Research on radiation performance and safety performance of X-ray source for mine transmission detection

-

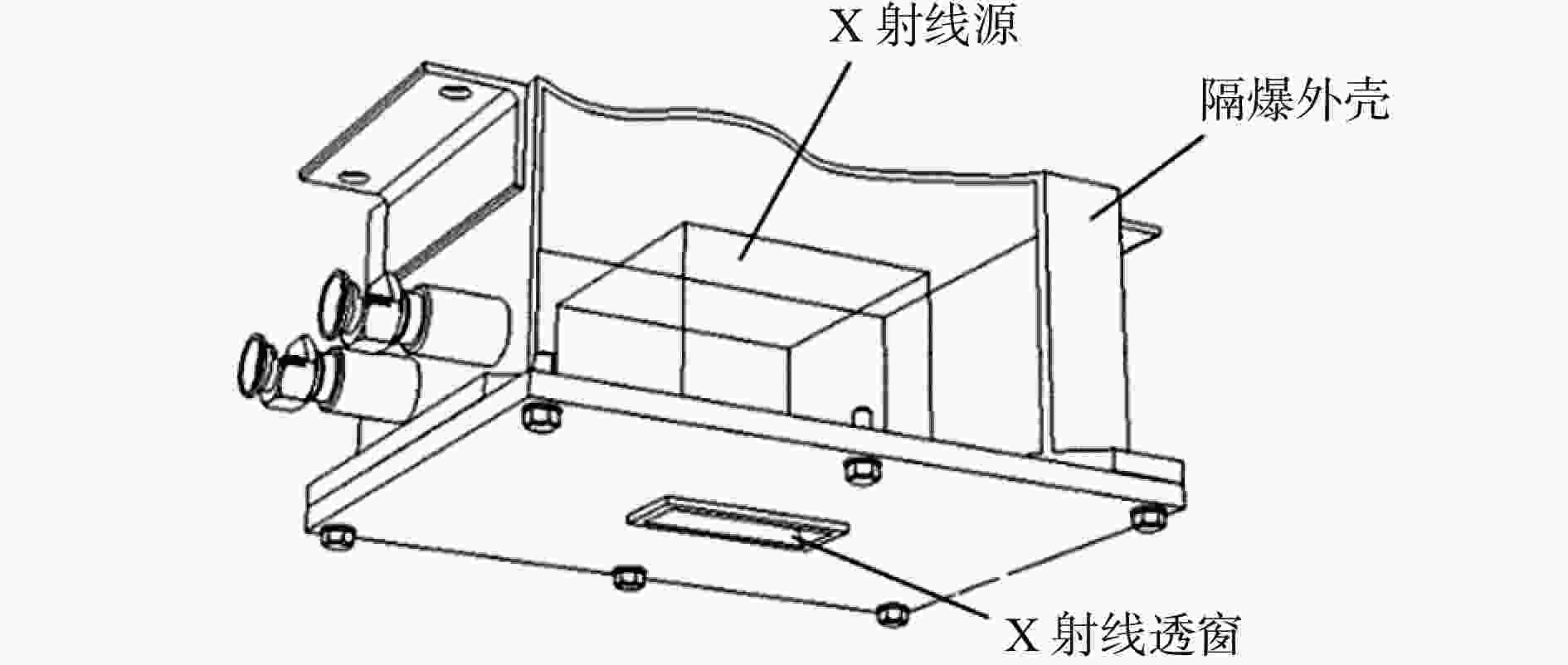

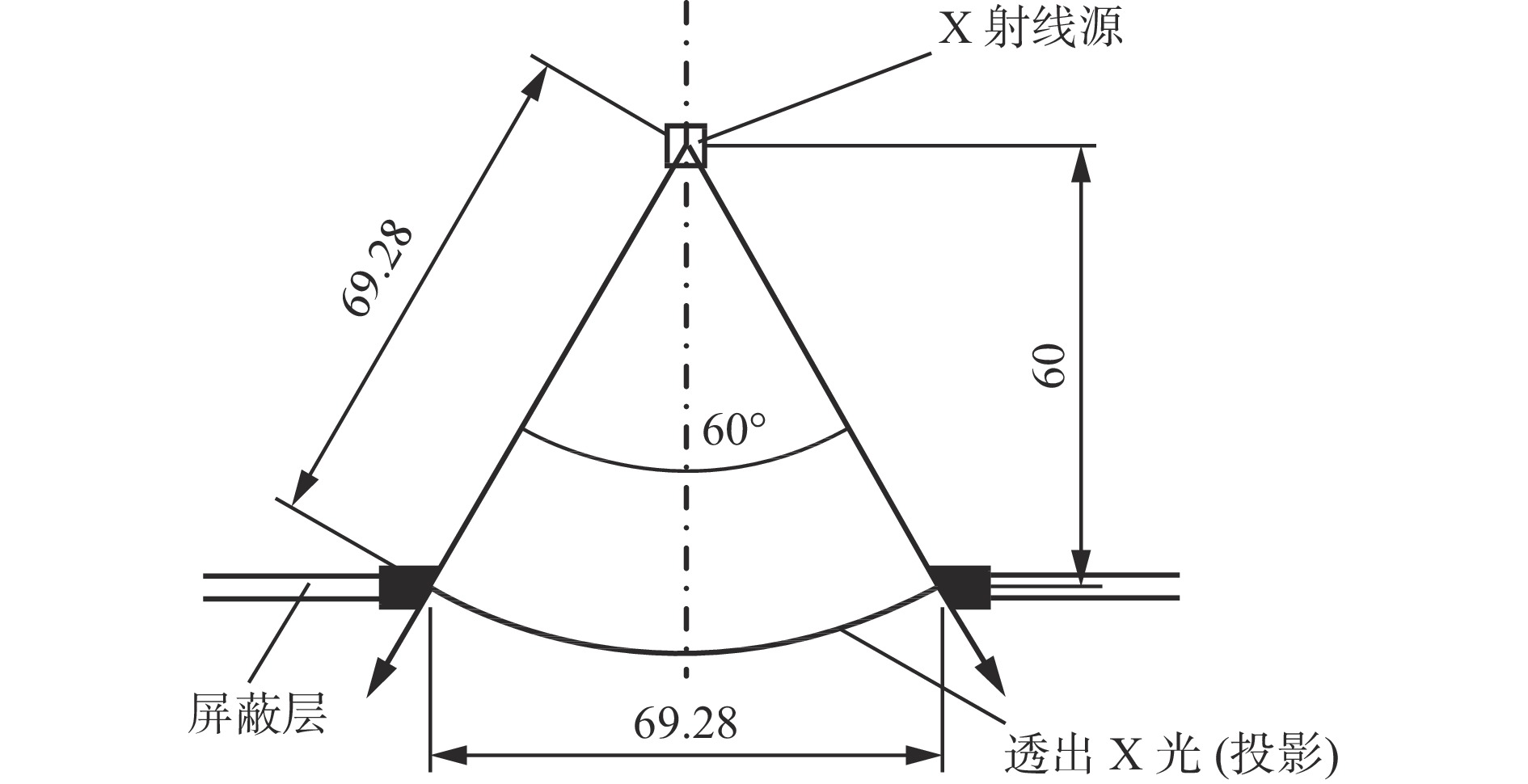

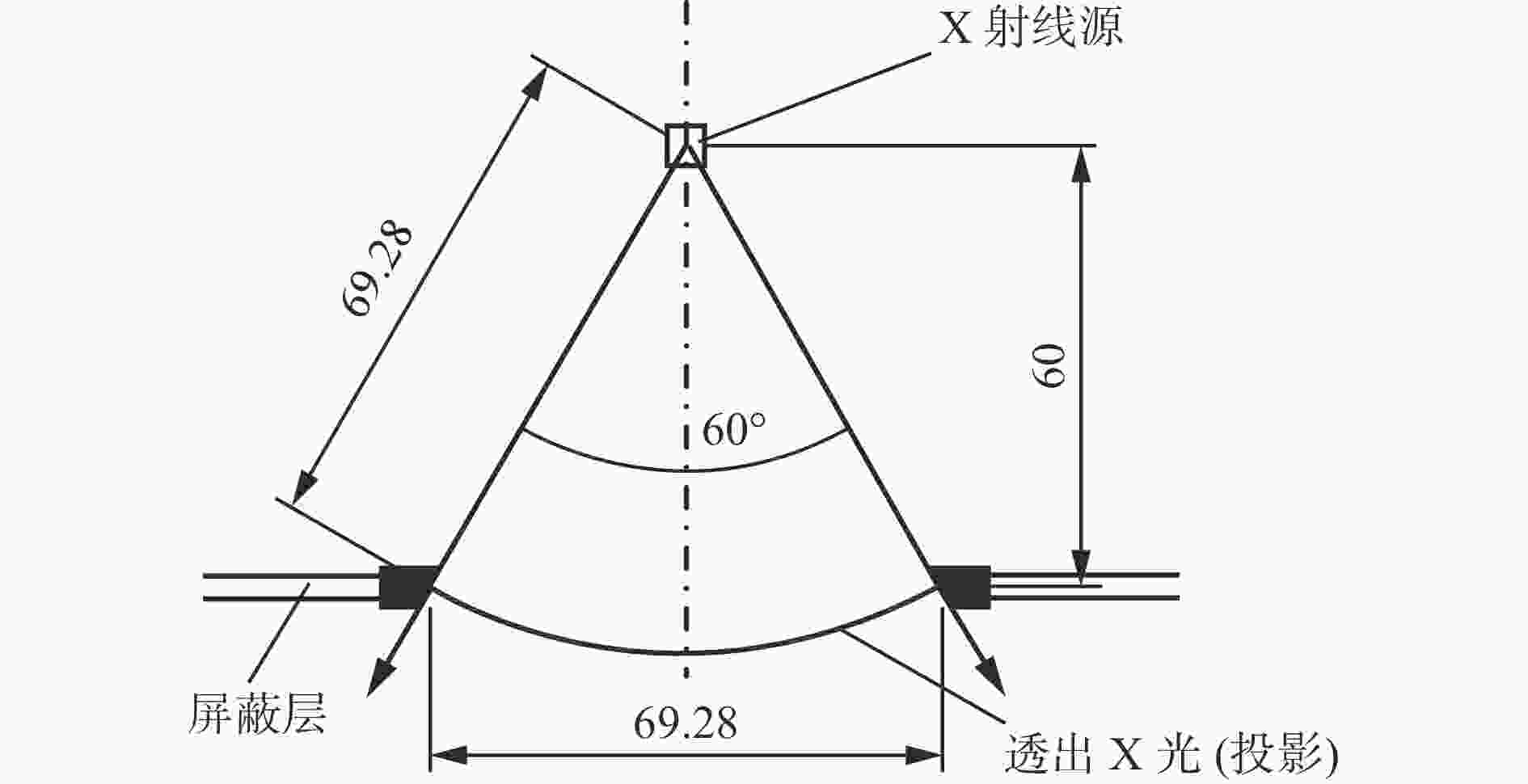

摘要: X射线源是X射线透射式检测的核心组成设备,其稳定性与可靠性决定了X射线透射式检测性能。为满足X射线透射式检测的性能要求,X射线源的管电压宜在100~160 kV之间选取、管电流控制在0.1~4 mA。针对由Q235钢板制造的隔爆外壳会大大降低X射线源辐射输出强度的问题,提出了在矿用X射线源的隔爆外壳上安装钢化玻璃制成的X射线透窗,增加X射线的透射率。以煤矿选矸识别透射式检测领域应用的X射线源最大管电压160 kV、最大管电流4 mA为例,通过实测计算出矿用X射线源的最大辐射输出功率约为50 mW,满足GB/T 3836.22—2017《爆炸性环境 第22部分:光辐射设备和传输系统的保护措施》规定的辐射功率不超过150 mW的要求。为降低矿用X射线源工作温度升高的风险,提出了X射线管宜选用导热性能好的陶瓷壳体,X射线管阳极与金属外壳直接固定以增加散热效果,利用X射线透窗来减少X射线管阳极电流产生的热功率,从而保证矿用X射线源的隔爆外壳表面温度小于GB/T 3836.1—2021《爆炸性环境 第1部分:设备 通用要求》规定的150 ℃限值。为避免矿用X射线源对周围环境产生辐射影响,提出了将X射线管安装在用3 mm厚不锈钢+5 mm厚金属铅制成的铅室中,以屏蔽非工作区域的X射线,从而保证矿用X射线源的非工作区域X射线泄漏的剂量当量率小于GBZ 125—2009《含密封源仪表的放射卫生防护要求》规定的2.5 µSv/h限值。Abstract: The X-ray source is the core component equipment of X-ray transmission detection. The stability and reliability of the X-ray source determine the performance of X-ray transmission detection. In order to meet the performance requirements of X-ray transmission detection, the tube voltage of X-ray source should be selected between 100-160 kV, and the tube current should be controlled between 0.1-4 mA. In view of the problem that the flameproof shell made of Q235 steel plate can greatly reduce the radiation output intensity of X-ray source, the X-ray transparent window made of tempered glass is installed on the flameproof shell of mine X-ray source to increase the transmission rate of X-ray. Taking the maximum tube voltage of 160 kV and the maximum tube current of 4 mA of X-ray source applied in the field of coal mine gangue selection identification transmission detection as an example, the maximum radiation output power of the mine X-ray source is calculated to be about 50 mW through actual measurement. The result meets the requirements of GB/T 3836.22-2017 Explosive Atmospheres-Part 22: Protection of Equipment and Transmission System Using Optical Radiation which stipulates that the radiation power shall not exceed 150 mW. In order to reduce the risk of the working temperature rise of the mine X-ray source, it is proposed that the X-ray tube should be made of the ceramic shell with good thermal conductivity. The anode of the X-ray tube should be directly fixed to the metal shell to increase the heat dissipation effect. The X-ray transparent window should be used to reduce the thermal power generated by the anode current of the X-ray tube. This will ensure that the surface temperature of the flameproof shell of the mine X-ray source is less than the 150 ℃ limit specified in GB/T 3836.1-2021 Explosive Atmospheres-Part 1: Equipment-General Requirements. In order to avoid the radiation impact of mine X-ray source on the surrounding environment, it is proposed to install the X-ray tube in a lead chamber made of 3 mm thick stainless steel and 5 mm thick metallic lead. This will shield the X-ray in non-working area, so as to ensure that the dose equivalent rate of X-ray leakage in the non-working area of the mine X-ray source is less than 2.5 µSv/h limit specified in GBZ 125-2009 Radiological Protection Requirements for Gauges Containing Sealed Radioactive Source.

-

表 1 不同管电压下钨靶的X射线转换效率

Table 1. X-ray conversion efficiency of tungsten target under different tube voltages

管电压/kV 辐射能量转换效率/% 热能转换效率/% 100 0.74 99.26 120 0.89 99.11 140 1.04 98.96 160 1.18 98.82 200 1.48 98.52 表 2 管电压为100 kV时X射线穿过钢板的透射率

Table 2. Transmittance of X-ray through steel plate at 100 kV tube voltage

钢板数量 钢板厚度/mm 信号电压/V 透射率/% 1 1 0.409 9 25.79 2 2 0.188 1 11.84 3 3 0.099 3 6.25 4 4 0.056 6 3.56 5 5 0.033 9 2.13 表 3 管电压为120 kV时X射线穿过钢板的透射率

Table 3. Transmittance of X-ray through steel plate at 120 kV tube voltage

钢板数量 钢板厚度/mm 信号电压/V 透射率/% 1 1 0.731 3 31.25 2 2 0.375 7 16.06 3 3 0.218 7 9.35 4 4 0.137 1 5.86 5 5 0.090 1 3.85 表 4 管电压为160 kV时X射线穿过钢板的透射率

Table 4. Transmittance of X-ray through steel plate at 160 kV tube voltage

钢板数量 钢板厚度/mm 信号电压/V 透射率/% 1 1 1.618 4 40.57 2 2 0.902 6 22.63 3 3 0.523 8 13.13 4 4 0.273 1 6.85 5 5 0.264 4 6.63 表 5 管电压为100 kV时X射线穿过钢化玻璃的透射率

Table 5. Transmittance of X-ray through tempered glass at 100 kV tube voltage

玻璃数量 玻璃厚度

/mm信号电压/V 透射率/% 1 1.93 1.229 5 77.37 2 3.86 0.992 9 62.48 3 5.79 0.821 3 51.68 4 7.72 0.689 8 43.41 5 9.65 0.585 0 36.81 表 6 管电压为120 kV时X射线穿过钢化玻璃的透射率

Table 6. Transmittance of X-ray through tempered glass at 120 kV tube voltage

玻璃数量 玻璃厚度/mm 信号电压/V 透射率/% 1 1.93 1.868 0 79.83 2 3.86 1.544 0 65.98 3 5.79 1.302 0 55.64 4 7.72 1.109 0 47.39 5 9.65 0.955 9 40.85 表 7 管电压为160 kV时X射线穿过钢化玻璃的透射率

Table 7. Transmittance of X-ray through tempered glass at 160 kV tube voltage

玻璃数量 玻璃厚度/mm 信号电压/V 透射率/% 1 1.93 3.392 5 85.04 2 3.86 2.655 9 66.58 3 5.79 2.316 3 58.07 4 7.72 2.177 8 54.59 5 9.65 1.730 5 43.38 表 8 X射线管常见壳体材料的主要性能指标

Table 8. Main performance indexes of common shell materials of X-ray tube

性能 玻璃 陶瓷 抗拉强度/MPa 80~200 150~500 热膨胀系数/(10−6K−1) 3~13 5~10 电阻率/(Ω·m) 107~108 1012~1013 介电强度/(MV·m−1) 30~60 150~250 导热系数/(W·cm−1·K−1) 0.0042~0.0250 0.025~2.100 软化温度/ ℃ 490~700 1 200~1 900 长期使用温度/℃ 150~250 800~1700 表 9 不同管电压时X射线穿过屏蔽铅板的透射率

Table 9. Transmittance of X-ray through shielded lead plate at different tube voltages

管电压/kV 透射率/% 1 mm厚铅板 2 mm厚铅板 3 mm厚铅板 90 0.410 0 0.017 0 0.000 8 100 0.740 0 0.052 0 0.004 1 125 1.100 0 0.081 0 0.008 0 150 1.300 0 0.094 0 0.011 0 160 1.476 4 0.113 6 0.013 4 -

[1] 张燕超,徐桂云,崔吉. 基于X射线数字成像技术的钢丝绳检测系统[J]. 无损探伤,2007,31(1):23-24. doi: 10.3969/j.issn.1671-4423.2007.01.005ZHANG Yanchao,XU Guiyun,CUI Ji. System used to detect steel wire rope based on X-ray digital imaging technology[J]. Nondestructive Testing Technology,2007,31(1):23-24. doi: 10.3969/j.issn.1671-4423.2007.01.005 [2] 阮炜,郑明山. X射线检测钢丝绳成像系统设计[J]. 自动化技术与应用,2005(12):62-64. doi: 10.3969/j.issn.1003-7241.2005.12.021RUAN Wei,ZHENG Mingshan. Fault detection system for steel wire rope[J]. Techniques of Automation and Applications,2005(12):62-64. doi: 10.3969/j.issn.1003-7241.2005.12.021 [3] 马宏伟,毛清华,张旭辉. 矿用强力带式输送机智能监控技术研究进展[J]. 振动. 测试与诊断,2016,36(2):213-219,396.MA Hongwei,MAO Qinghua,ZHANG Xuhui. Intelligent monitoring technology study process for steel cord conveyor belt in coal mine[J]. Journal of Vibration,Measurement & Diagnosis,2016,36(2):213-219,396. [4] LI Xianguo, MIAO Changyun, WANG Ji, et al. Automatic defect detection method for the steel cord conveyor belt based on its X-ray images[C]. The 2nd Asia-Pacific Conference on Wearable Computing Systems, Changsha, 2011: 536-539. [5] 崔广鑫,张宏伟. 基于X射线的钢丝绳芯输送带监测系统设计[J]. 工矿自动化,2012,38(4):70-72.CUI Guangxin,ZHANG Hongwei. Design of monitoring system of conveyor belt of steel rope core based on X-ray[J]. Industry and Mine Automation,2012,38(4):70-72. [6] 于中山. 基于X射线图像处理的煤矸识别技术研究[D]. 淮南: 安徽理工大学, 2020.YU Zhongshan. Research on recognition technology of coal and gangue based on X-ray image processing[D]. Huainan: Anhui University of Science and Technology, 2020. [7] ROBBEN C,KORTE J,WOTRUBA H,et al. Experiences in dry coarse coal separation using X-ray-transmission-based sorting[J]. International Journal of Coal Preparation and Utilization,2014,34(3/4):210-219. [8] 黄松,王敏,张静. X射线智能选矸技术在姚桥选煤厂的应用分析[J]. 山东煤炭科技,2020,38(8):186-188,197. doi: 10.3969/j.issn.1005-2801.2020.08.060HUANG Song,WANG Min,ZHANG Jing. Application of X-ray intelligent gangue separation technology in Yaoqiao Coal Preparation Plant[J]. Shandong Coal Science and Technology,2020,38(8):186-188,197. doi: 10.3969/j.issn.1005-2801.2020.08.060 [9] 田冰. X射线称重原理与实现方法[J]. 上海电气技术,2012,5(3):53-58. doi: 10.3969/j.issn.1674-540X.2012.03.012TIAN Bing. Weighing principle and method of X-ray[J]. Journal of Shanghai Electric Technology,2012,5(3):53-58. doi: 10.3969/j.issn.1674-540X.2012.03.012 [10] 任凤国,刘学红,任安祥,等. 提高矿用X射线核子秤计量稳定性的研究[J]. 工矿自动化,2018,44(8):24-27. doi: 10.13272/j.issn.1671-251x.2018010058REN Fengguo,LIU Xuehong,REN Anxiang,et al. Research on improving measurement stability of mine-used X-ray nuclear scale[J]. Industry and Mine Automation,2018,44(8):24-27. doi: 10.13272/j.issn.1671-251x.2018010058 [11] 张秀峰,李太友. X射线灰分仪在选煤厂的应用分析[J]. 选煤技术,2020,48(3):22-26. doi: 10.16447/j.cnki.cpt.2020.03.006ZHANG Xiufeng,LI Taiyou. Application and analysis of the X-ray ash monitor in coal preparation plant[J]. Coal Preparation Technology,2020,48(3):22-26. doi: 10.16447/j.cnki.cpt.2020.03.006 [12] KETELHODT L,BERGMANN C. Dual energy X-ray transmission sorting of coal[J]. Journal of The Southern African Institute of Mining and Metallurgy,2010,110(7):371-378. [13] 王鹏程. 放射物理与防护[M]. 2版. 北京: 人民卫生出版社, 2009.WANG Pengcheng. Radioactive physics and protection[M]. 2nd ed. Beijing: People's Medical Publishing House, 2009. [14] 范建中,杨金文. 用X射线实验仪研究X射线的衰减规律[J]. 太原师范学院学报(自然科学版),2011,10(3):95-98.FAN Jianzhong,YANG Jinwen. Application X-ray experiment to physics experiment teaching in college[J]. Journal of Taiyuan Normal University(Natural Science Edition),2011,10(3):95-98. [15] WANG Wenqing. Study of penetration window technology of explosion proof γ ray detector[J]. Journal of Convergence Information Technology,2012,7(15):366-374. doi: 10.4156/jcit.vol7.issue15.43 [16] 陈捷频,陈钧. 隔爆外壳上玻璃透明件的无应力安装设计[J]. 电气防爆,2009(3):1-5. doi: 10.3969/j.issn.1004-9118.2009.03.001CHEN Jiepin,CHEN Jun. The flameproof installation design of transparent glass in explosion-proof enclosure without stress[J]. Electrical Explosion Protection,2009(3):1-5. doi: 10.3969/j.issn.1004-9118.2009.03.001 [17] GB/T 3836.22—2017 爆炸性环境 第22部分: 光辐射设备和传输系统的保护措施[S].GB3836.22-2017 Explosive atmospheres-part 22: protection of equipment and transmission system using optical radiation[S]. [18] 尹晓冬, 王福合. 物理学与世界进步[M]. 合肥: 安徽教育出版社, 2015.YIN Xiaodong, WANG Fuhe. Physics and world progress[M]. Hefei: Anhui Education Press, 2015. [19] 江源. 光源发展史[J]. 灯与照明,2010,34(1):54-62. doi: 10.3969/j.issn.1008-5521.2010.01.015JIANG Yuan. Evolution history of light source[J]. Light & Lighting,2010,34(1):54-62. doi: 10.3969/j.issn.1008-5521.2010.01.015 [20] 王晶. X射线血液辐照技术及其临床应用[J]. 中国医疗器械信息,2019,25(21):37-39. doi: 10.3969/j.issn.1006-6586.2019.21.014WANG Jing. X-ray blood irradiation technique and its clinical applications[J]. China Medical Device Information,2019,25(21):37-39. doi: 10.3969/j.issn.1006-6586.2019.21.014 [21] JANATPOUR K,DENNING L,NELSON K,et al. Comparison of X-ray vs. gamma irradiation of CPDA-1 red cells[J]. Vox Sanguinis,2005,89(4):215-219. doi: 10.1111/j.1423-0410.2005.00699.x [22] DODD B,VETTER R J. Replacement of 137Cs irradiators with X-ray irradiators[J]. Health Physics:The Radiation Safety Journal,2009,96(S2):27-30. [23] 杨强. 微型X射线源关键技术研究[D]. 成都: 成都理工大学, 2012.YANG Qiang. Researches on key technologies of miniature X-ray source[D]. Chengdu: Chengdu University of Technology, 2012. [24] 荣吉萍. 工业检测和安全检查用X射线管的现状与发展[J]. 真空电子,2015(1):42-45,50.RONG Jiping. Present situation and development of X-ray tubes for industrial detection and safety inspection[J]. Vacuum Electronics,2015(1):42-45,50. [25] STRAZNICKY I. Thermal modeling:a must at the design phase[J]. The Journal of Military Electronics & Computing,2008(6):16-19. [26] 李昊,项名珠,肖建生. 中等功率X射线源的热设计与热仿真[J]. 机械与电子,2014(7):27-30. doi: 10.3969/j.issn.1001-2257.2014.07.007LI Hao,XIANG Mingzhu,XIAO Jiansheng. Thermal design and simulation for medium-power X-ray source[J]. Machinery & Electronics,2014(7):27-30. doi: 10.3969/j.issn.1001-2257.2014.07.007 -

下载:

下载: