Manual regulation and control decision model of middle hydraulic support cluster automation in the intelligent working face

-

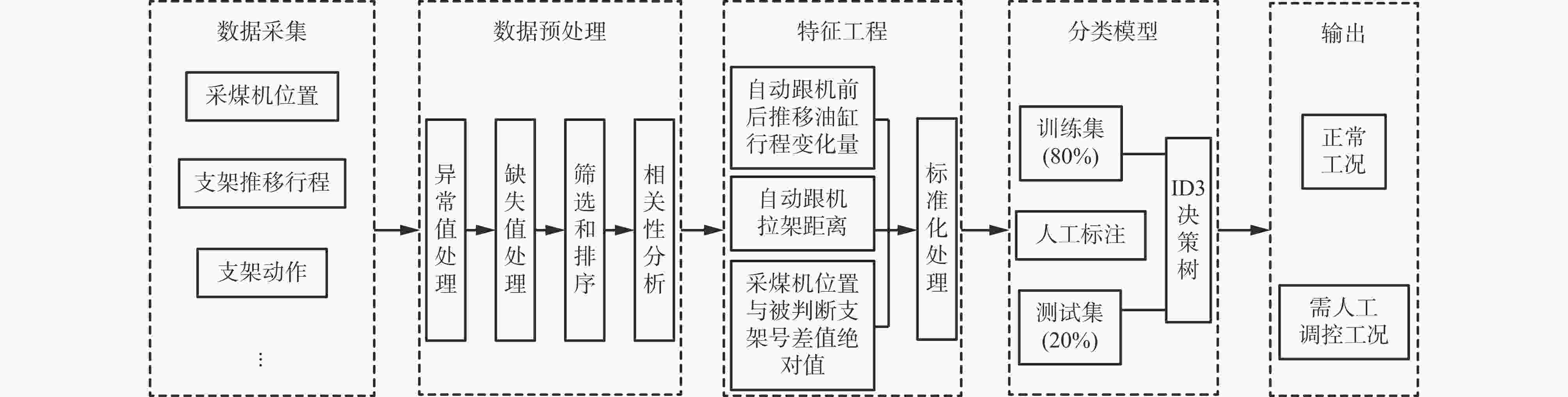

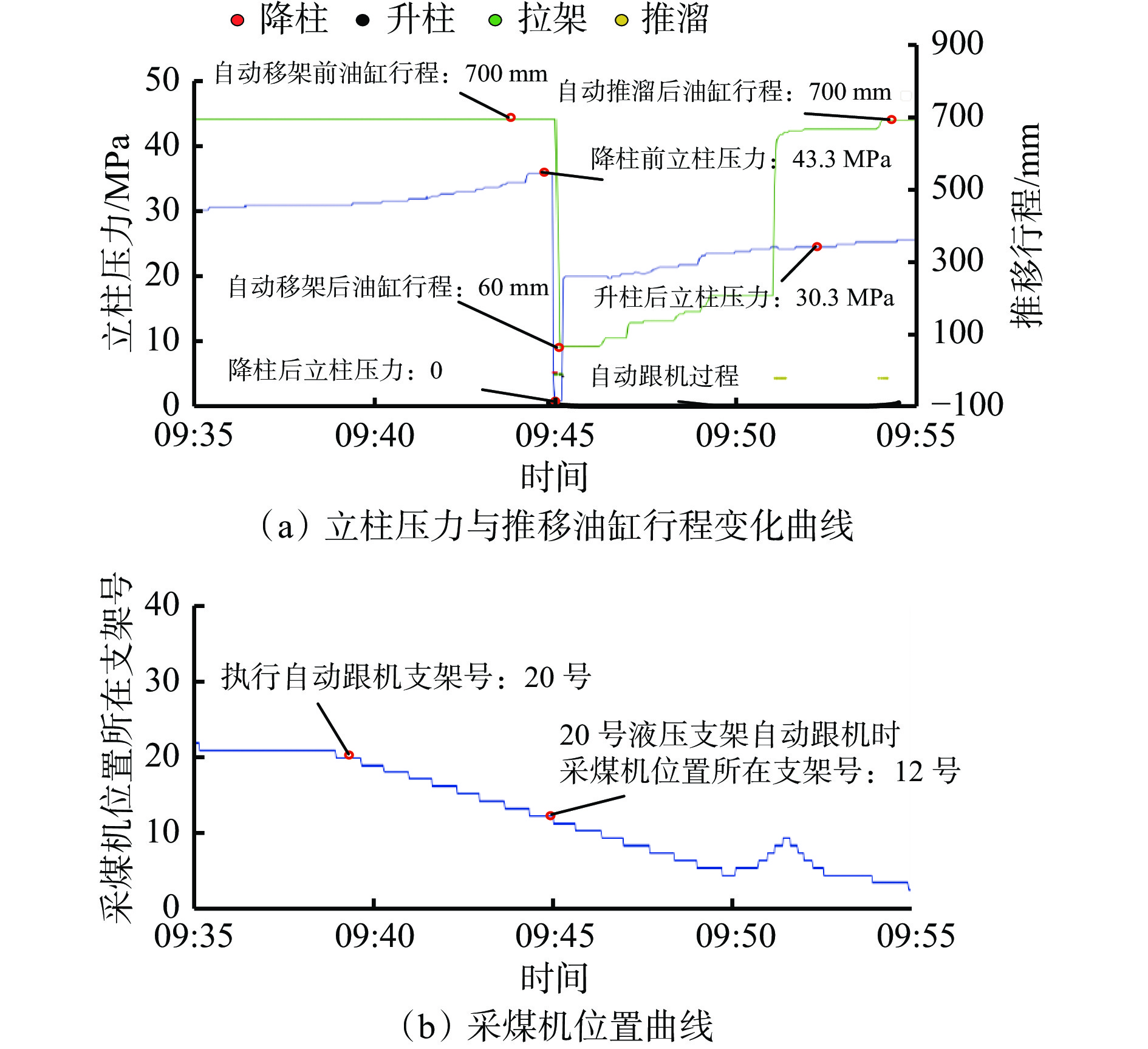

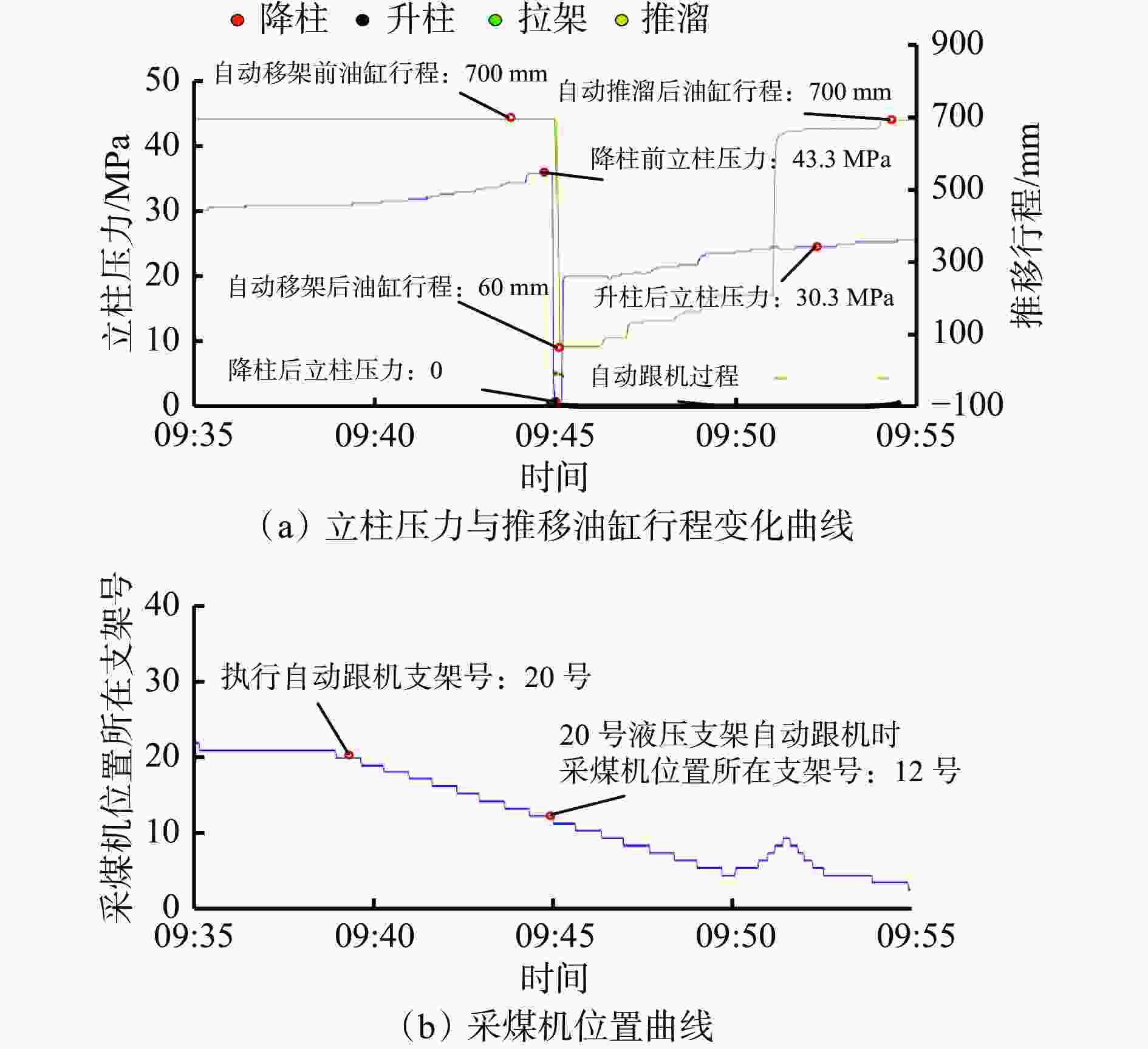

摘要: 智采工作面在液压支架自动跟机完成后,会出现丢架、直线度不平整、支架歪斜等异常工况,需要人工调控,目前研究缺乏对智采工作面生产过程中液压支架自动化后人工调控工况的知识发现,不利于工人快速判断需人工调控的液压支架架号。针对上述问题,从判别液压支架自动化后动作不达标液压支架架号出发,提出了一种智采工作面中部液压支架集群自动化后人工调控决策模型。 首先,对工作面历史数据进行分析,得出液压支架自动跟机完成后3个特征值(即自动跟机拉架距离、自动跟机前后的推移油缸行程变化量、采煤机位置支架号与被判断支架号的绝对差值)可作为判别液压支架自动跟机后是否进行人工调控的重要特征。根据上述结论,给出了液压支架集群自动化后人工调控决策模型结构,其中数据采集模块用于提供原始数据;数据预处理模块对原始数据进行异常值处理、筛选、排序和相关性分析等数据准备工作;特征工程模块对上述3个特征值进行计算及标准化处理,为分类模型提供样本集;分类模型对样本集进行划分后,利用ID3决策树进行分类,最后输出正常工况下的液压支架架号与需人工调控的液压支架架号。模型评估结果表明,与传统K最近邻(KNN)、支持向量机(SVM)、逻辑回归(LR)等分类算法相比,基于ID3决策树的智采工作面中部液压支架工况分类模型的训练集准确率为92.27%,测试集准确率为93.75%,能够较好地判别自动化后人工调控液压支架架号。Abstract: The intelligent working face has abnormal working conditions such as lost support, uneven straightness, and support skew after the automatic following of hydraulic support. Therefore, manual regulation and control are needed. At present, the research lacks the knowledge discovery of manual regulation and control working conditions after the hydraulic support automation in the production process of the intelligent working face. This is not conducive for workers to quickly judge the number of hydraulic support requiring manual regulation and control. In order to solve the above problems, based on the identification of the number of hydraulic support that is not up to the standard after the hydraulic support automation, a manual regulation and control decision model of middle hydraulic support cluster automation in the intelligent working face is put forward. Firstly, the historical data of the working face is analyzed. It is concluded that after the automatic following of the hydraulic support is finished, three characteristic values can be used as important characteristics for judging whether the hydraulic support carries out manual regulation and control after the automatic following of the hydraulic support. The characteristic values include the distance of the automatic following of the hydraulic support, the stroke variation of the pushing oil cylinder before and after the automatic following of the hydraulic support, and the absolute difference between the number of the hydraulic support at the position of the shearer and the number of the judged hydraulic support. According to the above conclusion, the structure of the manual control decision model after the hydraulic support cluster automation is proposed. The data acquisition module is used for providing the original data. The data preprocessing module prepares the original data by outlier processing, filtering, sorting and correlation analysis. The characteristic engineering module calculates and standardizes the above three characteristic values to provide a sample set for the classification model. After the classification model divides the sample set, the ID3 decision tree is used for classification. Finally, the number of hydraulic supports needing normal working conditions and the number of hydraulic supports nedeing manual control are output. The results of the model evaluation show that, compared with the traditional K-nearest neighbor (KNN), support vector machine (SVM), logical regression (LR) classification algorithms, the training set accuracy of the ID3 decision tree based classification model for the working conditions of hydraulic supports in the middle of the intelligent working face is 92.27%. The test set accuracy is 93.75%. The model can better distinguish the manual control hydraulic support number after automation.

-

表 1 样本数量统计

Table 1. Quantity statistics of samples

样本 样本数量 占比/% 正常工况样本 4 986 84.73 自动化后人工调控工况样本 899 15.27 表 2 模型准确率统计

Table 2. Model accuracy statistics

% 算法 训练集准确率 测试集准确率 决策树 92.27 93.75 KNN 91.51 91.82 SVM 93.84 90.82 LR 89.00 90.86 -

[1] 王国法,范京道,徐亚军,等. 煤炭智能化开采关键技术创新进展与展望[J]. 工矿自动化,2018,44(2):5-12.WANG Guofa,FAN Jingdao,XU Yajun,et al. Innovation progress and prospect on key technologies of intelligent coal mining[J]. Industry and Mine Automation,2018,44(2):5-12. [2] 王国法,庞义辉,任怀伟. 煤矿智能化开采模式与技术路径[J]. 采矿与岩层控制工程学报,2020,2(1):5-19.WANG Guofa,PANG Yihui,REN Huaiwei. Intelligent coal mining pattern and technological path[J]. Journal of Mining and Strata Control Engineering,2020,2(1):5-19. [3] 王国法,刘峰,庞义辉,等. 煤矿智能化−煤炭工业高质量发展的核心技术支撑[J]. 煤炭学报,2019,44(2):349-357.WANG Guofa,LIU Feng,PANG Yihui,et al. Coal mine intellectualization:the core technology of high quality development[J]. Journal of China Coal Society,2019,44(2):349-357. [4] 王国法. 煤矿智能化最新技术进展与问题探讨[J]. 煤炭科学技术,2022,50(1):1-27.WANG Guofa. New technological progress of coal mine intelligence and its problems[J]. Coal Science and Technology,2022,50(1):1-27. [5] 葛世荣,郝尚清,张世洪,等. 我国智能化采煤技术现状及待突破关键技术[J]. 煤炭科学技术,2020,48(7):28-46.GE Shirong,HAO Shangqing,ZHANG Shihong,et al. Status of intelligent coal mining technology and potential key technologies in China[J]. Coal Science and Technology,2020,48(7):28-46. [6] 王国法,徐亚军,张金虎,等. 煤矿智能化开采新进展[J]. 煤炭科学技术,2021,49(1):1-10.WANG Guofa,XU Yajun,ZHANG Jinhu,et al. New development of intelligent mining in coal mines[J]. Coal Science and Technology,2021,49(1):1-10. [7] 任怀伟,王国法,赵国瑞,等. 智慧煤矿信息逻辑模型及开采系统决策控制方法[J]. 煤炭学报,2019,44(9):2923-2935.REN Huaiwei,WANG Guofa,ZHAO Guorui,et al. Smart coal mine logic model and decision control method of mining system[J]. Journal of China Coal Society,2019,44(9):2923-2935. [8] 王国法,任怀伟,赵国瑞,等. 煤矿智能化十大“痛点”解析及对策[J]. 工矿自动化,2021,47(6):1-11.WANG Guofa,REN Huaiwei,ZHAO Guorui,et al. Analysis and countermeasures of ten'pain points' of intelligent coal mine[J]. Industry and Mine Automation,2021,47(6):1-11. [9] 张帅,任怀伟,韩安,等. 复杂条件工作面智能化开采关键技术及发展趋势[J]. 工矿自动化,2022,48(3):16-25. doi: 10.13272/j.issn.1671-251x.2021090041ZHANG Shuai,REN Huaiwei,HAN An,et al. Key technology and development trend of intelligent mining in complex condition working face[J]. Journal of Mine Automation,2022,48(3):16-25. doi: 10.13272/j.issn.1671-251x.2021090041 [10] 路正雄,郭卫,张帆,等. 基于数据驱动的综采装备协同控制系统架构及关键技术[J]. 煤炭科学技术,2020,48(7):195-205.LU Zhengxiong,GUO Wei,ZHANG Fan,et al. Collaborative control system architecture and key technologies of fully-mechanized mining equipment based on data drive[J]. Coal Science and Technology,2020,48(7):195-205. [11] ZHANG Lin,WANG Zhongbin,TAN Chao,et al. A fruit fly-optimized kalman filter algorithm for pushing distance estimation of a hydraulic powered roof support through tuning covariance[J]. Applied Sciences,2016,6(10):299. doi: 10.3390/app6100299 [12] FAN Qigao,LI Wei,WANG Yuqiao,et al. Control strategy for an intelligent shearer height adjusting system[J]. Mining Science & Technology(China),2010,20(6):908-912. [13] 牛剑峰. 受汽车无人驾驶启发的液压支架智能协同控制[J]. 工矿自动化,2020,46(5):54-56,75.NIU Jianfeng. Intelligent cooperative control of hydraulic support inspired by driveless car[J]. Industry and Mine Automation,2020,46(5):54-56,75. [14] 王统诚. 液压支架自动化跟机系统研究[D]. 青岛: 山东科技大学, 2018.WANG Tongcheng. Research on hudraulic support automatic system[D]. Qingdao: Shandong University of Science and Technology, 2018. [15] 刘清,韩秀琪,徐兰欣,等. 综采工作面采煤机和液压支架协同控制技术[J]. 工矿自动化,2020,46(5):43-48.LIU Qing,HAN Xiuqi,XU Lanxin,et al. Cooperative control technology of shear and hydraulic support on fully-mechanized coal mining face[J]. Industry and Mine Automation,2020,46(5):43-48. [16] 付翔,王然风,赵阳升. 液压支架群组跟机推进行为的智能决策模型[J]. 煤炭学报,2020,45(6):2065-2077.FU Xiang,WANG Ranfeng,ZHAO Yangsheng. Intelligent decision-making model on the of hydraulic supports group advancing behavior to follow shearer[J]. Journal of China Coal Society,2020,45(6):2065-2077. -

下载:

下载: