Fault diagnosis method of rolling bearing based on MTF and DenseNet

-

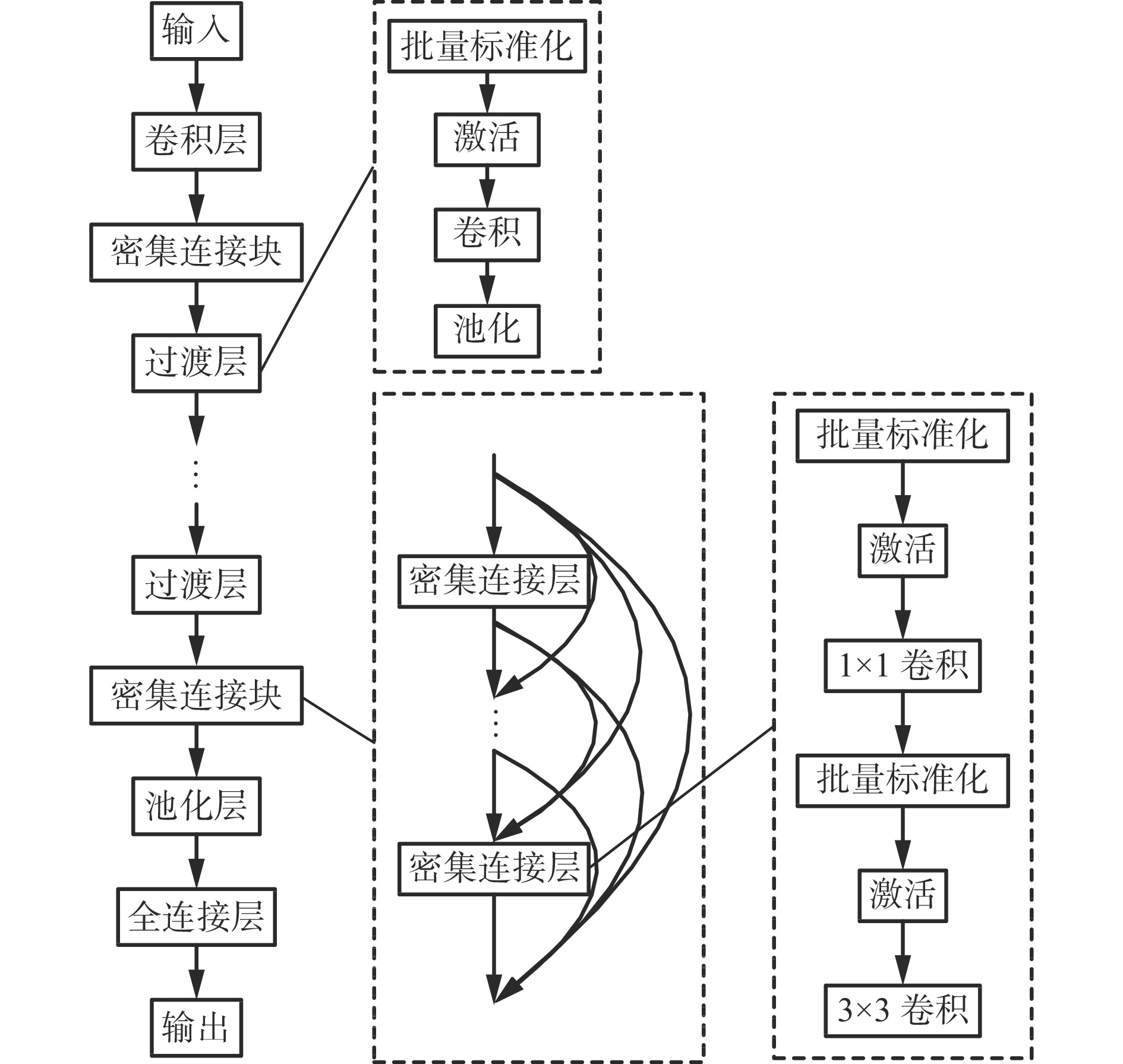

摘要: 基于模型和基于信号处理与分析的滚动轴承故障诊断方法存在建模困难、信号特征难以提取等问题;基于浅层机器学习的滚动轴承故障诊断方法对复杂数据的特征学习能力有限;基于深度学习的滚动轴承故障诊断方法多采用卷积神经网络,但随着网络深度加深会出现梯度弥散或消失的问题,且直接将滚动轴承振动信号转换成一维或二维图像作为网络输入会无法保留信号间的时间相关性,导致信号信息丢失。针对上述问题,提出了一种基于马尔可夫变迁场(MTF)和密集连接卷积网络(DenseNet)的滚动轴承故障诊断方法。将滚动轴承振动信号通过MTF编码后生成二维图像,保留了信号的时序信息和状态迁移信息;将二维图像作为DenseNet的输入,通过DenseNet对滚动轴承振动信号故障特征进行提取,增强了特征信息传播,使特征信息得到充分利用,进而实现故障分类识别。采用凯斯西储大学轴承数据集上的数据进行试验,结果表明,该方法能有效识别滚动轴承故障类型,故障诊断准确率达99.5%。为进一步验证该方法在电动机载荷发生变化情况下的故障诊断能力及优越性,选取灰度图、包络谱图、倒频谱图和MTF生成图4种网络输入图像分别与Inception,ResNet,DenseNet 3种网络相结合的方法进行对比试验,结果表明:不同方法的故障诊断准确率均在电动机载荷不变时高于电动机载荷变化时;MTF+DenseNet方法故障诊断准确率高于其他方法,在电动机载荷发生变化的情况下仍具有较高的故障诊断准确率,平均值为94.53%,泛化性能较好。Abstract: The fault diagnosis methods of rolling bearing based on model and signal processing and analysis have the problems of modeling difficulty and signal characteristic extraction difficulty. The rolling bearing fault diagnosis method based on shallow machine learning has limited capability to learn the characteristics of complex data. The convolutional neural networks are often used in rolling bearing fault diagnosis methods based on deep learning. But with the deepening of the network, gradient dispersion or disappearance will occur. And directly converting the rolling bearing vibration signal into one-dimensional or two-dimensional images as network input will not preserve the time correlation between the signals, resulting in the loss of signal information. To solve these problems, a fault diagnosis method for rolling bearing based on Markov transition field(MTF) and densely connected convolutional networks(DenseNet) is proposed. The vibration signal of the rolling bearing is coded by MTF to generate a two-dimensional image. The time sequence information and the state transition information of the signal are preserved. The two-dimensional image is taken as the input of DenseNet, and the fault characteristics of the rolling bearing vibration signal are extracted through DenseNet. The method enhances the propagation of characteristic information, makes full use of characteristic information, and then realizes fault classification and identification. The data on the Case Western Reserve University bearing dataset is used for the test. The results show that the method can effectively identify the fault types of rolling bearings, and the accuracy of fault diagnosis is 99.5%. In order to further verify the fault diagnosis capability and superiority of this method when the motor load changes, four kinds of network input images, namely, gray-scale image, envelope spectrum image, cepstrum image and MTF generation image, are selected for comparative experiments with the method of combining three networks, namely, Inception, ResNet and DenseNet. The results show that the fault diagnosis accuracy of different methods is higher when the motor load is unchanged than when the motor load is changed. The fault diagnosis accuracy of MTF+DenseNet method is higher than that of other methods. The proposed method still has a high fault diagnosis accuracy when the motor load changes, with an average value of 94.53% and good generalization performance.

-

表 1 试验数据集

Table 1. Experimental dataset

故障尺寸/mm 故障

位置故障标签 数据集A

(载荷0.746 kW)数据集B

(载荷1.491 kW)数据集C

(载荷2.237 kW)训练样本数 测试样本数 训练样本数 测试样本数 训练样本数 测试样本数 0 无 1 400 100 400 100 400 100 0.18 内圈 2 400 100 400 100 400 100 滚动体 3 400 100 400 100 400 100 外圈 4 400 100 400 100 400 100 0.36 内圈 5 400 100 400 100 400 100 滚动体 6 400 100 400 100 400 100 外圈 7 400 100 400 100 400 100 0.54 内圈 8 400 100 400 100 400 100 滚动体 9 400 100 400 100 400 100 外圈 10 400 100 400 100 400 100 表 2 不同方法故障诊断结果对比

Table 2. Comparison of fault diagnosis results of different methods

网络 输入图像 准确率/% A→A A→B A→C B→A B→B B→C C→A C→B C→C 平均 Inception 灰度图 91.7 71.3 67.3 73.6 91.4 77.1 67.5 78.4 90.6 78.77 包络谱图 94.9 78.6 73.5 78.6 93.3 85.4 76.1 86.2 92.6 84.36 倒频谱图 90.3 71.7 70.2 73.7 90.0 85.8 72.3 84.4 92.3 81.19 MTF生成图 98.3 85.1 77.5 82.9 97.3 85.7 83.5 83.2 97.1 87.84 ResNet 灰度图 94.4 76.5 74.1 78.5 93.5 86.1 74.3 82.2 93.3 83.66 包络谱图 94.5 78.0 74.1 81.5 94.8 86.2 72.3 84.6 94.4 84.49 倒频谱图 97.0 84.0 82.9 81.8 94.1 89.4 79.2 92.9 97.0 88.70 MTF生成图 98.8 85.8 80.7 84.7 98.4 90.6 85.3 85.1 98.2 89.73 DenseNet 灰度图 96.8 76.5 74.1 79.5 95.7 82.5 84.0 82.0 96.4 85.28 包络谱图 97.3 83.7 76.3 86.4 98.1 81.3 73.2 87.2 97.6 86.79 倒频谱图 98.8 86.9 85.6 87.0 98.4 96.1 83.0 94.8 97.6 92.02 MTF生成图 99.6 92.6 84.9 92.3 99.5 96.9 92.1 93.3 99.6 94.53 -

[1] 徐青青,赵海芳,李守军. 一种煤矿机械轴承故障诊断方法[J]. 工矿自动化,2019,45(10):80-85,90.XU Qingqing,ZHAO Haifang,LI Shoujun. A fault diagnosis method for coal mine machinery bearing[J]. Industry and Mine Automation,2019,45(10):80-85,90. [2] 樊红卫,张旭辉,曹现刚,等. 智慧矿山背景下我国煤矿机械故障诊断研究现状与展望[J]. 振动与冲击,2020,39(24):194-204. doi: 10.13465/j.cnki.jvs.2020.24.027FAN Hongwei,ZHANG Xuhui,CAO Xiangang,et al. Research status and prospect of fault diagnosis of China's coal mine machines under background of intelligent mine[J]. Journal of Vibration and Shock,2020,39(24):194-204. doi: 10.13465/j.cnki.jvs.2020.24.027 [3] 文红权. 基于深度信念网络的故障诊断研究[D]. 北京: 北京交通大学, 2018.WEN Hongquan. A fault diagnosis method based on deep belief networks[D]. Beijing: Beijing Jiaotong University, 2018. [4] 裴杏龙. 基于信号处理与深度学习的滚动轴承故障诊断方法研究[D]. 重庆: 重庆理工大学, 2022.PEI Xinglong. Research on fault diagnosis of rolling bearing based on signal processing and deeping learning[D]. Chongqing: Chongqing University of Technology, 2022. [5] 李伟龙. 基于深度学习的滚动轴承故障诊断的方法研究[D]. 哈尔滨: 哈尔滨理工大学, 2022.LI Weilong. Research on rolling bearing fault diagnosis method based on deep learning[D]. Harbin: Harbin University of Science and Technology, 2022. [6] 江俊君,李震宇,刘贤明. 基于深度学习的单目深度估计方法综述[J]. 计算机学报,2022,45(6):1276-1307. doi: 10.11897/SP.J.1016.2022.01276JIANG Junjun,LI Zhenyu,LIU Xianming. Deep learning based monocular depth estimation:a survey[J]. Chinese Journal of Computers,2022,45(6):1276-1307. doi: 10.11897/SP.J.1016.2022.01276 [7] 张伟. 基于卷积神经网络的轴承故障诊断算法研究[D]. 哈尔滨: 哈尔滨工业大学, 2017.ZHANG Wei. Study on bearing fault diagnosis algorithm based on convolutional neural network[D]. Harbin: Harbin Institute of Technology, 2017. [8] 陈晓雷,孙永峰,李策,等. 基于卷积神经网络和双向长短期记忆的稳定抗噪声滚动轴承故障诊断[J]. 吉林大学学报(工学版),2022,52(2):296-309.CHEN Xiaolei,SUN Yongfeng,LI Ce,et al. Stable anti-noise fault diagnosis of rolling bearing based on CNN-BiLSTM[J]. Journal of Jilin University(Engineering and Technology Edition),2022,52(2):296-309. [9] 赵小强,张亚洲. 利用改进卷积神经网络的滚动轴承变工况故障诊断方法[J]. 西安交通大学学报,2021,55(12):108-118.ZHAO Xiaoqiang,ZHANG Yazhou. Improved CNN-based fault diagnosis method for rolling bearings under variable working conditions[J]. Journal of Xi'an Jiaotong University,2021,55(12):108-118. [10] 宫文峰,陈辉,张泽辉,等. 基于改进卷积神经网络的滚动轴承智能故障诊断研究[J]. 振动工程学报,2020,33(2):400-413. doi: 10.16385/j.cnki.issn.1004-4523.2020.02.021GONG Wenfeng,CHEN Hui,ZHANG Zehui,et al. Intelligent fault diagnosis for rolling bearing based on improved convolutional neural network[J]. Journal of Vibration Engineering,2020,33(2):400-413. doi: 10.16385/j.cnki.issn.1004-4523.2020.02.021 [11] 姜家国,郭曼利,杨思国. 基于GAF和DenseNet的滚动轴承故障诊断方法[J]. 工矿自动化,2021,47(8):84-89.JIANG Jiaguo,GUO Manli,YANG Siguo. Fault diagnosis of rolling bearings based on GAF and DenseNet[J]. Industry and Mine Automation,2021,47(8):84-89. [12] HUANG Gao, LIU Zhuang, LAURENS V, et al. Densely connected convolutional networks[C]. IEEE Conference on Computer Vision and Pattern Recognition, Honolulu, 2017: 2261-2269. [13] 雷春丽,夏奔锋,薛林林,等. 基于MTF−CNN的滚动轴承故障诊断方法[J]. 振动与冲击,2022,41(9):151-158. doi: 10.13465/j.cnki.jvs.2022.09.020LEI Chunli,XIA Benfeng,XUE Linlin,et al. Rolling bearing fault diagnosis method based on MTF-CNN[J]. Journal of Vibration and Shock,2022,41(9):151-158. doi: 10.13465/j.cnki.jvs.2022.09.020 [14] 曹洁,马佳林,黄黛麟,等. 一种基于多通道马尔可夫变迁场的故障诊断方法[J]. 吉林大学学报(工学版),2022,52(2):491-496.CAO Jie,MA Jialin,HUANG Dailin,et al. A fault diagnosis method based on multi Markov transition field[J]. Journal of Jilin University(Engineering and Technology Edition),2022,52(2):491-496. [15] 王小玉,韩彤彤,尚学达. 基于密集连接网络的驾驶疲劳状态检测方法[J]. 北京邮电大学学报,2021,44(1):52-58.WANG Xiaoyu,HAN Tongtong,SHANG Xueda. Driving fatigue state detecting method based on densely connected convolutional network[J]. Journal of Beijing University of Posts and Telecommunications,2021,44(1):52-58. [16] 熊鹏,汤宝平,邓蕾,等. 基于动态加权密集连接卷积网络的变转速行星齿轮箱故障诊断[J]. 机械工程学报,2019,55(7):52-57. doi: 10.3901/JME.2019.07.052XIONG Peng,TANG Baoping,DENG Lei,et al. Fault diagnosis for planetary gearbox by dynamically weighted densely connected convolutional networks[J]. Journal of Mechanical Engineering,2019,55(7):52-57. doi: 10.3901/JME.2019.07.052 [17] 曹思灿. 基于生成对抗网络的轴承故障诊断方法研究[D]. 武汉: 华中科技大学, 2019.CAO Sican. Generative adversarial network based methods for rolling bearing fault diagnosis[D]. Wuhan: Huazhong University of Science and Technology, 2019. -

下载:

下载: