Health condition assessment of centrifugal pump based on AHP-TOPSIS comprehensive evaluation method

-

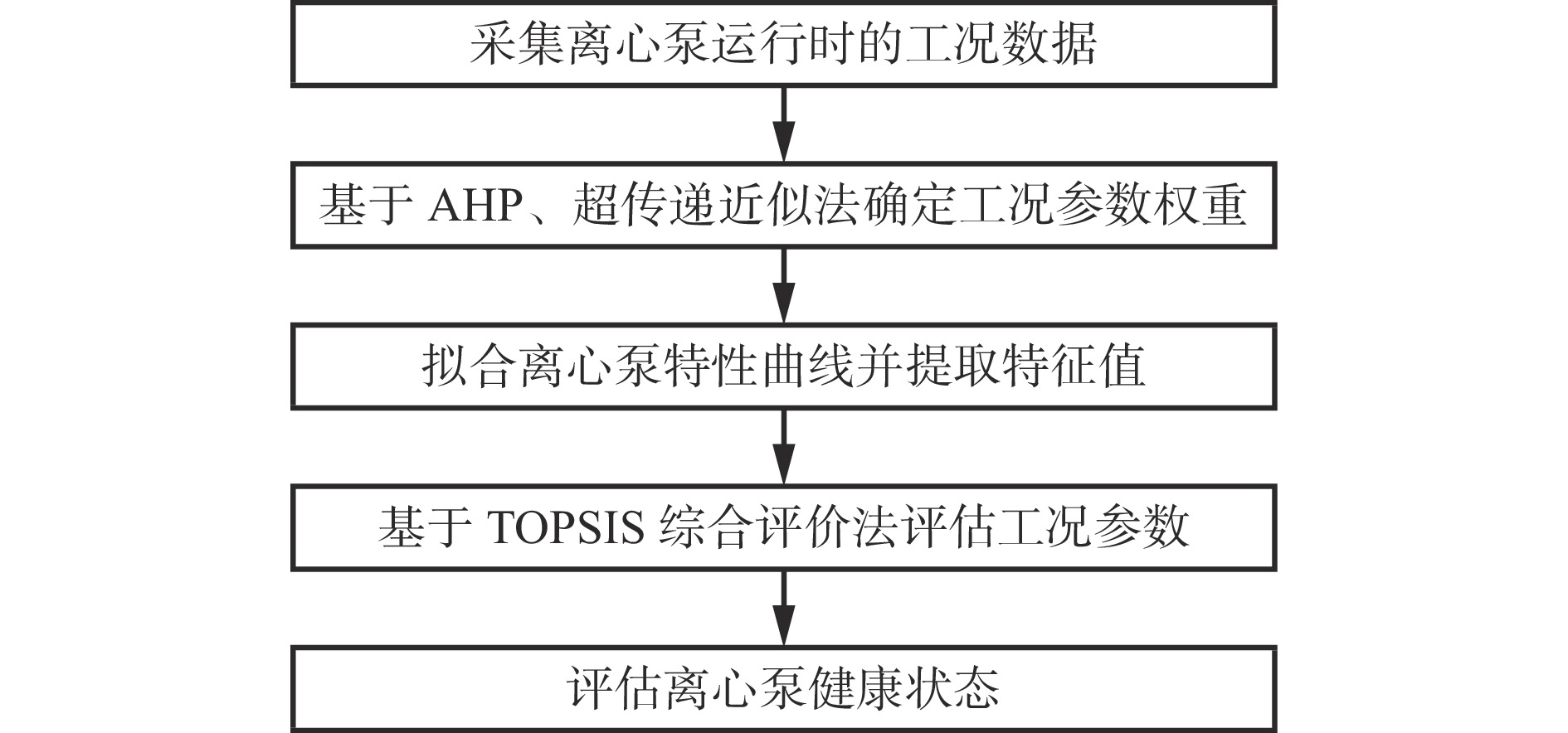

摘要: 针对离心泵叶轮磨损问题,现有研究大都集中在对叶轮磨损的数值仿真分析、振动信号分析和磨损量检测上,很少对叶轮磨损下的离心泵工况参数进行研究。针对该问题 ,提出了一种基于层次分析法 (AHP)和优劣解距离法(TOPSIS)综合评价的离心泵健康状态评估方法。首先根据离心泵的运行条件,结合离心泵的性能要求,确定了表征离心泵健康状态的工况参数(流量、扬程、效率、轴功率);然后以叶轮外径和比转数大小作为工况参数评价指标,利用AHP和超传递近似法确定各工况参数对离心泵健康状态的权重值;最后利用TOPSIS综合评价法评估离心泵工况参数,通过加权求和方式得到离心泵的健康状态评分,实现对离心泵的健康状态评估。以IS−100−80−125型单级离心泵为研究对象,将叶轮外径由125 mm磨损至87 mm,得到离心泵不同叶轮外径下的工况参数,利用AHP−TOPSIS综合评价法评估离心泵各工况参数和健康状态,结果表明:离心泵的叶轮磨损量和离心泵健康状态呈线性关系,随着叶轮磨损量的不断增加,离心泵排水能力不断降低,评估结果符合离心泵实际情况,证明了该方法的合理性和可行性。Abstract: In view of the problem of centrifugal pump impeller wear, the existing research mostly concentrates on numerical simulation analysis, vibration signal analysis and wear detection of impeller wear. There are few studies on the working condition parameters of centrifugal pump under impeller wear. In order to solve this problem, a health condition assessment method of centrifugal pump based on analytic hierarchy process (AHP) and technique for order preference by similarity to ideal solution (TOPSIS) is proposed. Firstly, according to the operating conditions of centrifugal pump and the performance requirements of centrifugal pump, the operating parameters (flow, head, efficiency and shaft power) characterizing the health condition of centrifugal pump are determined. Secondly, the outer diameter and the specific speed of the impeller are taken as the evaluation indexes of the working condition parameters. The weight values of each working condition parameter to the health condition of the centrifugal pump are determined by using the AHP and the super-transitive approximate method. Finally, the working condition parameters of the centrifugal pump are evaluated by TOPSIS comprehensive evaluation method. The health condition score of the centrifugal pump is obtained by weighted summation, to realize the health condition evaluation of the centrifugal pump. Taking the IS-100-80-125 single-stage centrifugal pump as the research object, the outer diameter of the impeller is worn from 125 mm to 87 mm, and the working parameters of the centrifugal pump with different outer diameters of the impeller are obtained. The working parameters and the health condition of the centrifugal pump are evaluated by the AHP-TOPSIS comprehensive evaluation method. The results show that there is a linear relationship between impeller wear and centrifugal pump health. With the increasing wear of impeller, the drainage capacity of centrifugal pump decreases. The evaluation results are in line with the actual situation of the centrifugal pump, which proves the rationality and feasibility of this method.

-

表 1 判断矩阵构建原则

Table 1. Construction principle of judgment matrix

程度 含义 1 2个因素相比同等重要 3 2个因素相比前者比后者稍微重要 5 2个因素相比前者比后者明显重要 7 2个因素相比前者比后者强烈重要 9 2个因素相比前者比后者极端重要 2,4,6,8 上述两相邻判断的中值 倒数 因素i与j比较的结果为aij,则因素j与i比较的结果为aji = 1 / aij 表 2 平均随机一致性指标取值

Table 2. Average random consistency index values

s 1 2 3 4 5 6 7 Ir 0 0 0.58 0.89 1.12 1.24 1.32 表 3 离心泵健康状态评估指标体系

Table 3. The health condition evaluation index system of centrifugal pump

工况参数 特征值 $ Q $ $ 0.6Q' $ $ 0.8Q' $ $ Q' $ $ 1.2Q' $ $ H $ $ {h_1} $ $ {h_2} $ $ {h_3} $ $ {h_4} $ $ \eta $ $ {e_1} $ $ {e_2} $ $ {e_3} $ $ {e_4} $ $ P $ $ {p_1} $ $ {p_2} $ $ {p_3} $ $ {p_4} $ 表 4 不同指标下的判断矩阵

Table 4. The judgment matrix under different indexes

准则层 判断

矩阵工况

参数两两相比重要性 Q H η P 叶轮外径

(管道)A1 Q 1 1/2 7 1/3 H 2 1 8 1/2 η 1/7 1/8 1 1/9 P 3 2 9 1 叶轮外径

(流量)A2 Q 1 1/2 7 1/3 H 7 1 9 2 η 1/2 1/9 1 1/8 P 5 1/2 8 1 比转数 A3 Q 1 2 9 3 H 1/2 1 7 2 η 1/9 1/7 1 1/5 P 1/3 1/2 5 1 表 5 一致性比率值

Table 5. Consistent ratio values

判断矩阵 A1 A2 A3 Rc 0.0346 0.0166 0.0157 表 6 工况参数特征值权重

Table 6. The weight of characteristic values of working condition parameters

工况参数 权重 Q 0.0725 0.1697 0.4723 0.2854 H 0.1405 0.0518 0.0675 0.7402 η 0.0664 0.2475 0.6861 0 P 0.0550 0.1217 0.2568 0.5665 表 7 最优、最劣状态特征值正向化和归一化结果

Table 7. Normalization and normalization results of characteristic values of the optimal and worst conditions

特征值 工况参数 特征值正向化和归一化结果 最优特征值 Q 1 1 1 1 H 1 1 1 1 η 1 1 1 0 P 1 1 1 1 最劣特征值 Q 0.3 0 0 0 H 0 1 0 0 η 0 0 0 0 P 0 0 0 0 -

[1] 国家煤矿安全监察局. 国家煤矿安全监察局关于印发《煤矿防治水细则》的通知(煤安监调查〔2018〕14号)[EB/OL]. (2018-06-06)[2022-05-23]. http://www.gov.cn/zhengce/zhengceku/2018-12/31/content_5448431.htm.National Coal Mine Safety Administration. Notice of the National Coal Mine Safety Administration on the Issuance of Rules for the Prevention and Control of Water in Coal Mines (Coal Safety Supervision Investigation [2018] No.14) [EB/OL]. (2018-06-06) [2022-05-23]. http//www.gov.cn/zhengce/zhengceku/2018-12/31/content_5448431.htm. [2] 张胜,曹骞,康灿,等. 固体颗粒粒径对输送泵叶轮磨损特性的影响[J]. 矿冶工程,2021,41(4):19-23. doi: 10.3969/j.issn.0253-6099.2021.04.005ZHANG Sheng,CAO Qian,KANG Can,et al. Influence of solid particle size on wear behavior of the impeller of delivery pump[J]. Mining and Metallurgical Engineering,2021,41(4):19-23. doi: 10.3969/j.issn.0253-6099.2021.04.005 [3] 王勇,李刚祥,袁霄,等. 混合沙粒对半开式叶轮离心泵磨损的影响[J]. 排灌机械工程学报,2021,39(8):764-769.WANG Yong,LI Gangxiang,YUAN Xiao,et al. Influence of mixed sand on wear of centrifugal pump with semi-open impeller[J]. Journal of Drainage and Irrigation Machinery Engineering,2021,39(8):764-769. [4] 赖芬,王凤鸣,朱相源,等. 基于E/CRC磨损模型的离心泵壁面磨损特性研究[J]. 哈尔滨工程大学学报,2021,42(5):719-728.LAI Fen,WANG Fengming,ZHU Xiangyuan,et al. Erosion characteristics of centrifugal pumps based on E/CRC erosion model[J]. Journal of Harbin Engineering University,2021,42(5):719-728. [5] 郭文琪,田慕琴,宋建成,等. 基于多源信号融合的离心泵叶轮磨损故障分析[J]. 工矿自动化,2018,44(6):74-79. doi: 10.13272/j.issn.1671-251x.2018020029GUO Wenqi,TIAN Muqin,SONG Jiancheng,et al. Wear fault analysis of centrifugal pump impeller based on multi-source signal fusion[J]. Industry and Mine Automation,2018,44(6):74-79. doi: 10.13272/j.issn.1671-251x.2018020029 [6] 尹江南,袁寿其,骆寅,等. 离心泵叶轮不同磨损程度下的振动信号分析[J]. 排灌机械工程学报,2020,38(2):139-144.YIN Jiangnan,YUAN Shouqi,LUO Yin,et al. Analysis of vibration signal characteristics of centrifugal pump impeller under different wear degrees[J]. Journal of Drainage and Irrigation Machinery Engineering,2020,38(2):139-144. [7] BOHN B,KHOIE R,GOPALUNI R B,et al. Development and characterization of a non-intrusive sensor to measure wear in centrifugal pumps[J]. IEEE Sensors Journal,2019,19(18):7906-7914. doi: 10.1109/JSEN.2019.2919283 [8] 段礼祥,张来斌,钱永梅. AHP−模糊综合评价法在离心泵安全评价中的应用[J]. 中国安全生产科学技术,2011,7(2):127-131.DUAN Lixiang,ZHANG Laibin,QIAN Yongmei. Application of fuzzy comprehensive evaluation in safety assessment of centrifuge pumps[J]. Journal of Safety Science and Technology,2011,7(2):127-131. [9] 黄德才,李秉焱. AHP中群决策的几何平均超传递近似法[J]. 控制与决策,2012,27(5):797-800. doi: 10.13195/j.cd.2012.05.160.huangdc.010HUANG Decai,LI Bingyan. Geometric mean and super-transitive approximate method of AHP group decision[J]. Control and Decision,2012,27(5):797-800. doi: 10.13195/j.cd.2012.05.160.huangdc.010 [10] 付志扬,王涛,孔令号,等. 基于AHP−TOPSIS算法的重要电力客户用电状态评估[J]. 电网技术,2022,22(9):1554-1559. doi: 10.13335/j.1000-3673.pst.2021.2280FU Zhiyang,WANG Tao,KONG Linghao,et al. Power consumption state evaluation of important power customers based on AHP-TOPSIS algorithm[J]. Power System Technology,2022,22(9):1554-1559. doi: 10.13335/j.1000-3673.pst.2021.2280 [11] GBT 25411—2010 IB型单级离心泵 [S].GBT 25411—2010 IB Single stage centrifugal pump [S]. [12] 郭文琪. 基于物联网的矿井主排水设备状态监测及寿命管理系统的开发[D]. 太原: 太原理工大学, 2018.GUO Wenqi. Development of IoT based monitoring and life management system for drainage equipment in mine[D]. Taiyuan: Taiyuan University of Technology, 2018. [13] 王凯,刘厚林,袁寿其,等. 离心泵多工况水力性能优化设计方法[J]. 排灌机械工程学报,2012,30(1):20-24. doi: 10.3969/j.issn.1674-8530.2012.01.005WANG Kai,LIU Houlin,YUAN Shouqi,et al. Optimization method for hydraulic performance of centrifugal pump at multi-operation points[J]. Journal of Drainage and Irrigation Machinery Engineering,2012,30(1):20-24. doi: 10.3969/j.issn.1674-8530.2012.01.005 [14] 童水光,赵航,刘会琴,等. 中开多级离心泵效率优化计算方法[J]. 浙江大学学报(工学版),2019,53(5):988-996,1005.TONG Shuiguang,ZHAO Hang,LIU Huiqin,et al. Optimization calculation method for efficiency of multistage split case centrifugal pump[J]. Journal of Zhejiang University (Engineering Science),2019,53(5):988-996,1005. [15] 关醒凡. 现代泵理论与设计[M]. 北京: 中国宇航出版社, 2011.GUAN Xingfan. Modern pump theory and design[M]. Beijing: China Aerospace Press, 2011. -

下载:

下载: