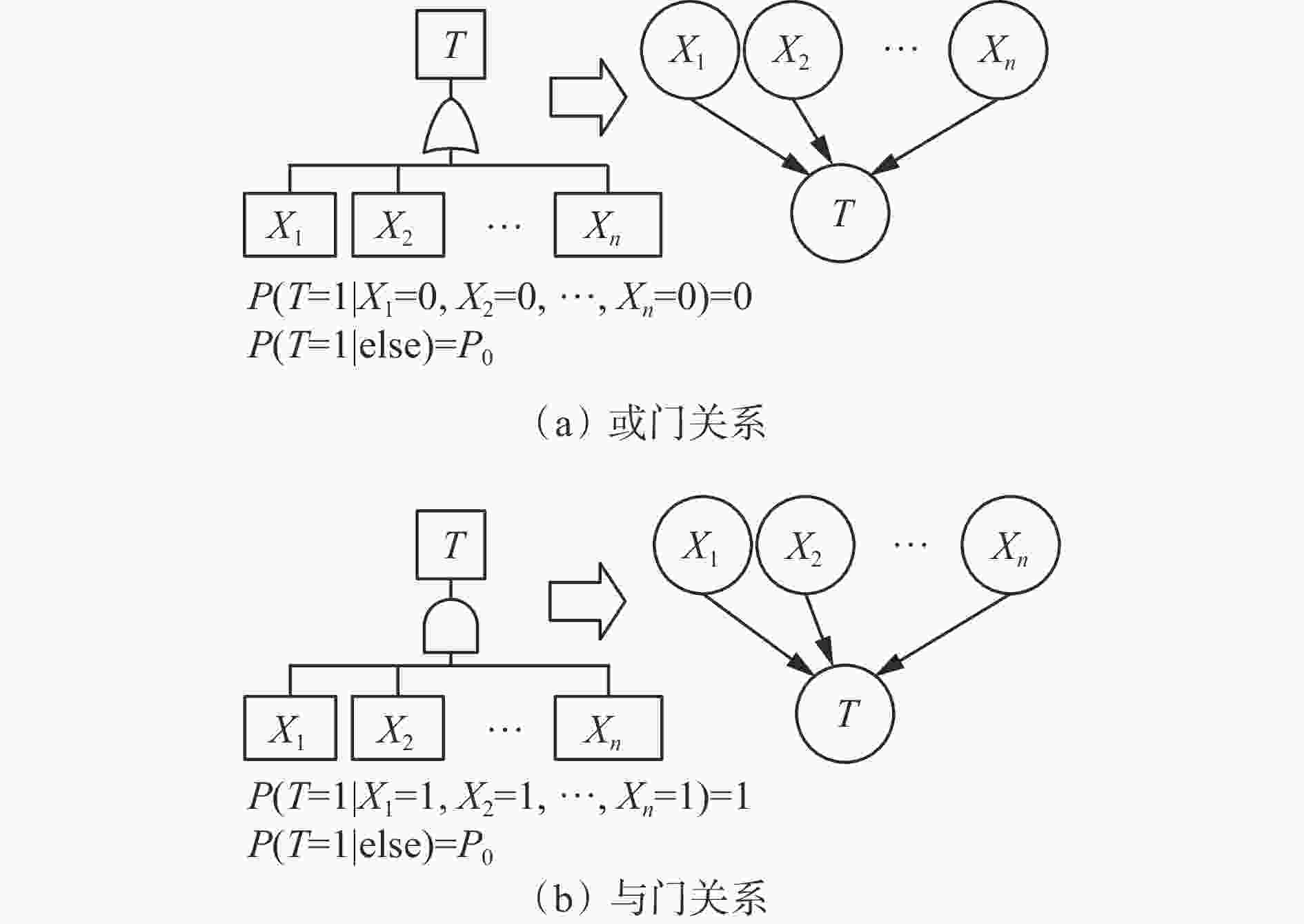

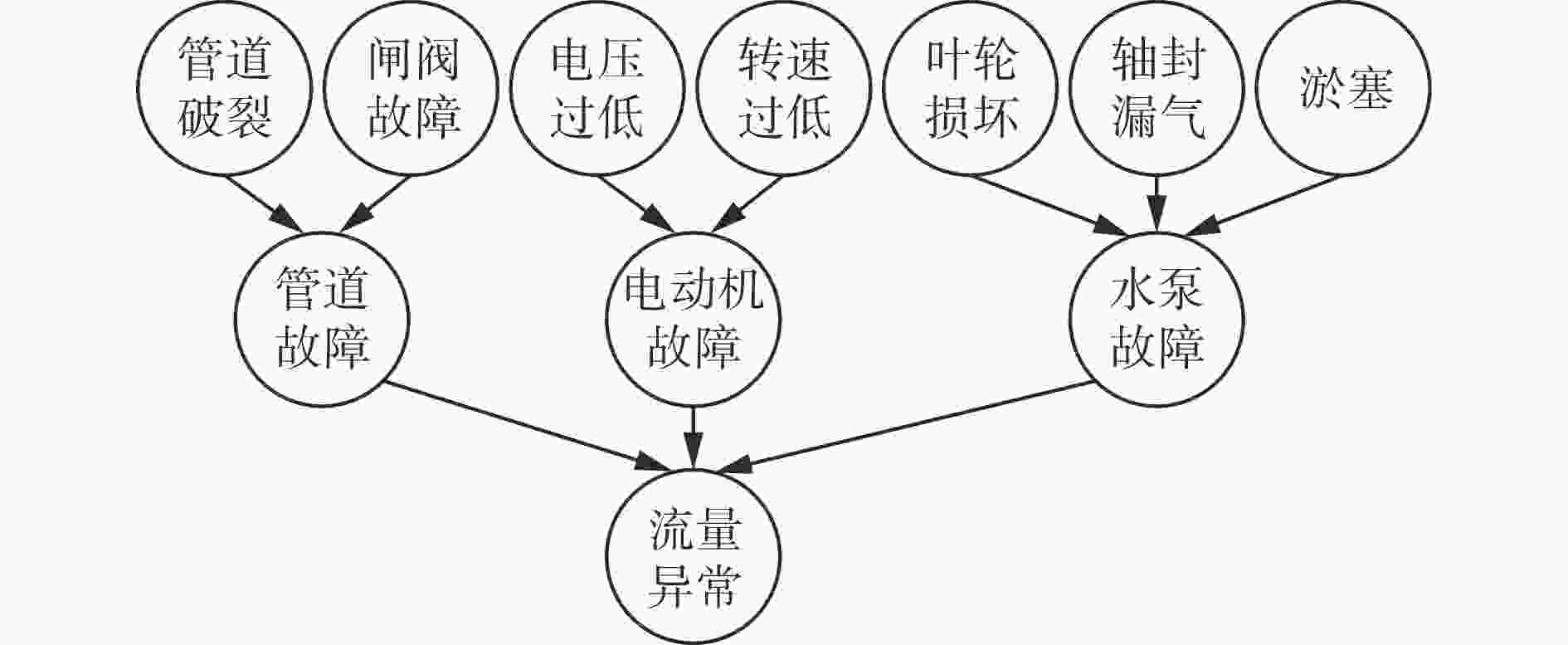

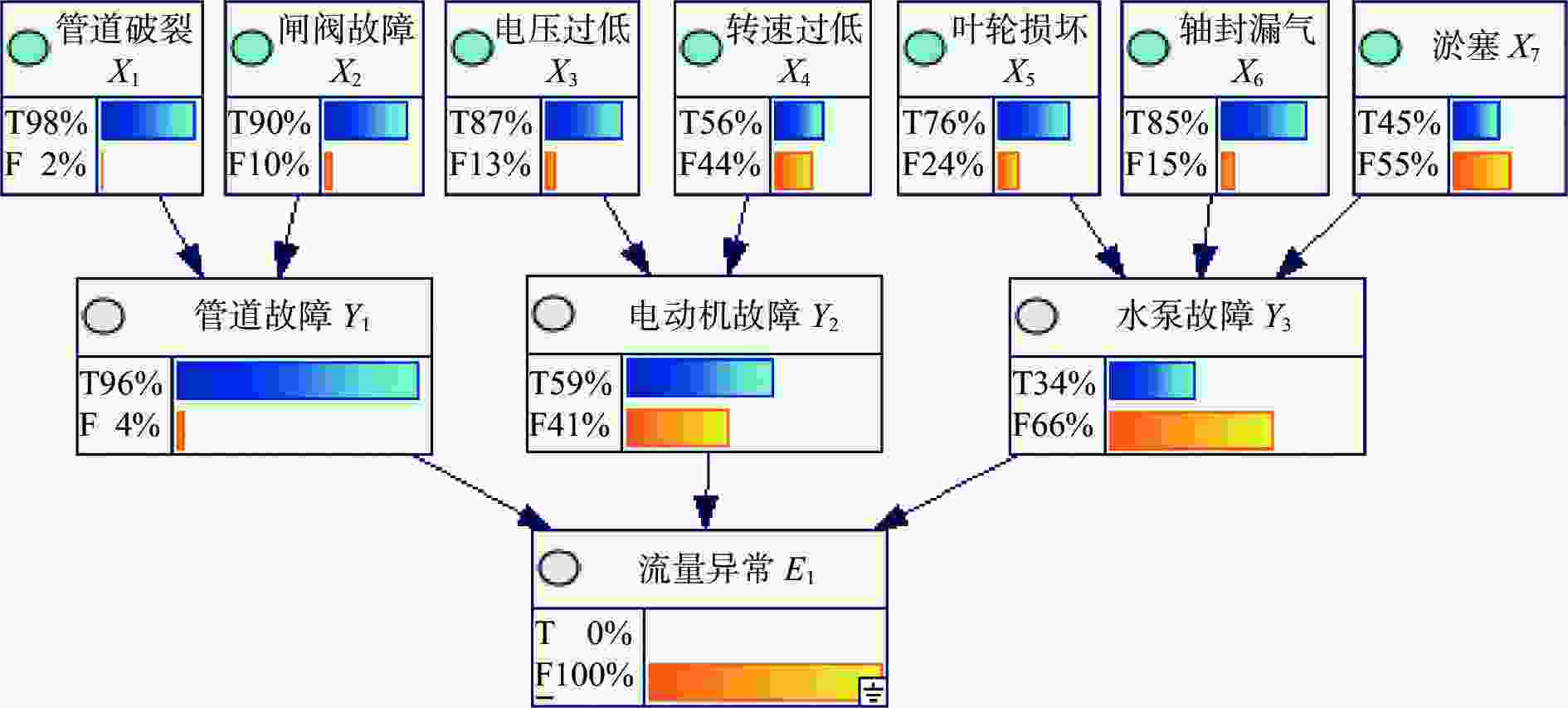

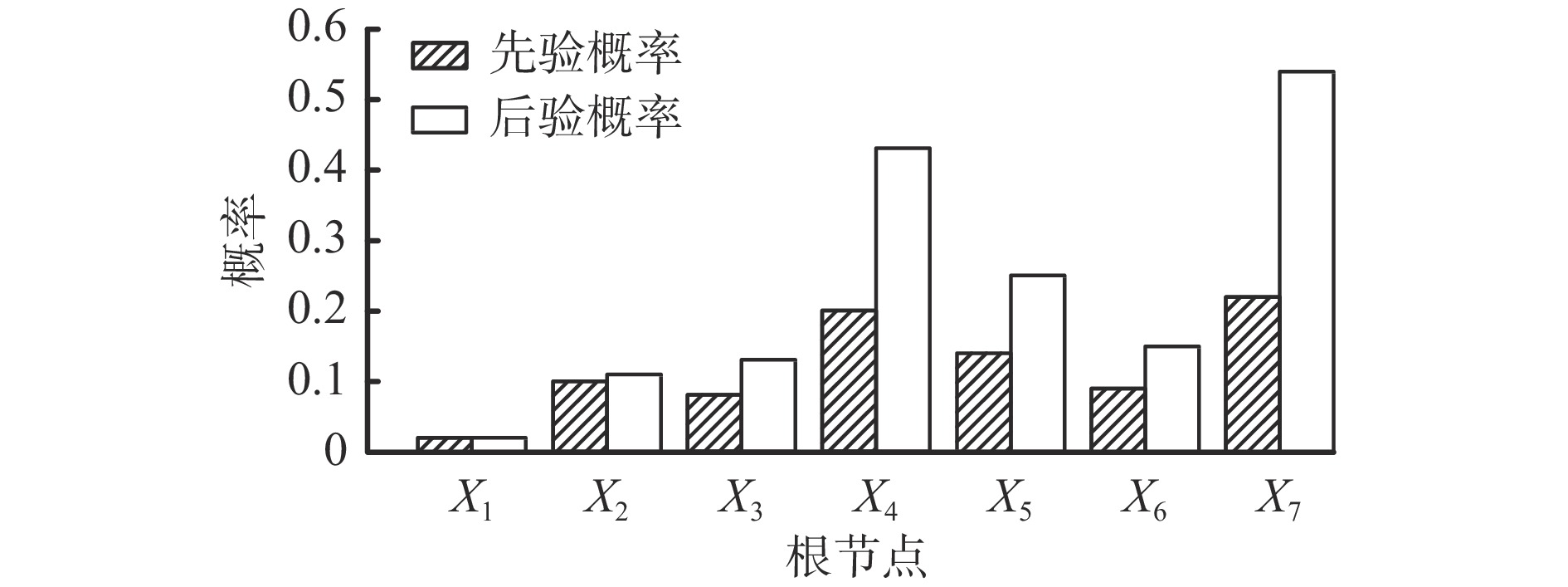

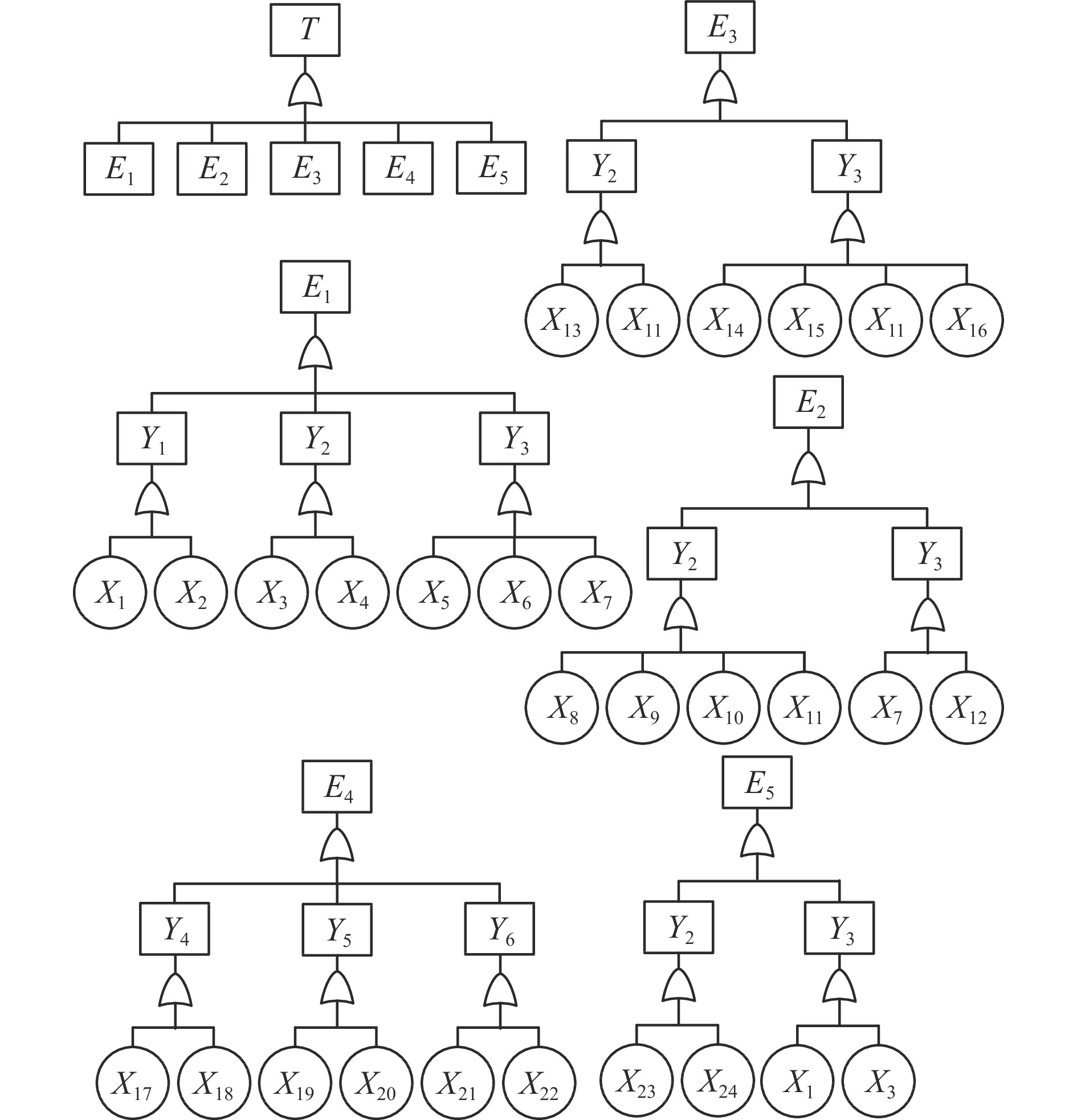

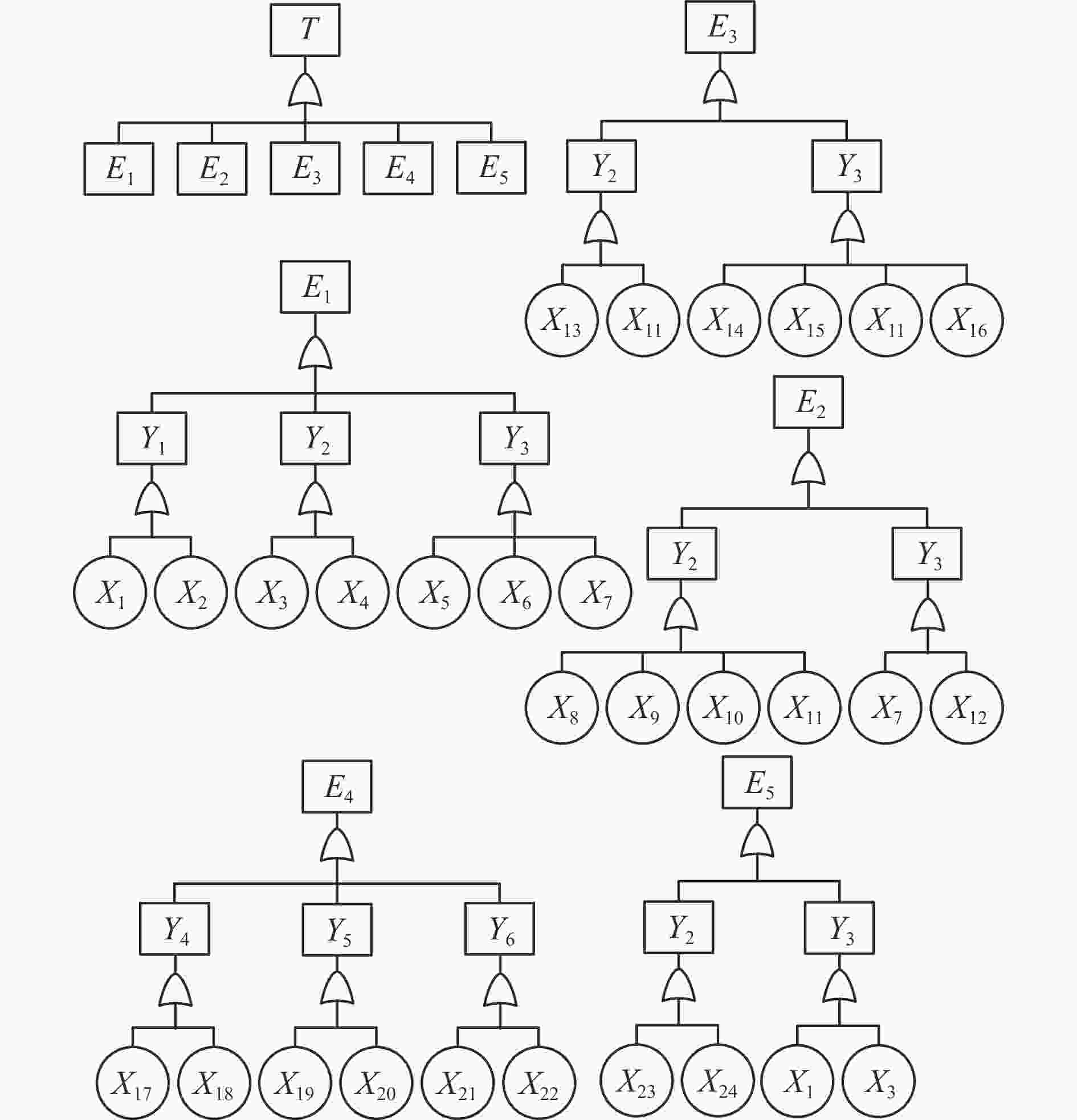

摘要: 矿井排水系统不断向自动化、智能化方向发展,系统结构和功能越来越复杂,单一部件的功能异常和故障问题可能会造成整个系统故障。针对现有矿井排水系统故障诊断方法实施难度较大、未考虑系统的整体性、故障诊断效率低等问题,提出一种基于模糊贝叶斯网络的矿井排水系统故障诊断方法。首先,利用故障树分析法将系统的故障原因逐层分解细化,找出系统故障的根本原因。其次,将故障树中的事件转换为贝叶斯网络的节点,逻辑门转换为贝叶斯网络的有向边及条件概率,根据故障树与贝叶斯网络之间的映射关系构建贝叶斯网络。然后,将模糊集合理论引入贝叶斯网络中,通过专家评估确定故障与征兆间的关联强度,经三角模糊数模糊化、均值化、去模糊化处理,得到模糊贝叶斯网络的条件概率。最后,根据先验概率和条件概率,利用模糊贝叶斯网络判断各根节点的故障概率。利用Genie3.0仿真软件建立模糊贝叶斯网络并进行推理分析和诊断测试,结果表明,该方法对各故障征兆的诊断准确率均在80%以上,平均准确率为82.7%。该方法不仅能确定故障源的具体位置和具体部件,还能找出矿井排水系统的薄弱点,排除潜在故障,提升系统的可靠性与安全性。Abstract: The mine drainage system is developing towards automation and intelligence. The system's structure and function are becoming more and more complex, and the abnormal function and failure of a single component may cause the failure of the whole system. The existing fault diagnosis methods of the mine drainage system have problems, such as difficult implementation, no consideration of the integrity of the system, and low fault diagnosis efficiency. In order to solve the above problems, a fault diagnosis method of mine drainage system based on fuzzy Bayesian network is proposed. Firstly, the fault tree analysis method is used to decompose the fault causes of the system layer by layer, and find out the root cause of the system fault. Secondly, the events in the fault tree are transformed into the nodes of the Bayesian network. The logic gates are transformed into the directed edges and conditional probabilities of the Bayesian network. The Bayesian network is constructed according to the mapping relationship between the fault tree and the Bayesian network. Thirdly, the fuzzy set theory is introduced into the Bayesian network. The correlation strength between fault and symptom is determined by expert evaluation. After fuzzification by triangular fuzzy number, averaging and defuzzification, the conditional probability of the fuzzy Bayesian network is obtained. Finally, according to the prior probability and conditional probability, the fuzzy Bayesian network is used to judge the probability of each root node fault. The simulation software Genie3.0 is used to establish the fuzzy Bayesian network, and the reasoning analysis and diagnosis test are carried out. The results show that the diagnosis accuracy of the method for each fault symptom is above 80%, and the average accuracy is 82.7%. The method can not only determine the specific position and specific components of the fault source, but also find out the weak nodes of the mine drainage system, eliminate potential faults, and improve the reliability and safety of the system.

-

Key words:

- mine drainage /

- fault diagnosis /

- fuzzy Bayesian network /

- fault tree /

- fuzzy set theory /

- triangular fuzzy number /

- expert evaluation

-

表 1 矿井排水系统故障树各符号意义

Table 1. Significance of symbols of fault tree of mine drainage system

符号 故障 符号 故障 T 排水系统故障 X7 淤塞 E1 流量异常 X8 散热不良 E2 温度异常 X9 润滑不良 E3 振动信号异常 X10 短路 E4 负压不足 X11 轴承故障 E5 正压不足 X12 叶轮卡死 Y1 管道故障 X13 联轴器故障 Y2 电动机故障 X14 紧固件松动 Y3 水泵故障 X15 水泵汽蚀 Y4 压力水故障 X16 水泵轴故障 Y5 射流装置故障 X17 管道缺水 Y6 真空管道故障 X18 引水阀故障 X1 管道破裂 X19 射流阀故障 X2 闸阀故障 X20 射流器故障 X3 电压过低 X21 真空阀故障 X4 转速过低 X22 真空管堵塞 X5 叶轮损坏 X23 电动机卡死 X6 轴封漏气 X24 电动机缺相 表 2 语言变量与三角模糊数之间的对应关系

Table 2. Correspondence between linguistic variables and triangular fuzzy numbers

序号 语言变量 符号 三角模糊数 1 很低 VL (0,0,0.2) 2 低 L (0.1,0.2,0.4) 3 中等 M (0.3,0.5,0.7) 4 高 H (0.6,0.8,0.9) 5 很高 VH (0.8,1.0,1.0) 表 3 各根节点的先验概率

Table 3. The prior probability of each root node

故障 符号 先验概率 管道破裂 X1 0.02 闸阀故障 X2 0.10 电压过低 X3 0.08 转速过低 X4 0.20 叶轮损坏 X5 0.14 轴封漏气 X6 0.09 淤塞 X7 0.22 表 4 专家评估结果

Table 4. Expert evaluation results

条件概率 专家评估结果 专家1 专家2 专家3 专家4 P(Y1=1|X1=1,X2=0) VL VL M VL P(Y1=1|X1=0,X2=1) L M L L P(Y2=1|X3=0,X4=1) M L M M P(Y2=1|X3=1,X4=0) VL L L VL P(Y3=1|X6=0,X7=0,X5=1) L M L VL P(Y3=1|X6=0,X7=1,X5=0) M M L M P(Y3=1|X6=0,X7=1,X5=1) M H M M P(Y3=1|X6=1,X7=0,X5=0) L VL VL L P(Y3=1|X6=1,X7=0,X5=1) L L VL VL P(Y3=1|X6=1,X7=1,X5=0) VH M H VH P(E1=1|Y1=0,Y2=0,Y3=1) VH H M H P(E1=1|Y1=0,Y2=1,Y3=0) L H M H P(E1=1|Y1=0,Y2=1,Y3=1) M VH VH VH P(E1=1|Y1=1,Y2=0,Y3=0) L L VL VL P(E1=1|Y1=1,Y2=0,Y3=1) VL L L M P(E1=1|Y1=1,Y2=1,Y3=0) M M L M 表 5 各叶节点的条件概率

Table 5. Conditional probability of each leaf node

故障 故障征兆 条件概率 X2;X1 Y1 P(Y1=1|X1=1,X2=0)=0.1625 X2;X1 Y1 P(Y1=1|X1=0,X2=1)=0.3125 X3;X4 Y2 P(Y2=1|X3=0,X4=1)=0.4375 X3;X4 Y2 P(Y2=1|X3=1,X4=0)=0.1500 X6;X7;X5 Y3 P(Y3=1|X6=0,X7=0,X5=1)=0.2625 X6;X7;X5 Y3 P(Y3=1|X6=0,X7=1,X5=0)=0.4375 X6;X7;X5 Y3 P(Y3=1|X6=0,X7=1,X5=1)=0.5625 X6;X7;X5 Y3 P(Y3=1|X6=1,X7=0,X5=0)=0.1500 X6;X7;X5 Y3 P(Y3=1|X6=1,X7=0,X5=1)=0.1500 X6;X7;X5 Y3 P(Y3=1|X6=1,X7=1,X5=0)=0.7875 Y1;Y2;Y3 E1 P(E1=1|Y1=0,Y2=0,Y3=1)=0.7375 Y1;Y2;Y3 E1 P(E1=1|Y1=0,Y2=1,Y3=0)=0.5625 Y1;Y2;Y3 E1 P(E1=1|Y1=0,Y2=1,Y3=1)=0.8375 Y1;Y2;Y3 E1 P(E1=1|Y1=1,Y2=0,Y3=0)=0.1500 Y1;Y2;Y3 E1 P(E1=1|Y1=1,Y2=0,Y3=1)=0.2625 Y1;Y2;Y3 E1 P(E1=1|Y1=1,Y2=1,Y3=0)=0.4375 表 6 故障诊断测试结果

Table 6. Fault diagnosis test results

故障征兆 诊断总次数 诊断正确次数 准确率/% 流量异常 72 60 83.3 振动信号异常 30 24 80.0 正压不足 35 30 85.7 负压不足 46 38 82.6 温度异常 54 44 81.5 -

[1] MEEGODA J N,JULIANO T M,POTTS L,et al. Implementation of a drainage information,analysis and management system[J]. Journal of Traffic and Transportation Engineering,2017,4(2):165-177. [2] MAJDI A,AMINI M,NASAB S K. Adequate drainage system design for heap leaching structures[J]. Journal of Hazardous Materials,2007,147(1/2):288-296. [3] 李海军, 马登武, 刘霄, 等. 贝叶斯网络理论在装备故障诊断中的应用[M]. 北京: 国防工业出版社, 2009.LI Haijun, MA Dengwu, LIU Xiao, et al. Application of Bayesian network theory in equipment fault diagnosis[M]. Beijing: National Defense Industry Press, 2009. [4] 张伟元,张朋飞,潘越,等. 基于正压给水的矿井自动排水控制系统[J]. 煤矿安全,2020,51(2):128-131. doi: 10.13347/j.cnki.mkaq.2020.02.029ZHANG Weiyuan,ZHANG Pengfei,PAN Yue,et al. Automatic drainage control system of coal mine based on positive pressure water supply[J]. Safety in Coal Mines,2020,51(2):128-131. doi: 10.13347/j.cnki.mkaq.2020.02.029 [5] 董铮. 机械故障诊断基础研究“何去何从”[J]. 科技创新导报,2017,14(32):21,23. doi: 10.16660/j.cnki.1674-098X.2017.32.021DONG Zheng. "Where to go" for basic research on mechanical fault diagnosis[J]. Science and Technology Innovation Herald,2017,14(32):21,23. doi: 10.16660/j.cnki.1674-098X.2017.32.021 [6] 魏晶. 具有故障自诊断功能的矿井节能排水控制系统[J]. 煤矿机电,2019,40(6):104-106. doi: 10.16545/j.cnki.cmet.2019.06.030WEI Jing. Energy-saving and drainage control system of mine with fault self-diagnosis function[J]. Colliery Mechanical & Electrical Technology,2019,40(6):104-106. doi: 10.16545/j.cnki.cmet.2019.06.030 [7] 赵丽娜,赵倩,宋保健. 基于Petri网的矿井排水系统多源信息故障诊断[J]. 电子技术,2018,47(5):73-76,72. doi: 10.3969/j.issn.1000-0755.2018.05.022ZHAO Lina,ZHAO Qian,SONG Baojian. Fault diagnosis of multi-source information of mine drainage system based on Petri net[J]. Electronic Technology,2018,47(5):73-76,72. doi: 10.3969/j.issn.1000-0755.2018.05.022 [8] 黄倩,黄强,鲁远祥,等. 基于LabVIEW的矿井排水装置故障监测系统的设计[J]. 工矿自动化,2011,37(5):8-11.HUANG Qian,HUANG Qiang,LU Yuanxiang,et al. Design of fault monitoring system of mine drainage device based on LabVIEW[J]. Industry and Mine Automation,2011,37(5):8-11. [9] 张志强,王嫣. 矿井排水计算机控制及故障诊断系统开发[J]. 煤炭技术,2014,33(1):59-61. doi: 10.13301/j.cnki.ct.2014.01.053ZHANG Zhiqiang,WANG Yan. Development of computer control and fault diagnosis system in coal mine drainage[J]. Coal Technology,2014,33(1):59-61. doi: 10.13301/j.cnki.ct.2014.01.053 [10] 张海峰. 矿井自动排水系统故障诊断技术研究与实现[D]. 北京: 煤炭科学研究总院, 2016.ZHANG Haifeng. Research and implementation on fault diagnosis for mine automatic drainage system [D]. Beijing: China Coal Research Institute, 2016. [11] CAI Baoping,HUANG Lei,XIE Min. Bayesian networks in fault diagnosis[J]. IEEE Transactions on Industrial Informatics,2017,13(5):2227-2240. doi: 10.1109/TII.2017.2695583 [12] 张梅,许桃,孙辉煌,等. 基于模糊故障树和贝叶斯网络的矿井提升机故障诊断[J]. 工矿自动化,2020,46(11):1-5,45. doi: 10.13272/j.issn.1671-251x.17562ZHANG Mei,XU Tao,SUN Huihuang,et al. Fault diagnosis of mine hoist based on fuzzy fault tree and Bayesian network[J]. Industry and Mine Automation,2020,46(11):1-5,45. doi: 10.13272/j.issn.1671-251x.17562 [13] 陈振阳,刘成刚,钱阳阳,等. 基于故障树分析的排风热回收空调系统故障诊断与应用[J]. 苏州科技大学学报(工程技术版),2019,32(1):19-22. doi: 10.3969/j.issn.1672-0679.2019.01.004CHEN Zhenyang,LIU Chenggang,QIAN Yangyang,et al. Application of fault diagnosis based on fault tree analysis for exhaust heat recovery air-conditioning system[J]. Journal of Suzhou University of Science and Technology(Engineering and Technology),2019,32(1):19-22. doi: 10.3969/j.issn.1672-0679.2019.01.004 [14] CHEN Ruwen, ZHU Songqing, HAO Fei, et al. Railway vehicle door fault diagnosis method with Bayesian network[C]. 2019 4th International Conference on Control and Robotics Engineering, Nanjing, 2019. [15] JUN H-B,KIM D. A Bayesian network-based approach for fault analysis[J]. Express Systems with Applications,2017,81:332-348. doi: 10.1016/j.eswa.2017.03.056 [16] 陈洪转,赵爱佳,李腾蛟,等. 基于故障树的复杂装备模糊贝叶斯网络推理故障诊断[J]. 系统工程与电子技术,2021,43(5):1248-1261. doi: 10.12305/j.issn.1001-506X.2021.05.12CHEN Hongzhuan,ZHAO Aijia,LI Tengjiao,et al. Fuzzy Bayesian network inference fault diagnosis of complex equipment based on fault tree[J]. Systems Engineering and Electronics,2021,43(5):1248-1261. doi: 10.12305/j.issn.1001-506X.2021.05.12 [17] ZHANG Guohua,CHEN Wu,JIAO Yuyong,et al. A failure probability evaluation method for collapse of drill-and-blast tunnels based on multistate fuzzy Bayesian network[J]. Engineering Geology,2020,276:105752. doi: 10.1016/j.enggeo.2020.105752 [18] 叶银芳,李登峰,余高锋. 需求为三角模糊数的联合订货模型及其成本分摊方法[J]. 系统科学与数学,2019,39(7):1142-1158. doi: 10.12341/jssms13669YE Yinfang,LI Dengfeng,YU Gaofeng. A joint replenishment model with demands represented by triangular fuzzy numbers and its cost allocation method[J]. Journal of Systems Science and Mathematical Sciences,2019,39(7):1142-1158. doi: 10.12341/jssms13669 [19] 徐双蝶,张焰,苏运. 考虑不确定性变量模糊相关性的智能配电网概率潮流计算[J]. 电网技术,2020,44(4):1488-1500. doi: 10.13335/j.1000-3673.pst.2019.0423XU Shuangdie,ZHANG Yan,SU Yun. Probabilistic power flow calculation in smart distribution networks considering fuzzy correlation between uncertainty variables[J]. Power System Technology,2020,44(4):1488-1500. doi: 10.13335/j.1000-3673.pst.2019.0423 [20] 关茹男. 基于语言型Z−Numbers的多属性决策研究[D]. 太原: 山西大学, 2021.GUAN Runan. Research on multi-attribute decision making based on linguistic Z-Numbers[D]. Taiyuan: Shanxi University, 2021. [21] 曾强,黄政,魏曙寰. 基于模糊理论和贝叶斯网络的燃气轮机健康状态评估方法[J]. 科学技术与工程,2020,20(11):4363-4369. doi: 10.3969/j.issn.1671-1815.2020.11.023ZENG Qiang,HUANG Zheng,WEI Shuhuan. Assessment method of gas turbine health based on fuzzy theory and Bayesian network[J]. Science Technology and Engineering,2020,20(11):4363-4369. doi: 10.3969/j.issn.1671-1815.2020.11.023 [22] 王金鑫,王忠巍,马修真,等. 基于贝叶斯网络的柴油机润滑系统多故障诊断[J]. 控制与决策,2019,34(6):1187-1194.WANG Jinxin,WANG Zhongwei,MA Xiuzhen,et al. Diagnosis of multiple faults of diesel engine lubrication system based on Bayesian networks[J]. Control and Decision,2019,34(6):1187-1194. [23] HUANG Yingping,MCMURRAN R,DHADYALLA G,et al. Probability based vehicle fault diagnosis:Bayesian network method[J]. Journal of Intelligent Manufacturing,2008,19(3):301-311. doi: 10.1007/s10845-008-0083-7 -

下载:

下载: