Pressure relief law and application of deep-buried high-stress bedding coal by hydraulic flushing

-

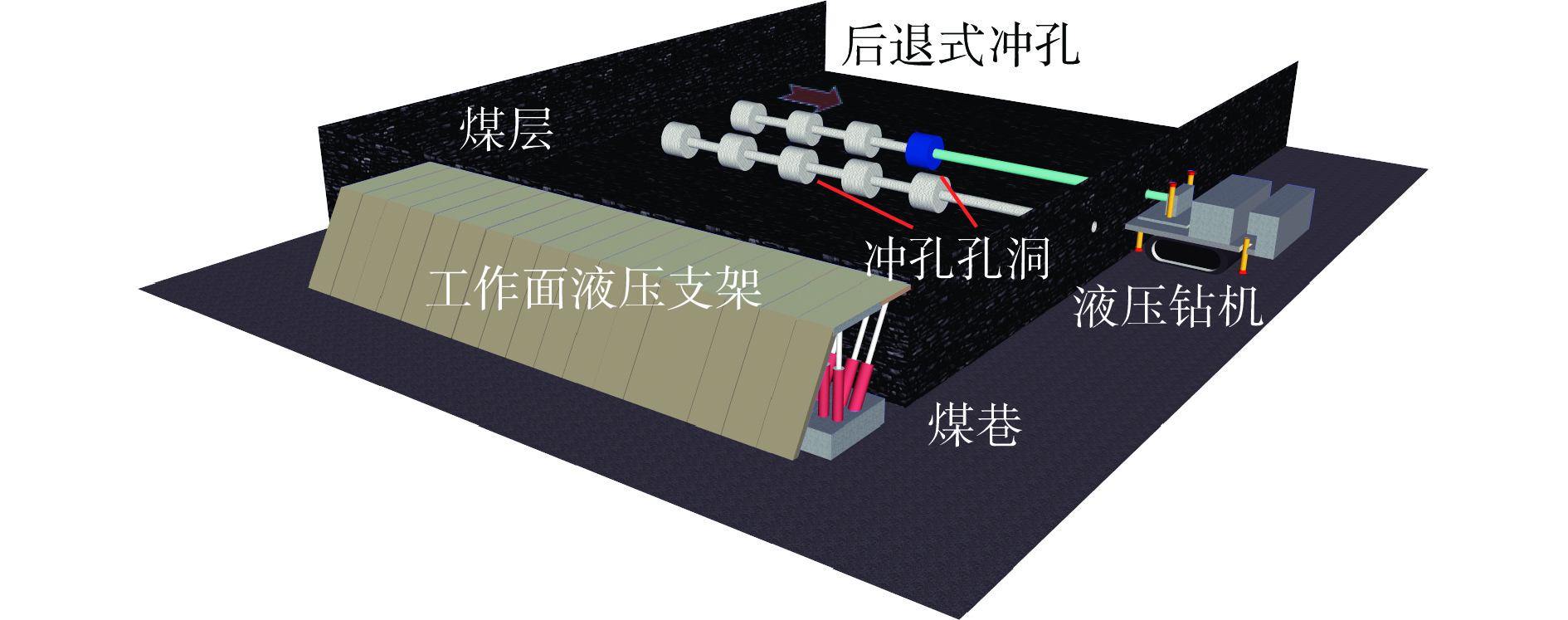

摘要: 为解决煤矿深部开采工作面煤与瓦斯突出危险性高的问题,以首山一矿12090工作面为工程背景,采用数值模拟方法分析了深埋藏高应力环境下采煤工作面顺层水力冲孔后的煤体变形和应力变化规律,得出结论:水力冲孔孔洞周围煤体朝向孔洞变形,有利于煤体内的裂隙发育和导通,进而提高煤体渗透率;冲孔区域煤体的水平应力有效降低,各冲孔孔洞形成的卸压区域相互连通,形成卸压条带,有利于瓦斯运移与抽采。依据数值模拟结果并结合实际工程,确定了首山一矿12090工作面水力冲孔工程方案:上帮钻孔角度为5~6°,下帮钻孔角度为−5~−4°;钻孔间距为4 m,每个冲孔孔洞长度为1 m,每个钻孔的冲孔孔洞间距为7 m,距巷帮30 m范围内不进行冲孔作业;冲孔水压为5~6 MPa,流量为120~160 L/min。实践表明:采用该方案后,每月成孔数达40个,成孔率达80%;冲孔钻孔瓦斯抽采浓度高、衰减慢,抽采50 d后冲孔钻孔内瓦斯体积分数为40%~60%,为普通钻孔的2~3倍,抽采120 d后冲孔钻孔内瓦斯体积分数仍有20%,水力冲孔有效提高了瓦斯抽采效果,降低了煤层瓦斯含量;回风流平均瓦斯体积分数降至0.5%以下;工作面平均日进尺由2.4 m增加至3.2 m,提高了生产率。Abstract: In order to solve the problem of the high risk of coal and gas outburst in deep coal working face, taking 12090 working face of Shoushan No.1 Coal Mine as the engineering background, the paper analyzes the deformation and stress variation law of coal body after hydraulic flushing in coal working face under deep-buried and high-stress environment by numerical simulation method. The conclusions are listed as follows. The coal body around the hydraulic flushing hole deforms towards the hole, which is conducive to the development and conduction of cracks in the coal body, thus improving the permeability of the coal body. The horizontal stress of the coal body in the flushing area is effectively reduced. The pressure relief areas formed by each punching hole are interconnected to form a pressure relief strip, which is conducive to gas migration and extraction. According to the numerical simulation results and the actual project, the hydraulic flushing project scheme of 12090 working face in Shoushan No. 1 Coal Mine is determined. The upper side drilling angle is 5-6°, and the lower side drilling angle is −5-−4°. The drilling spacing is 4 m, and the length of each punching hole is 1 m. The spacing of flushing holes in each borehole is 7 m, and no flushing operation is carried out within 30 m from the roadway side. The flushing water pressure is 5-6 MPa, and the flow rate is 120-160 L/min. The practice shows that after adopting this scheme, the number of holes completed per month reaches 40 and the completion rate reaches 80%. The gas extraction concentration in the flushing hole is high and the gas attenuation is slow. After 50 days of extraction, the gas volume fraction in the flushing hole is 40%-60%, which is 2-3 times of that in the ordinary hole. After 120 days of extraction, the gas volume fraction in the flushing hole is still 20%. Hydraulic flushing effectively improves the gas extraction effect and reduces the gas content in coal seams. The average gas volume fraction of return air flow decreases to below 0.5%. The average daily footage of the working face increases from 2.4 m to 3.2 m, which improves productivity.

-

表 1 数值模型物理力学参数

Table 1. Mechanical mechanics parameters of numerical model

岩层 体积模

量/GPa剪切模

量/GPa黏聚力/

MPa抗拉强

度/MPa内摩擦

角/(°)密度/

(kg·m−3)顶板/

底板12 9 5 3 33 2500 煤层 3.26 1.28 0.57 0.33 48 1438 -

[1] 马文涛,马小辉,吕大钊,等. 深部掘进巷道爆破卸压防治冲击地压技术[J]. 工矿自动化,2022,48(1):119-124.MA Wentao,MA Xiaohui,LYU Dazhao,et al. Blasting pressure relief technology for preventing rock burst in deep heading roadway[J]. Industry and Mine Automation,2022,48(1):119-124. [2] FAN Deyang,LIU Xuesheng,TAN Yunliang,et al. Roof cutting parameters design for gob-side entry in deep coal mine:a case study[J]. Energies,2019,12(10):2032. doi: 10.3390/en12102032 [3] 崔建军. 深部沿空掘巷变形破坏机理及控制技术研究[J]. 煤炭科学技术,2017,45(7):12-17. doi: 10.13199/j.cnki.cst.2017.07.003CUI Jianjun. Study on deformation and failure mechanism and control technology of deeply gob-side entry driving[J]. Coal Science and Technology,2017,45(7):12-17. doi: 10.13199/j.cnki.cst.2017.07.003 [4] 杨天鸿,徐涛,刘建新,等. 应力−损伤−渗流耦合模型及在深部煤层瓦斯卸压实践中的应用[J]. 岩石力学与工程学报,2005,24(16):2900-2905. doi: 10.3321/j.issn:1000-6915.2005.16.015YANG Tianhong,XU Tao,LIU Jianxin,et al. Coupling model of stess-damage-flow and its application to the investigation of instantaneous seepage mechanism for gas during unloading in coal seam with depth[J]. Chinese Journal of Rock Mechanics and Engineering,2005,24(16):2900-2905. doi: 10.3321/j.issn:1000-6915.2005.16.015 [5] 翟成,徐吉钊. 液氮循环致裂技术强化煤层气抽采的研究与应用展望[J]. 工矿自动化,2020,46(10):1-8. doi: 10.13272/j.issn.1671-251x.17669ZHAI Cheng,XU Jizhao. Research on cyclic liquid nitrogen fracturing technology for enhancing coalbed methane drainage and its application prospect[J]. Industry and Mine Automation,2020,46(10):1-8. doi: 10.13272/j.issn.1671-251x.17669 [6] 刘明举,孔留安,郝富昌,等. 水力冲孔技术在严重突出煤层中的应用[J]. 煤炭学报,2005,30(4):451-454. doi: 10.3321/j.issn:0253-9993.2005.04.010LIU Mingju,KONG Liu'an,HAO Fuchang,et al. Application of hydraulic flushing technology in severe outburst coal[J]. Journal of China Coal Society,2005,30(4):451-454. doi: 10.3321/j.issn:0253-9993.2005.04.010 [7] ZHANG Hao,CHENG Yuanping,YUAN Liang,et al. Hydraulic flushing in soft coal sublayer:gas extraction enhancement mechanism and field application[J]. Energy Science and Technology,2019,7:1970-1993. [8] 潘一山. 煤与瓦斯突出、冲击地压复合动力灾害一体化研究[J]. 煤炭学报,2016,41(1):105-112. doi: 10.13225/j.cnki.jccs.2015.9034PAN Yishan. Integrated study on compound dynamic disaster of coal-gas outburst and rockburst[J]. Journal of China Coal Society,2016,41(1):105-112. doi: 10.13225/j.cnki.jccs.2015.9034 [9] 张嘉凡,程树范,高壮,等. 煤岩液态二氧化碳爆破开采实践与模拟[J]. 煤炭科学技术,2020,48(增刊1):24-27.ZHANG Jiafan,CHENG Shufan,GAO Zhuang,et al. Practice and simulation of coal-rock mining by liquid carbon dioxide blasting[J]. Coal Science and Technology,2020,48(S1):24-27. [10] XU Jizhao,ZHAI Cheng. Petrological and ultrasonic velocity changes of coals caused by thermal cycling of liquid carbon dioxide in coalbed methane recovery[J]. Fuel,2019,249:15-26. doi: 10.1016/j.fuel.2019.03.089 [11] 姚俊辉,陈辉,管伟明,等. 微波加热对煤层顶板砂岩微结构的影响[J]. 煤矿安全,2022,53(2):80-85,92.YAO Junhui,CHEN Hui,GUAN Weiming,et al. Effect of microwave heating on microstructure of sandstone in coal seam roof[J]. Safety in Coal Mines,2022,53(2):80-85,92. [12] 李雁,李兵,姚帅,等. 基于CT扫描的受载破裂煤样注浆封堵效应量化研究[J]. 工矿自动化,2022,48(4):53-59.LI Yan,LI Bing,YAO Shuai,et al. Quantitative study on grouting plugging effect of loaded fractured coal sample based on CT scanning[J]. Journal of Mine Automation,2022,48(4):53-59. [13] 鲍先凯,武晋文,杨东伟,等. 高压电脉冲水压致裂煤体效果试验研究[J]. 煤炭科学技术,2017,45(9):133-138. doi: 10.13199/j.cnki.cst.2017.09.022BAO Xiankai,WU Jinwen,YANG Dongwei,et al. Experimental study on coal fracturing effect by high-voltage pulsed water pressure[J]. Coal Science and Technology,2017,45(9):133-138. doi: 10.13199/j.cnki.cst.2017.09.022 [14] 张登峰,崔永君,李松庚,等. 甲烷及二氧化碳在不同煤阶煤内部的吸附扩散行为[J]. 煤炭学报,2011,36(10):1693-1698. doi: 10.13225/j.cnki.jccs.2011.10.001ZHANG Dengfeng,CUI Yongjun,LI Songgeng,et al. Adsorption and diffusion behaviors of methane and carbon dioxide on various rank coals[J]. Journal of China Coal Society,2011,36(10):1693-1698. doi: 10.13225/j.cnki.jccs.2011.10.001 [15] 梁卫国,吴迪,赵阳升. CO2驱替煤层CH4试验研究[J]. 岩石力学与工程学报,2010,29(4):665-673.LIANG Weiguo,WU Di,ZHAO Yangsheng. Experimental study of coalbeds methane replacement by carbon dioxide[J]. Chinese Journal of Rock Mechanics and Engineering,2010,29(4):665-673. [16] 张苗,邹明俊,吕乐乐,等. 水力压裂过程中陶粒支撑剂运移规律及粒级配比优化[J]. 煤矿安全,2022,53(2):16-19,26.ZHANG Miao,ZOU Mingjun,LYU Lele,et al. Migration law of ceramsite proppant and its granularity matching during coalbed methane fracturing[J]. Safety in Coal Mines,2022,53(2):16-19,26. [17] XU Jizhao,ZHAI Cheng,QIN Lei. Mechanism and application of pulse hydraulic fracturing in improving drainage of coalbed methane[J]. Journal of Natural Gas Science and Engineering,2017,40:79-90. doi: 10.1016/j.jngse.2017.02.012 [18] ZHANG Rong, CHENG Yuanping, YUAN Liang, et al. Enhancement of gas drainage efficiency in a special thick coal seam through hydraulic flushing[J/OL]. [2022-06-20]. https://doi.org/10.1016/j.ijrmms.2019.104085. [19] 刘明举,郭献林,李波,等. 底板巷穿层钻孔水力冲孔防突技术[J]. 煤炭科学技术,2011,39(2):33-35,50. doi: 10.13199/j.cst.2011.02.38.liumj.018LIU Mingju,GUO Xianlin,LI Bo,et al. Outburst prevention technology with borehole hydraulic jet through strata in floor gateway[J]. Coal Science and Technology,2011,39(2):33-35,50. doi: 10.13199/j.cst.2011.02.38.liumj.018 -

下载:

下载: